Ag-MOF/AuNRs nano composite material as well as preparation and application thereof

A nanocomposite material, self-polymerization technology, applied in the field of Ag-MOF/AuNRs nanocomposite material and its preparation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of AuNRs solution (a method that has been disclosed in the literature) is as follows: take CTAB (cetyltrimethylammonium bromide) and NaOL (sodium oleate) and dissolve them in hot water, and then add them sequentially after cooling AgNO 3 (silver nitrate) solution and HAuCl 4 (tetrachloroauric acid) solution, after mixing evenly, add acid (hydrochloric acid) to adjust, then add ascorbic acid solution and seed solution in turn, and finally stand still to obtain AuNRs solution, wherein the seed solution contains HAuCl with a molar ratio of 2.5:1:6 4 , CTAB and NaBH 4 , CTAB, NaOL, AgNO 3 , HAuCl 4 , ascorbic acid solution, HAuCl in seed solution 4 , CTAB and NaBH in the seed solution 4 The addition ratio is (7.0-9.0)g:(1.3-1.6)g:(0.072-0.096)mM:0.25mM:0.08mM:(0.09-0.18)mM:(36.36-72.72)mM:(0.22-0.44 ) mM. The addition amount ratio is based on the amount taken at the beginning, without considering the reaction between the various compounds durin...

Embodiment 1

[0033] A preparation method of Ag-MOF / AuNRs nanocomposite material, specifically comprising the following steps:

[0034] Mix 2mL of 18mM AuNRs solution with 2mL of 5.5mM 2-aminoterephthalic acid solution, stir at 30°C at a speed of 100rpm for 60min, then slowly add 2mL of 22mM silver acetate solution into the above solution, Stirring at 100rpm at 30°C for 30min, and then standing at 30°C for 24h, followed by centrifugation at 7000rpm for 30min, washing with ethanol, and vacuum drying at 60°C for 8h to obtain Ag-MOF / AuNRs nanocomposites.

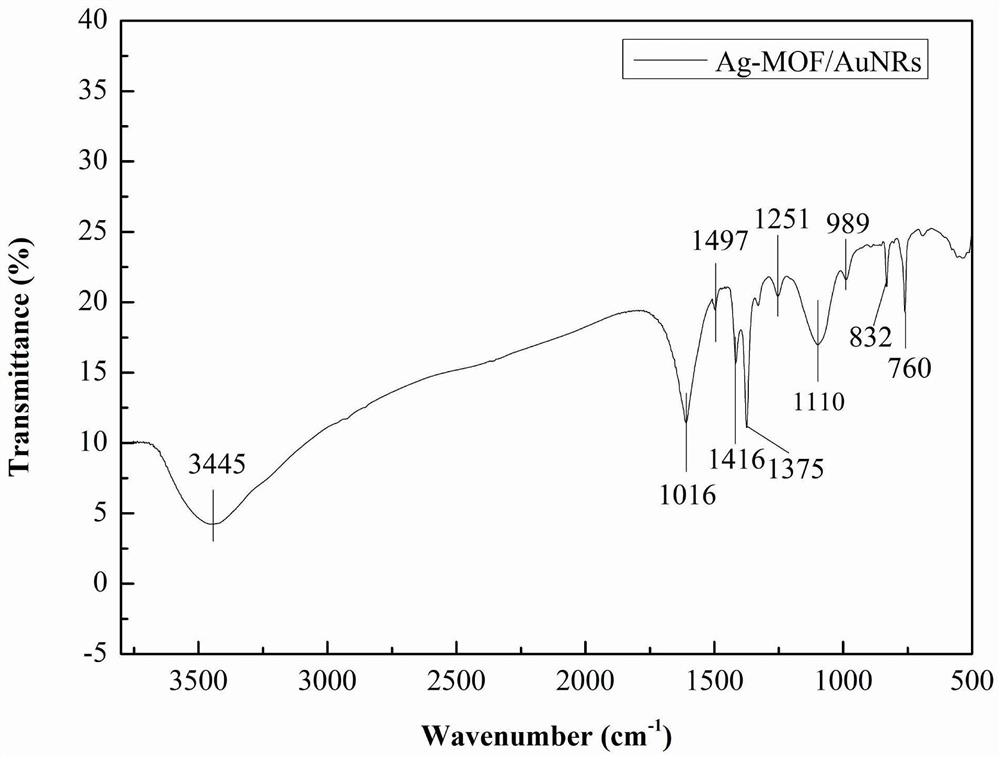

[0035] The synthesized materials were tested by infrared, respectively as figure 1 shown. figure 1 Shown in, 3445cm -1 The characteristic peak at represents the stretching of O-H, 1610cm -1 The characteristic peak at represents the stretching of N-H, 1416cm -1 The characteristic peak at represents the stretching of C=O, 1375cm -1 The characteristic peak at represents the stretching of C=C, 1251cm -1 The characteristic peak at represent...

Embodiment 2

[0037] An Ag-MOF / AuNRs nanocomposite material, the preparation method adopted is the same as that of Example 1 except that the silver source solution used is a silver nitrate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com