Self-cleaning type deoiling device for filtering oil-containing waste gas

A technology of deoiling device and exhaust gas filtration, which is applied in combination device, gas treatment, air quality improvement and other directions, can solve the problems of complex structure, waste of water, huge equipment, etc., to reduce secondary pollution, improve purification effect, and improve removal oil effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

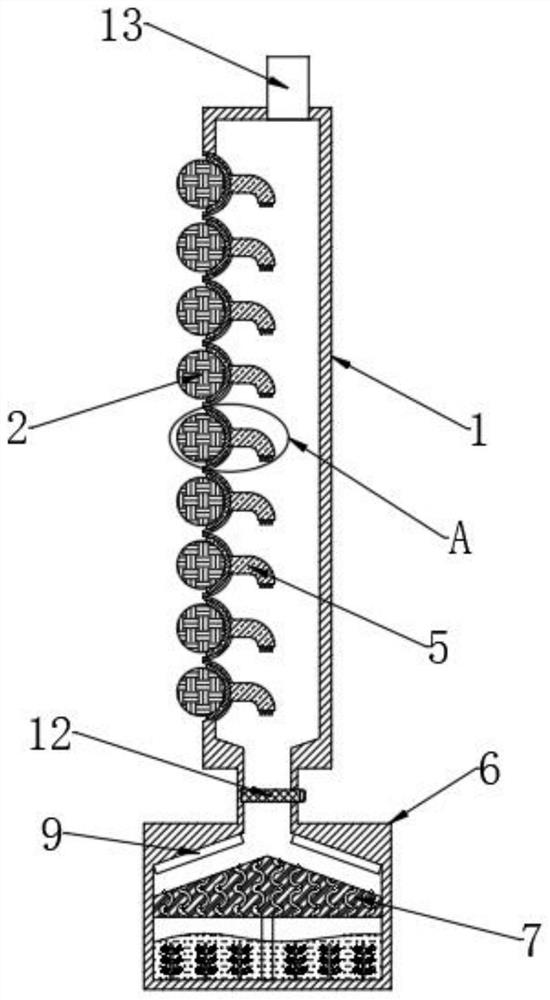

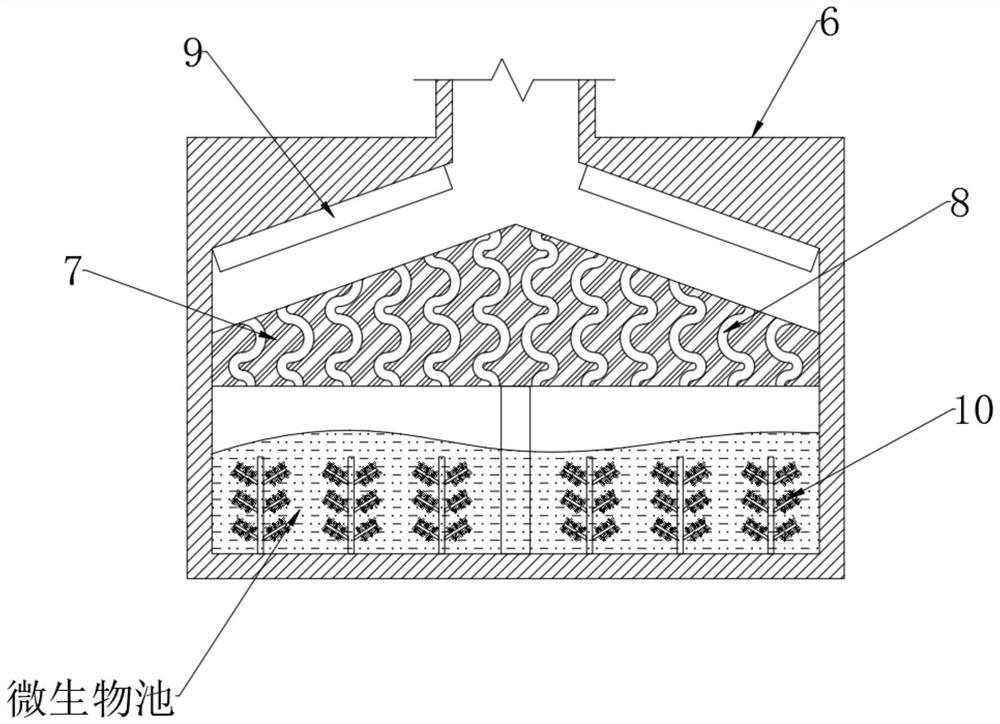

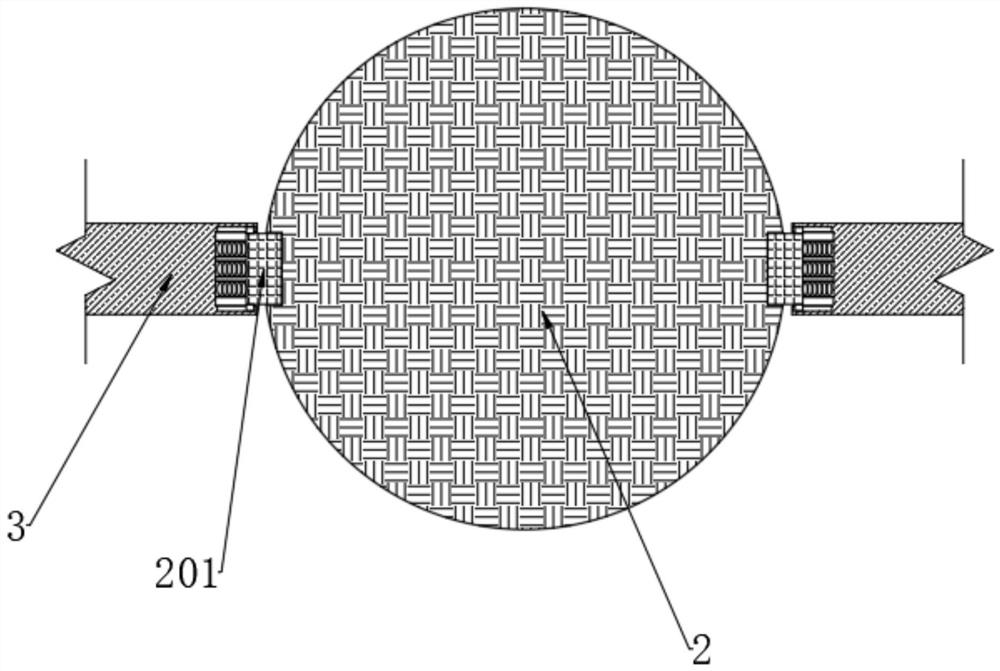

[0044] see Figure 1-7 , a self-cleaning deoiling device for oily waste gas filtration, including an electrostatic oil fume purification oil collecting plate body 1, please refer to figure 1 with Figure 7 , and the side wall of the electrostatic oil fume purification oil collection plate body 1 is rotatably connected with a plurality of evenly arranged oil collection balls 2, the upper end of the electrostatic oil fume purification oil collection plate body 1 is connected to the negative pressure air duct 13, and the electrostatic oil fume purification The oil collecting plate body 1 is a negative pressure environment, which is to allow the oil in the oil guide rod 5 to drip down smoothly, so as to prevent the oil absorbing plate 4 and the oil guide rod 5 from absorbing oil after being saturated. Please refer to Figure 3-4 , the inner wall of the electrostatic oil fume purification oil collecting plate body 1 is rotatably connected with a plurality of driving shafts 3, the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com