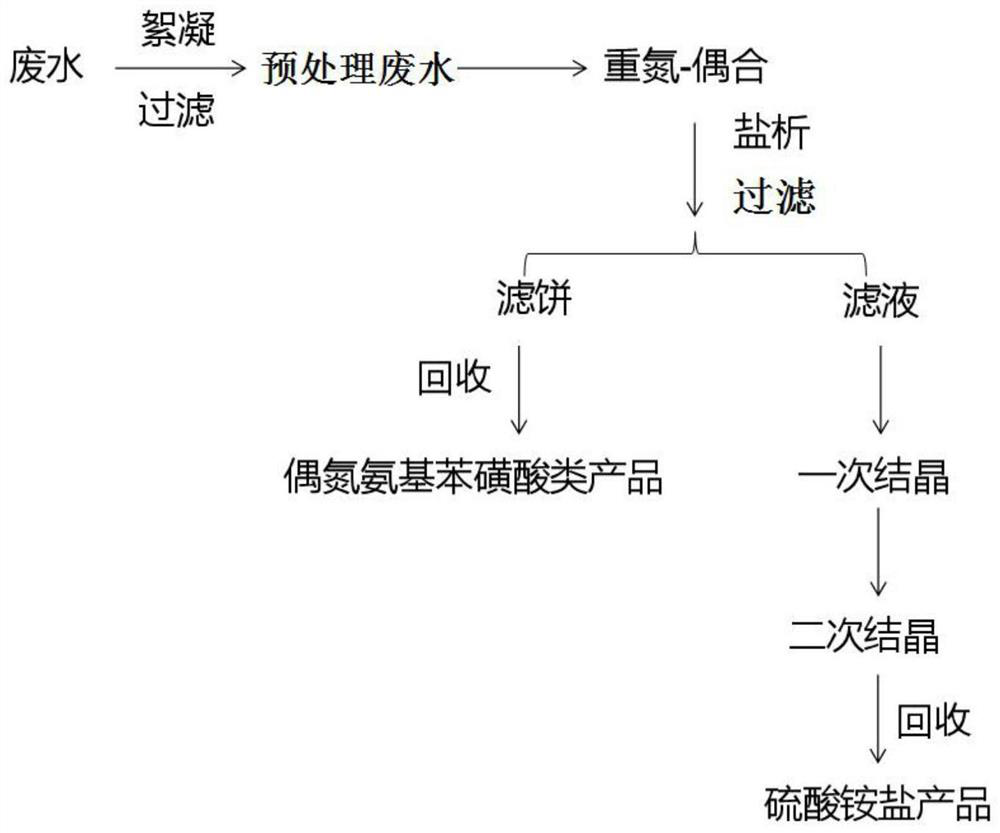

Method for treating wastewater in DNS acid reduction section

A treatment method and technology for wastewater, applied in water/sewage treatment, natural water treatment, neutralized water/sewage treatment, etc., can solve problems such as difficulty in obtaining ideal results, and achieve the effect of improving resource utilization and COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Metabis waste water produced in the reduction section of a DSD acid production enterprise in Henan, of which COD 44000mg / L, salt content 9.6wt% (ammonium salt is the main component), sodium 2,4-diaminobenzenesulfonate (referred to as metabis) The content is 4500mg / L, and the acid content is 27wt% (sulfuric acid is the main component).

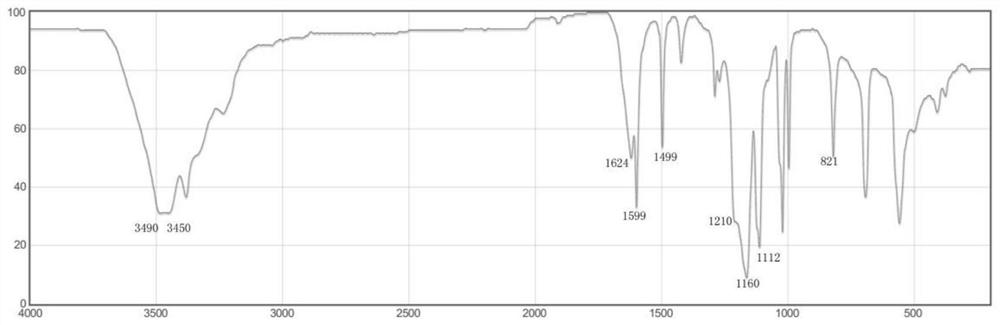

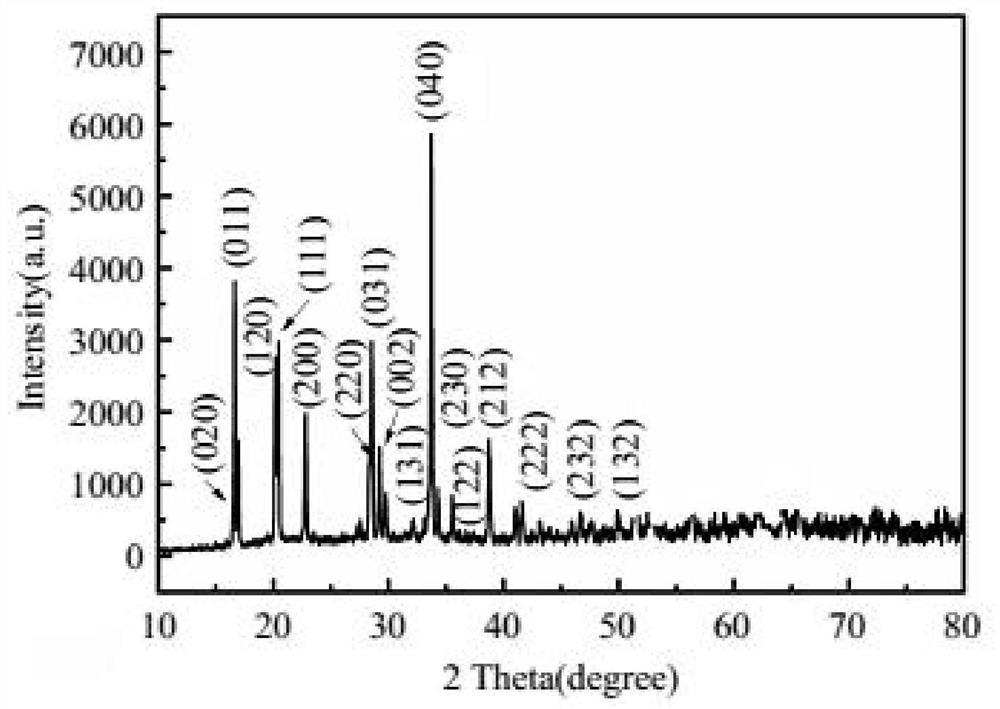

[0066] To 2L of wastewater, add 6mL of 10wt% PAC solution, stir at 400rpm for 10min, add 15mL of 1.5wt‰ anionic PAM (weight average molecular weight 8 million), stir rapidly at 700rpm for 30s, stop stirring, let stand for 30min, settle, and filter. Take 1L of pretreated wastewater and control the temperature at 10°C, slowly add 10wt% NaNO dropwise at 3mL / min 2 50 g of the solution (pH=4) was stirred at 400 rpm for 1 h, and the end point of the diazotization reaction was detected with starch potassium iodide test paper. Then add an equal volume of 1L of the remaining pretreated waste water, raise the temperature to 20°C, perform the coup...

Embodiment 2

[0072]Meta-bis wastewater produced by a DSD acid production enterprise, in which: COD 20000mg / L, salt content 8.7wt% (ammonium salt is the main component), 2,4-diaminobenzenesulfonate sodium (meta-bis) content 3200mg / L , acid content 22wt% (sulfuric acid is the main component).

[0073] To 2L of wastewater, add 6mL of 5wt% PFC solution, stir at 400rpm for 10min, add 20mL of 1.0wt‰ anionic PAM (weight average molecular weight 10 million), stir rapidly at 750rpm for 30s, stop stirring, let stand for 30min, settle, and filter. Take 1L of pretreated wastewater and control the temperature at 5°C, slowly add 10wt% KNO dropwise at 4mL / min 2 25 g of the solution (pH=4) was stirred at 450 rpm for 1.5 h, and the end point of the diazotization reaction was detected with starch potassium iodide test paper. Then add an equal volume of 1L of pretreated waste water, raise the temperature to 25°C, and perform the coupling reaction for 1.5h. Adjust the coupling reaction system to pH=7 with 28...

Embodiment 3

[0076] Meta-bis wastewater produced by a DSD acid production enterprise in Shaanxi: among them, COD 52000mg / L, salt content 11.2wt% (ammonium salt is the main component), 2,4-diaminobenzenesulfonate sodium (meta-bis) content 3200mg / L L, acid content 30wt% (sulfuric acid is the main component).

[0077] Add 10mL of 10wt% starch flocculant solution to 2L of wastewater, stir at 400rpm for 20min, add 15mL of 1.5wt‰ anionic PAM (weight average molecular weight: 10 million), stir rapidly at 850rpm for 30s, stop stirring, let stand for 30min, settle, and filter. Take 1L of pretreated wastewater and control the temperature at 5°C, slowly add 15wt% Ca(NO 2 ) 2 25 g of the solution (pH=4) was stirred at 400 rpm for 2.0 h, and the end point of the diazotization reaction was detected with starch potassium iodide test paper. Then add an equal volume of 1L of the remaining pretreated waste water, raise the temperature to 27°C, and perform the coupling reaction for 1.5h, adjust the couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com