Preparation method of ceramic matrix composite bolts and pins based on long-rod-shaped prefabricated body structure

A composite material and prefabricated technology, applied in the direction of screws, bolts, nuts, etc., can solve the problems of decreased threaded connection strength, easy broken teeth and other problems, and achieve the effects of short processing time, few weaving processes, and excellent toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

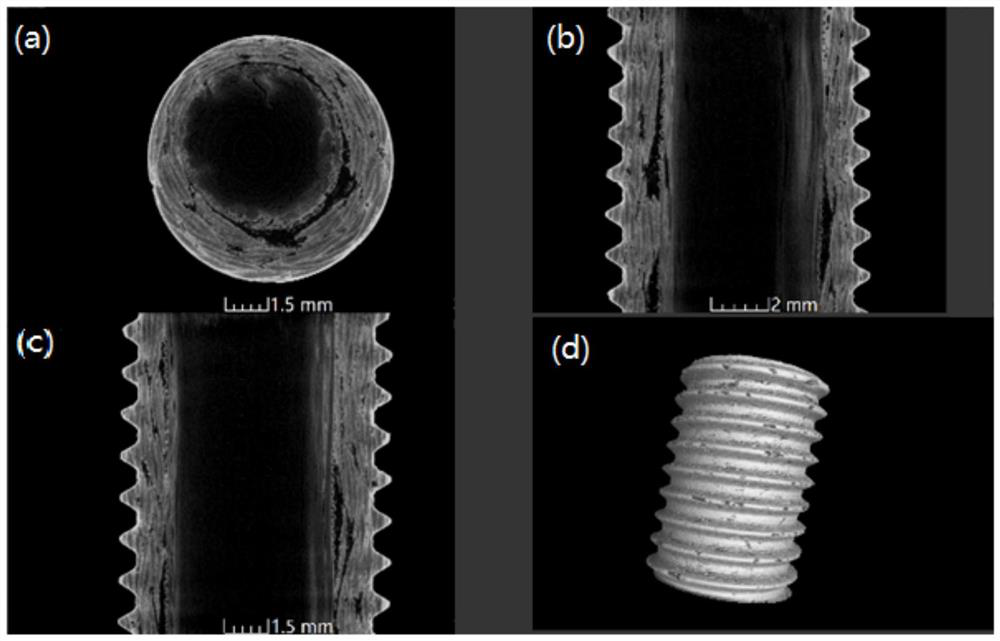

Embodiment 1

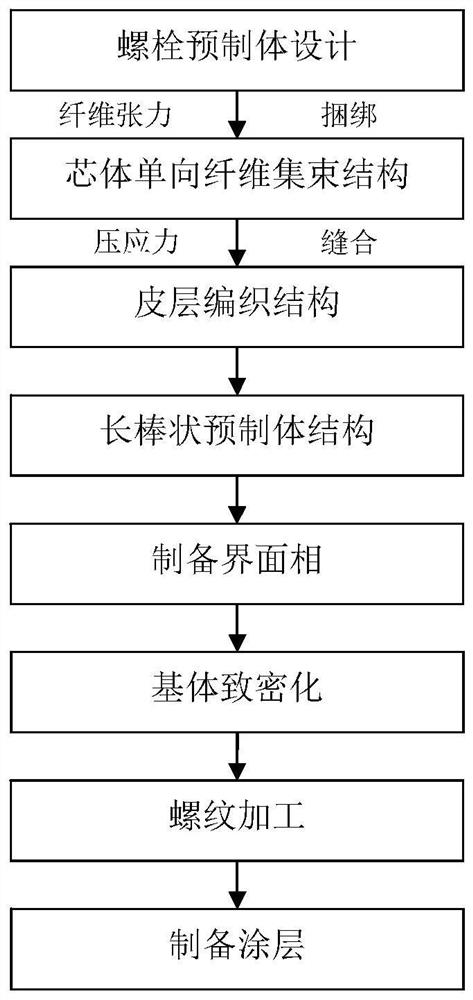

[0093] Such as figure 1 As shown, this embodiment prepares C / SiC ceramic matrix composite bolts through the following steps:

[0094] Step 1: Prefabricated body design;

[0095] According to the size requirements of ceramic matrix composite bolts, design the size of its fiber prefabricated body, wherein the fiber prefabricated body is composed of a core structure and a cladding structure, and the core structure is a cylinder formed by multiple fiber bundles arranged in the same direction; The cladding structure is a tubular fiber bundle braided layer wrapped on the outer peripheral surface of the core structure by a braiding method. The core plays the role of fiber strengthening and toughness, and the cladding plays the role of protection and shaping, and is used to process threads. The fibers may be one or more combinations of carbon fibers, silicon carbide fibers, silicon nitride fibers, and the like.

[0096] In this embodiment, for C / SiC ceramic matrix composite bolts w...

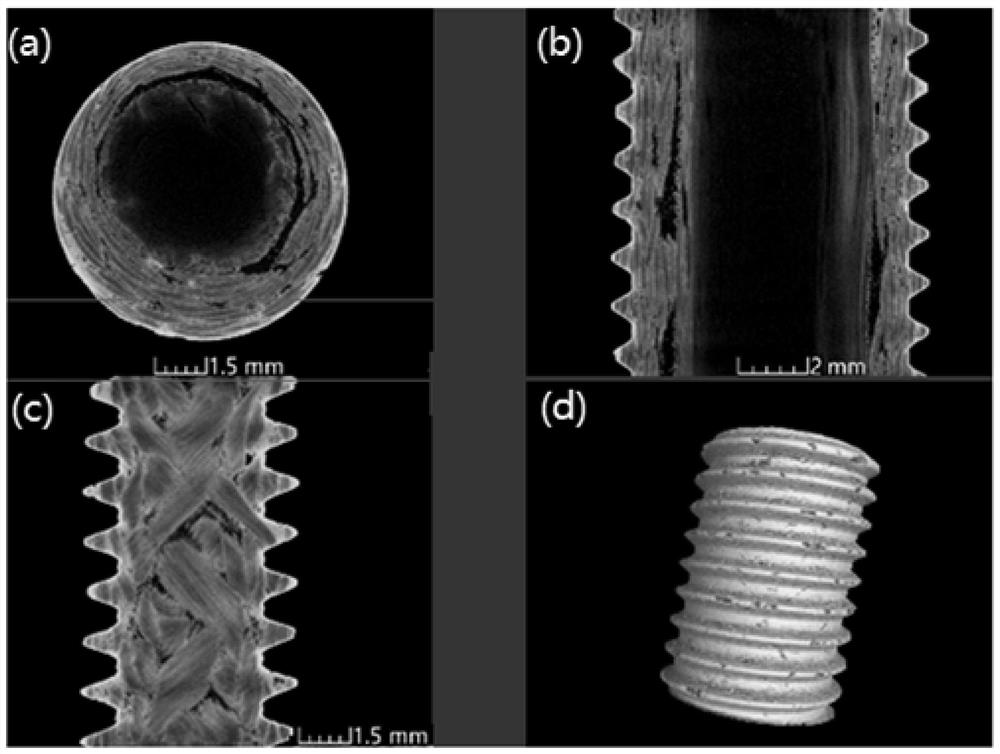

Embodiment 2

[0113] Such as figure 1 As shown, this embodiment prepares C / SiC ceramic matrix composite bolts through the following steps:

[0114] Step 1: Prefabricated body design;

[0115] According to the size requirements of ceramic matrix composite bolts, design the size of its fiber prefabricated body, wherein the fiber prefabricated body is composed of a core structure and a cladding structure, and the core structure is a cylinder formed by multiple fiber bundles arranged in the same direction; The cladding structure is a tubular fiber bundle braided layer wrapped on the outer peripheral surface of the core structure by a braiding method. The core plays the role of fiber strengthening and toughness, and the cladding plays the role of protection and shaping, and is used to process threads. The fibers may be one or more combinations of carbon fibers, silicon carbide fibers, silicon nitride fibers, and the like.

[0116] In this embodiment, for a C / SiC ceramic matrix composite bolt ...

Embodiment 3

[0133] In this example, a C / SiC ceramic matrix composite pin is prepared through the following steps:

[0134] Step 1: Prefabricated body design;

[0135] According to the size requirements of ceramic matrix composite pins, design the size of its fiber prefabricated body, wherein the fiber prefabricated body is composed of a core structure and a cladding structure, and the core structure is a cylinder formed by a plurality of fiber bundles arranged in the same direction; The cladding structure is a tubular fiber bundle braided layer wrapped on the outer peripheral surface of the core structure by weaving; the core plays the role of fiber strengthening and toughening, and the cladding plays the role of protection and shaping. The fibers may be one or more combinations of carbon fibers, silicon carbide fibers, silicon nitride fibers, and the like.

[0136] In this embodiment, for a C / SiC ceramic matrix composite pin with a minor diameter of 6 mm and a major diameter of 8 mm, ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com