Process for producing plywood by using small fragmental veneers

A plywood and veneer technology, which is applied in the jointing of wooden veneers, other plywood/plywood appliances, applications, etc., can solve the problems of increasing production time, unfavorable production efficiency, unfavorable board durability, etc., to reduce production time, It is beneficial to production efficiency and increases the effect of eating nails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

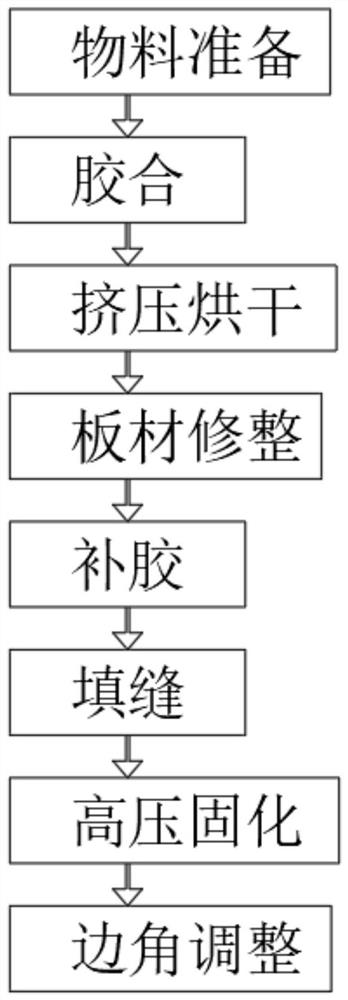

Image

Examples

Embodiment 1

[0021] Step 1. Material preparation: peel the logs, cut them into chips, and then dry them in the sun. Grind the collected small veneers to the same thickness, clean up the wood chips on the materials, soften and flatten the boards, Panels are cut to the desired size;

[0022] Step 2, gluing: Put adhesive on the upper surface of the lower panel, arrange the trimmed small veneers on the upper surface of the lower panel, carry out extrusion pre-solidification, and then glue the broken small veneers on the lower panel Adhesive, extruding the lower surface of the upper panel to the upper surface of the broken small veneer for extrusion pre-solidification;

[0023] Step 3. Squeeze and dry: Place the glued plywood neatly, stack the plywood through the shelf, pressurize, and place it in the drying room for drying;

[0024] Step 4. Board trimming: Saw the edge of the extruded and dried board to obtain regular plywood, grind the corners of the board, polish the upper and lower layers ...

Embodiment 2

[0030] Step 1. Material preparation: peel the logs, cut them into chips, and then dry them in the sun. Grind the collected small veneers to the same thickness, clean up the wood chips on the materials, soften and flatten the boards, Panels are cut to the desired size;

[0031] Step 2, gluing: Put adhesive on the upper surface of the lower panel, arrange the trimmed small veneers on the upper surface of the lower panel, carry out extrusion pre-solidification, and then glue the broken small veneers on the lower panel Adhesive, extruding the lower surface of the upper panel to the upper surface of the broken small veneer for extrusion pre-solidification;

[0032] Step 3. Squeeze and dry: Place the glued plywood neatly, stack the plywood through the shelf, pressurize, and place it in the drying room for drying;

[0033] Step 4. Board trimming: Saw the edge of the extruded and dried board to obtain regular plywood, grind the corners of the board, polish the upper and lower layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com