Temperature-resistant and salt-resistant silica gel fracturing fluid and preparation and application thereof

A technology of temperature resistance and salt resistance, fracturing fluid, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of long synthesis cycle, influence on viscosity increase performance, high cost, and achieve good temperature resistance and salt resistance. , the stability is easy to control, the effect of good viscosity increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

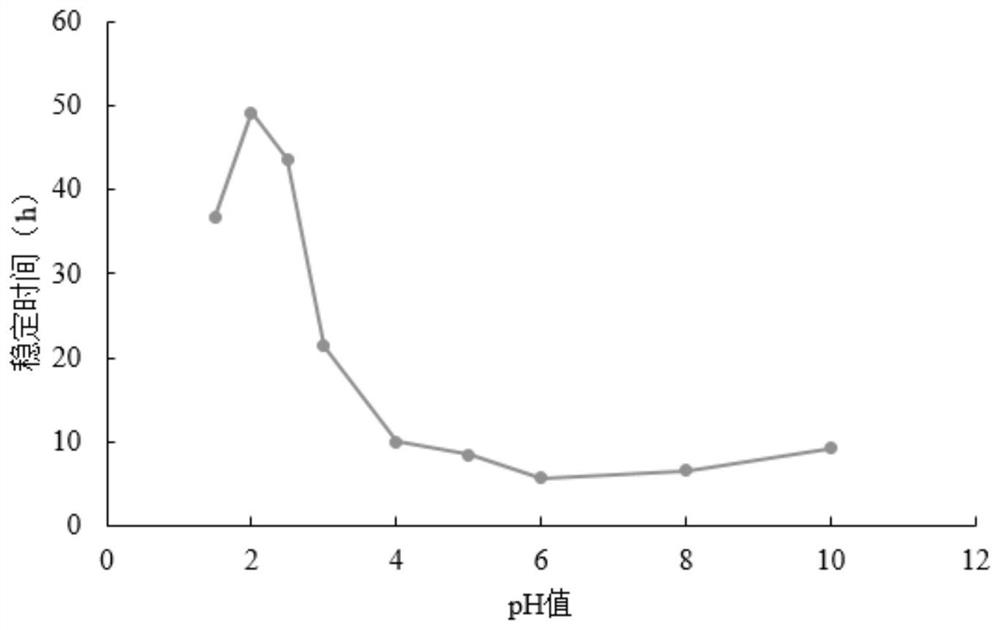

[0050] This embodiment provides the preparation method of acidic silica sol and investigates the influence of the pH value of acidic silica sol on its stability:

[0051] Wherein, the preparation method of described acidic silica sol comprises:

[0052] Weigh 5g of sodium silicate solid with a purity of 99.8% in the room and add it to a beaker filled with 95g of deionized water, and heat and stir in a water bath at 50-60°C until the sodium silicate solid is completely dissolved to obtain Sodium silicate aqueous solution with a viscosity of 4.5-5.5mPa·s, based on the total mass of sodium silicate aqueous solution as 100%, the mass concentration of silicon dioxide is 5% (ignoring 0.2% of other soluble substances and extremely A small amount of insoluble matter), the rest are alkali metal salts and deionized water;

[0053] Take another beaker, and dilute concentrated hydrochloric acid with a mass concentration of 37% according to the volume ratio of 100:85 to water into a dilut...

Embodiment 2

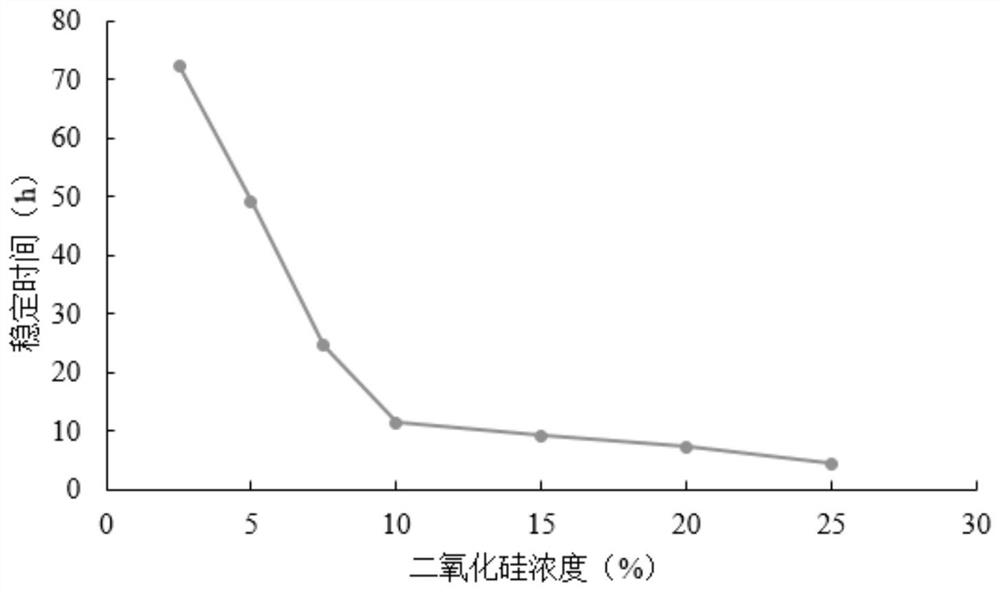

[0060] This embodiment provides the preparation method of acidic silica sol and investigates the influence of the mass concentration of silicon dioxide on its stability:

[0061] Wherein, the preparation method of described acidic silica sol comprises:

[0062] Weigh 2.5g, 5g, 7.5g, 10g, 15g, 20g, 25g of sodium silicate solids in the room and add them to 97.5g, 95g, 92.5g, 90g, 85g, 80g, 75g of deionized Put it in a beaker of water, and heat and stir in a water bath at 50-60°C until all the sodium silicate solids are dissolved to obtain an aqueous solution of sodium silicate with a viscosity distribution between 2.5-12mPa·s. The total mass of the aqueous solution of sodium silicate Calculated as 100%, the mass concentration of silicon dioxide is 2.5%, 5%, 7.5%, 10%, 15%, 20% and 25% respectively, and the rest is alkali metal salt and deionized water;

[0063] Then the above sodium silicate aqueous solution was added into dilute hydrochloric acid solution with a mass concentra...

Embodiment 3

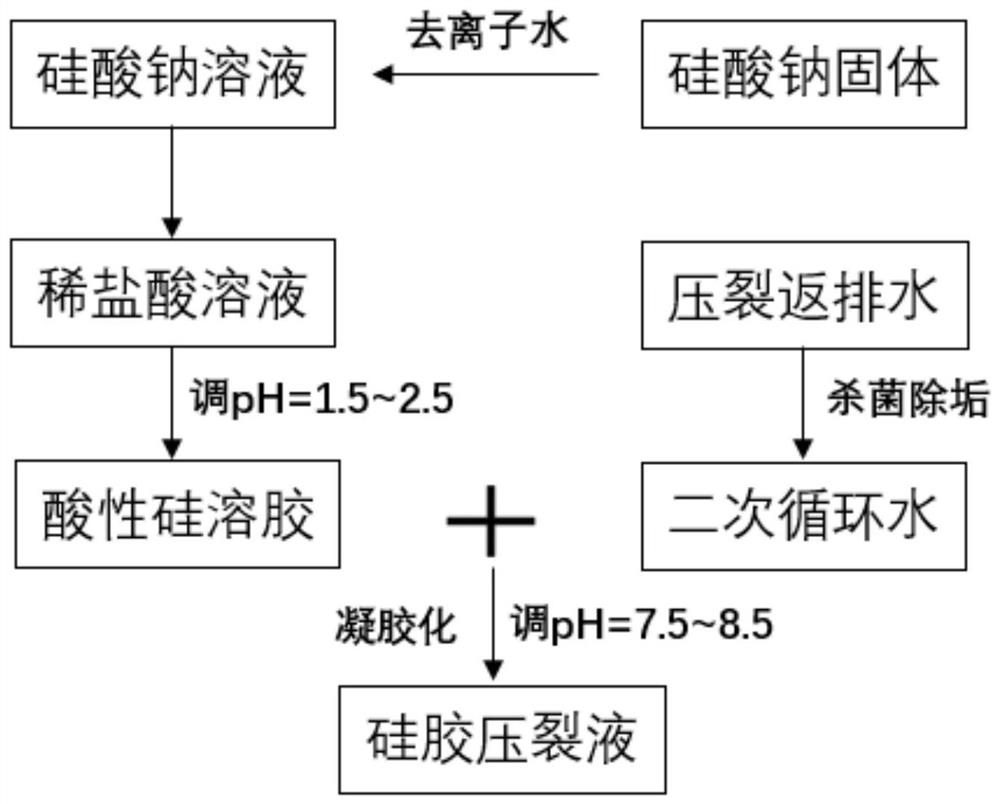

[0069] This example provides three kinds of temperature-resistant and salt-resistant silica gel fracturing fluid, and the flow chart of its preparation method is as follows figure 1 shown, from figure 1 It can be seen that the preparation method comprises the following specific steps:

[0070] Preparation of acidic silica sol:

[0071] Weigh 5g of sodium silicate solid in the room and add it into a beaker filled with 95g of deionized water, and heat and stir in a water bath at 50-60°C until all the sodium silicate solid dissolves to obtain a viscosity of 4.5- 5.5mPa·s sodium silicate aqueous solution, based on the total mass of sodium silicate aqueous solution as 100%, wherein the mass concentration of silicon dioxide is 5%, and the rest is alkali metal salt and deionized water;

[0072] Then the above-mentioned sodium silicate aqueous solution was added to the dilute hydrochloric acid solution with a mass concentration of 25% for mixing, so that the pH value of the formed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com