Domestic sewage treatment agent capable of efficiently removing phosphorus and preparation method thereof

A treatment agent and ultra-pure water technology, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult treatment, high treatment cost, and weak descaling effect , to achieve the effects of simplifying raw material allocation, optimizing the preparation process, and reducing the risk of heavy metals exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

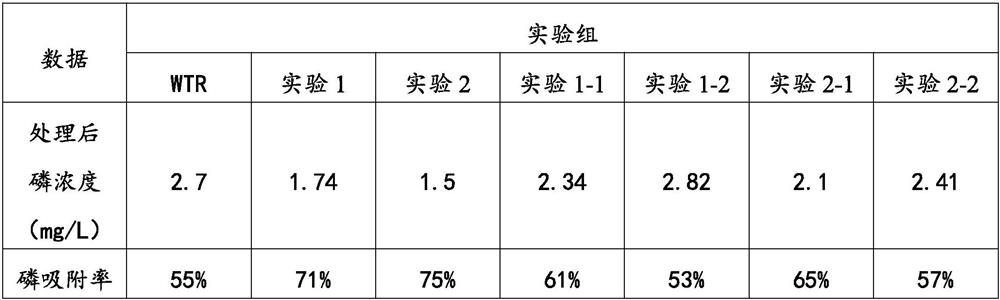

Examples

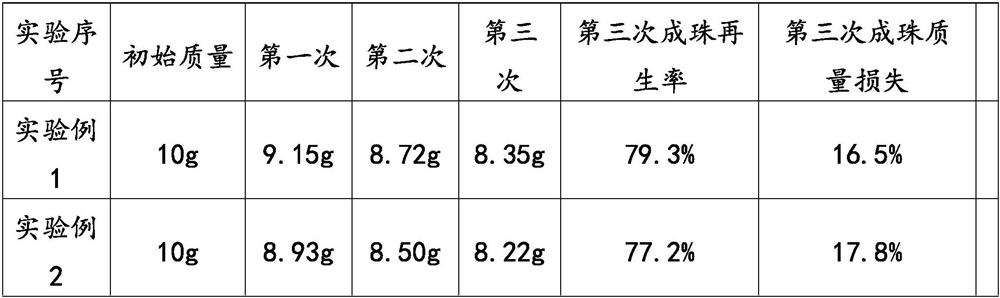

Embodiment 1

[0033] The preparation method of modified WTR comprises the following steps:

[0034] S1: Add WTR to Na 2 SO 4 solution, stirred for 6-8h; the WTR and Na 2 SO 4 The solid-liquid mass ratio of the solution is 1:20-30, Na 2 SO 4 The concentration of the solution is 0.1-0.5mol / L; the specific operation of the stirring reaction is as follows: stir slowly for 1-3 minutes, and then stir at a speed of 150-180r / min in a water bath environment of 30°C.

[0035] S2: After the stirring reaction is completed, centrifugally filter and wash with ultrapure water to remove residual Na 2 SO 4 , get WTR filtrate;

[0036] S3: Dry the WTR filtrate in an environment of 90-110°C for 10-12 hours. 2 Calcined at 350-450° C. for 3-5 hours under gas protection, and cooled to obtain modified WTR.

[0037] The preparation method of modified WTR sodium alginate beads comprises the following steps,

[0038] Adding the modified WTR to ultrapure water, placing it under an ultrasonic instrument and ...

Embodiment 2

[0042] The preparation method of modified WTR comprises the following steps:

[0043] S1: Add WTR to Na 2 SO 4 solution, stirred for 6-8h; the WTR and Na 2 SO 4 The solid-liquid mass ratio of the solution is 1:20-30, Na 2 SO 4 The concentration of the solution is 0.1-0.5mol / L; the specific operation of the stirring reaction is to first stir slowly for 1-3 minutes, and then stir at a speed of 150-180r / min in a water bath environment of 30±3°C.

[0044] S2: After the stirring reaction is completed, centrifugally filter and wash with ultrapure water to remove residual Na 2 SO 4 , get WTR filtrate;

[0045] S3: Dry the WTR filtrate in an environment of 90-110°C for 10-12 hours. 2 Calcined at 350-450° C. for 3-5 hours under gas protection, and cooled to obtain modified WTR.

[0046] The preparation method of modified WTR sodium alginate beads comprises the following steps,

[0047] Adding the modified WTR to ultrapure water, placing it under an ultrasonic instrument and u...

Embodiment 3

[0051] The preparation method of modified WTR comprises the following steps:

[0052] S1: Add WTR to Na 2 SO 4 solution, stirring reaction 6h; the WTR and Na 2 SO 4 The solid-to-liquid mass ratio of the solution is 1:20, and Na 2 SO 4 The concentration of the solution is 0.1 mol / L; the specific operation of the stirring reaction is to stir slowly for 1 min, then stir at a speed of 150 r / min in a water bath environment of 30±1°C.

[0053] S2: After the stirring reaction is completed, centrifugally filter and wash with ultrapure water to remove residual Na 2 SO 4 , get WTR filtrate;

[0054] S3: Dry the WTR filtrate at 90°C for 10 hours, after drying in the muffle furnace, pass through the tube furnace N 2 Calcined at 350°C for 3h under gas protection, and cooled to obtain modified WTR.

[0055] The preparation method of modified WTR sodium alginate beads comprises the following steps,

[0056] Add the modified WTR to ultrapure water, place it under an ultrasonic instr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com