Dyeing accelerant for color matching and dyeing ofpolylactic acid as well as preparation method and application of dyeing accelerant

A technology of dyeing accelerator and polylactic acid, which is applied in the field of dyeing and can solve problems such as single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

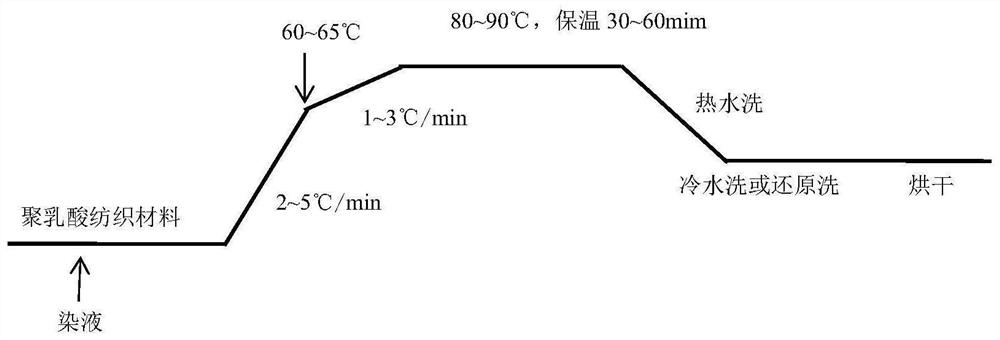

Method used

Image

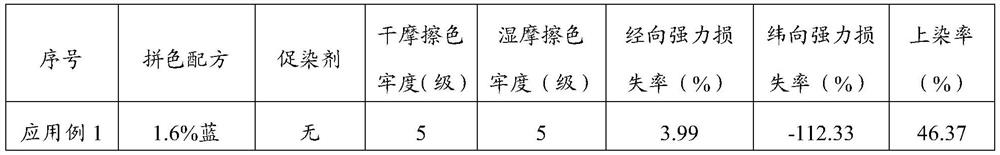

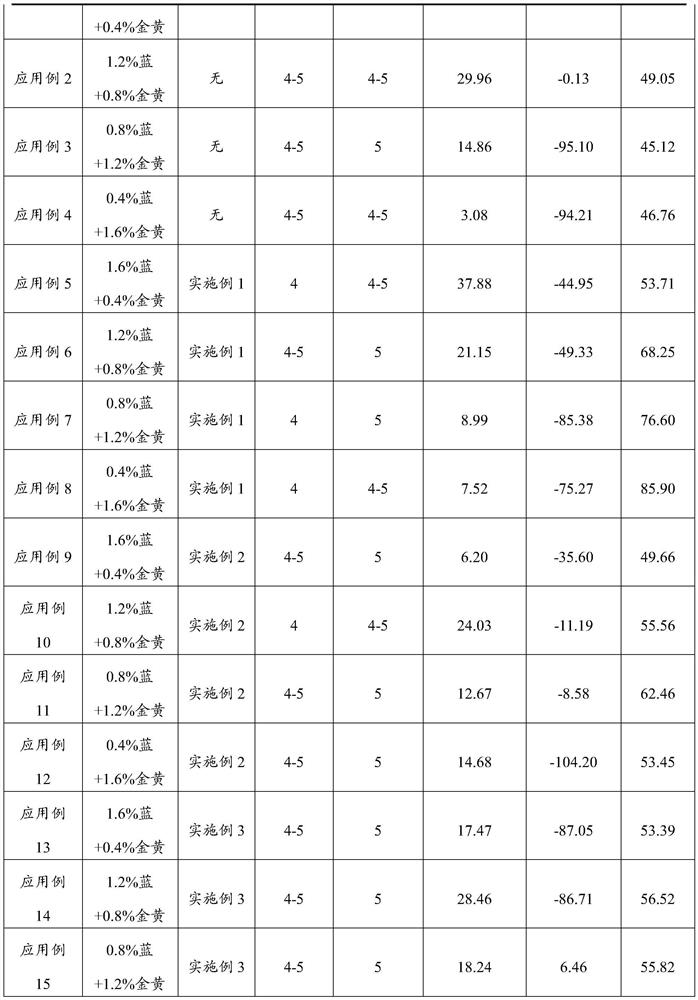

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a dye accelerator for polylactic acid color matching dyeing described in the above technical solution, comprising: mixing water at 70-100°C with ethyl salicylate, then adding citric acid, diethylene Triaminepentamethylenephosphonic acid, ethyl benzoate and ethyl propionate, resulting in dye accelerators for color block dyeing of polylactic acid.

[0047]The invention mixes water at 70-100°C with ethyl salicylate to obtain a mixed solution. In the present invention, controlling the temperature of the water at 70-100° C. is beneficial to improving the compatibility of the system, and further beneficial to obtaining a stable and uniform dyeing accelerator. In the present invention, the mixing of the water and ethyl salicylate is preferably carried out under stirring; the stirring speed is preferably 600-1500r / min, more preferably 800-1200r / min; the stirring The time is preferably 3 to 5 minutes.

[0048] After th...

Embodiment 1

[0071] Raw materials (parts by weight): 50 parts of ethyl salicylate, 25 parts of ethyl benzoate, 10 parts of diethylenetriaminepentamethylenephosphonic acid, 5 parts of citric acid, 5 parts of ethyl propionate and 50 parts of deionized water share;

[0072] Add ethyl salicylate to deionized water at 70°C, stir for 5 minutes at a rate of 800 r / min, then add citric acid and diethylenetriaminepentamethylenephosphonic acid, continue stirring for 3 minutes, and finally add ethyl benzoate and acrylic acid Acetate ethyl ester, continue to stir 15min, obtain the dyeing accelerator that is used for polylactic acid color matching dyeing.

Embodiment 2

[0074] Raw materials (parts by weight): 10 parts of ethyl salicylate, 10 parts of ethyl benzoate, 5 parts of diethylenetriaminepentamethylenephosphonic acid, 3 parts of citric acid, 3 parts of ethyl propionate and 50 parts of deionized water share;

[0075] Adopt the same preparation method as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com