Preparation method and preparation device of metal niobium nanopowder

A nano-powder and preparation device technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unfavorable industrial production, high preparation cost, low preparation yield, etc. The effect of lower product price and simple equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

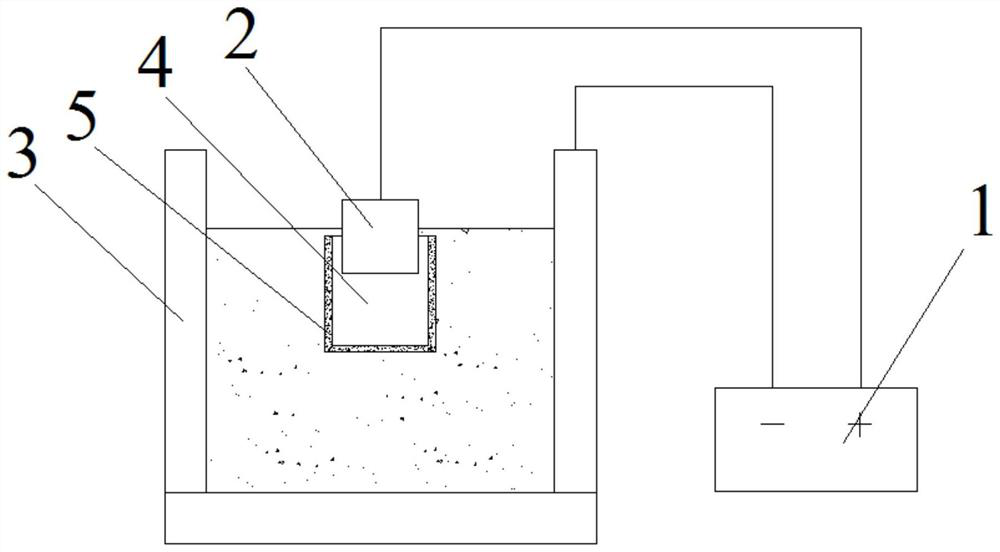

[0028] Specific implementation mode one: refer to Figure 1 to Figure 4 Describe this embodiment mode, this embodiment mode provides a kind of preparation device of metal niobium nanopowder, it is characterized in that: described preparation device comprises adjustable DC power supply 1, fixture 2 and reaction vessel 3, fixture 2 connects adjustable DC power supply through wire The positive pole of the power supply 1 is connected, and the reaction vessel 3 is connected with the negative pole of the adjustable DC power supply 1 through a wire;

[0029] The adjustable DC power supply 1 is connected to an oscilloscope, and the oscilloscope is used to analyze the waveform of the power supply, and a rectification component is arranged between the positive pole of the adjustable DC power supply 1 and the fixture 2;

[0030] The material of the clamp 2 is the same as that of the workpiece to be processed.

[0031] In this embodiment, the reaction vessel 3 is provided with a temperat...

specific Embodiment approach 2

[0032] Specific implementation mode two: refer to Figure 1 to Figure 4 Describe this embodiment. This embodiment is to further limit the rectifying component described in the first specific embodiment. In this embodiment, the rectifying component between the positive pole of the adjustable DC power supply 1 and the clamp 2 is a diode. The diode is connected in series between the positive pole of the adjustable DC power supply 1 and the fixture 2 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Specific implementation mode three: refer to Figure 1 to Figure 4 Describe this embodiment. This embodiment is to further limit the rectifying component described in the second specific embodiment. In this embodiment, the rectifying component between the positive pole of the adjustable DC power supply 1 and the clamp 2 is a capacitor, and the capacitor is connected in parallel At both ends of the workpiece to be processed, one end of the capacitor is connected to the fixture 2 , and the other end of the capacitor is connected to the reaction container 3 . Other compositions and connection methods are the same as those in the second embodiment.

[0034] Combined with the description in the second and third embodiments, the waveform of the original power supply is analyzed by an oscilloscope, and it is found that the rectification effect of the power waveform is not good, and the output DC waveform is unstable. The method improves the rectified waveform to meet the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com