Anti-frost heaving system for vertical shaft in cold region and construction method of anti-frost heaving system

A construction method and anti-frost heaving technology, which is applied in vertical shaft equipment, sinking, and earthwork drilling and mining, can solve the problems of inconvenient drilling of vertical shaft equipment, difficult construction in permafrost layers, large manpower and financial resources, etc., and achieve good economical and economical performance. The effect of use value, simple structure and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In a cold area, the lowest temperature can reach minus 20°C, and the soft soil layer is perennial seasonal frozen soil layer with a thickness of 5m. In case of thawing and frost heaving, wellhead collapse and deformation may occur, making it unsafe to use.

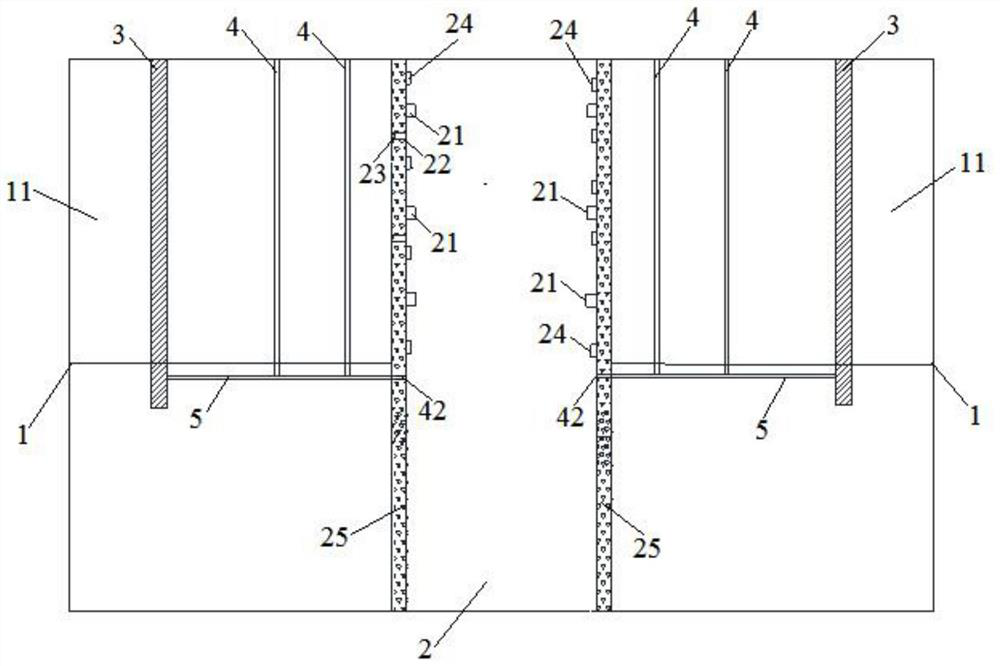

[0044] For this reason, embodiment 1 provides a kind of frost-heave anti-freezing system of vertical well in cold area, comprises vertical shaft 2 that is arranged in surrounding rock 1; Also comprises partition wall 3; Surrounding; the partition wall 3 is a concrete anti-seepage partition wall, and the strength of the partition wall 3 is C30.

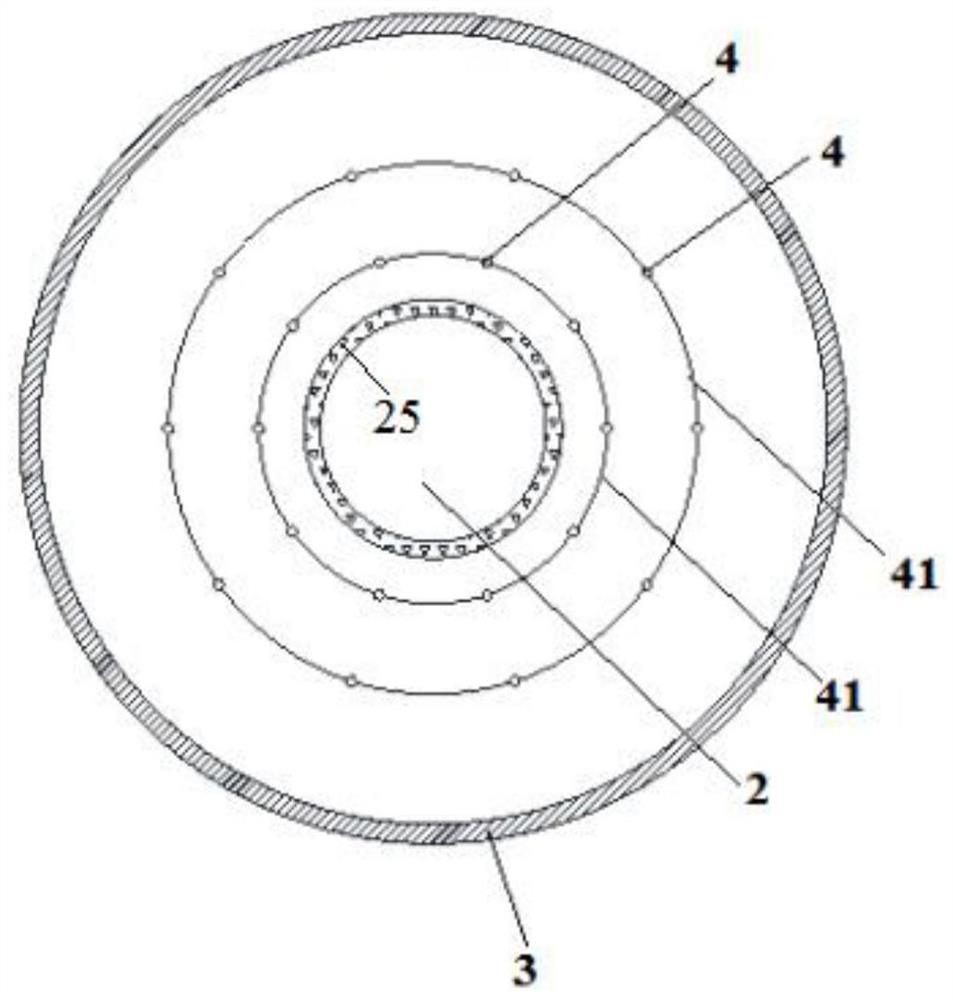

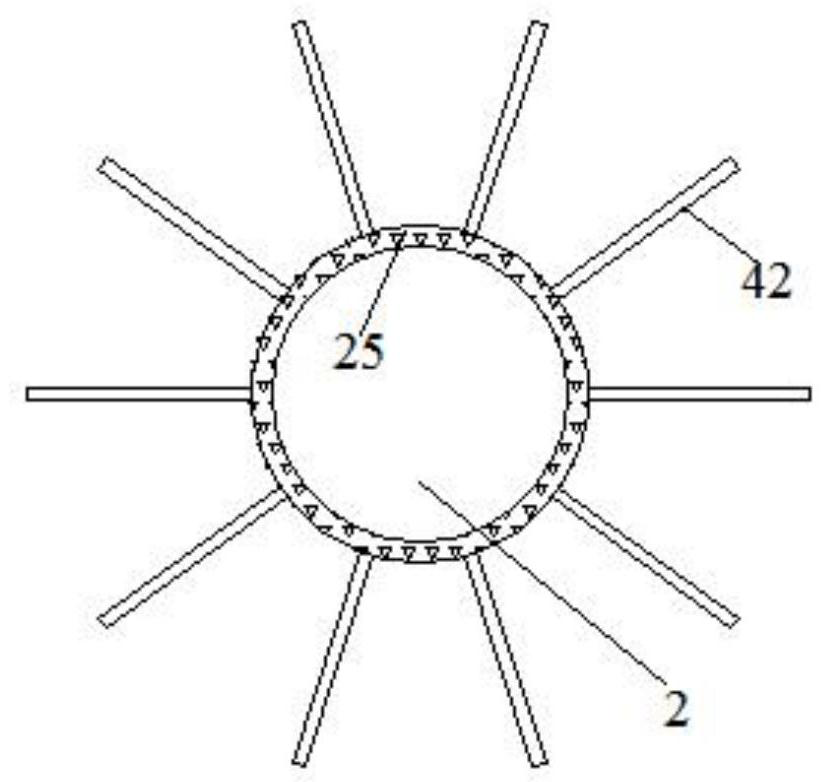

[0045] Such as figure 1 and figure 2As shown, two rings of liquid injection walls 41 are arranged between the separation wall 3 and the shaft, and each ring of liquid injection walls 41 is composed of a number of evenly spaced liquid injection holes 4 arranged near the shaft 2 The distance between the liquid injection wall 41 and the vertical shaft 2 is 1m, and in the li...

Embodiment 2

[0053] Example 2 provides the implementation method of the above-mentioned anti-frost heave structure. The lowest temperature in a certain place can reach minus 20°C all year round. The inventor simulates the environment of minus 20°C indoors, and adjusts the influence of solvents with different mass concentrations on the freezing point of water, and finally determines when When the mass fraction of the alcohol solution is more than 37%, when the mass concentration of the sodium chloride solution is more than 23%, and when the mass concentration of the calcium chloride solution reaches more than 21%, the water will not freeze at minus 20°C.

[0054] Include the following steps:

[0055] Step 1. Start construction when the outdoor temperature is minus 18°C during the low climate period in the cold region. First, mark the positions of the shaft 2 and the separation wall 3, and build the separation wall 3;

[0056] Step 2, excavate the shaft 2, and install several temperature m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com