Photocatalysis system and application thereof

A catalytic system and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of difficulty in improving photosynthetic efficiency, separation and purification, etc., and achieve the effect of breaking through the kinetic speed bottleneck, reducing operating costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

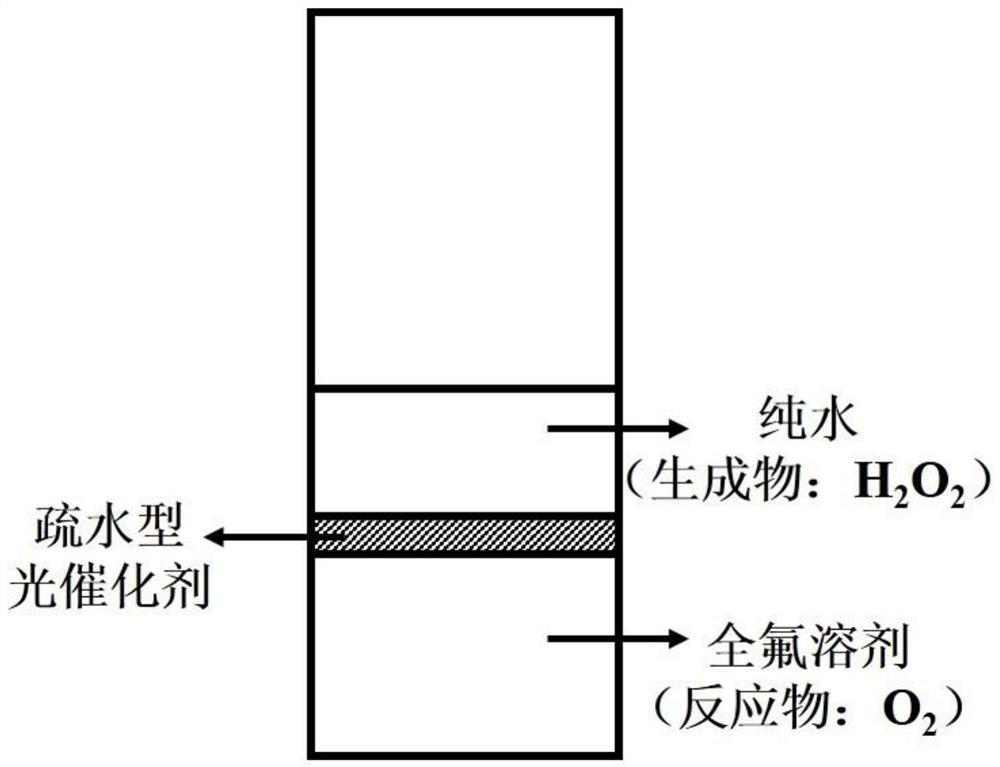

[0033] This embodiment provides a photocatalytic system and its 2 o 2 For applications in photosynthesis, please refer to the photocatalytic system figure 1 and Figure 6 ,specifically:

[0034] Add 2ml of perfluorooctane into the quartz reactor, expose it to oxygen until the concentration of dissolved oxygen reaches saturation, add a certain amount (1mg, 2mg, 4mg, 6mg) of hydrophobic photocatalyst Pd-A-BiVO 4 , and then add a certain volume (1ml, 2ml, 4ml, 6ml) of pure aqueous solution. The entire system controls the reaction temperature to 0°C through an ice-water bath, and under the action of magnetic stirring and LED light source, the photocatalytic production of H begins. 2 o 2 React, take a sample after reacting for 1h, determine the generated H by titanium salt photometry 2 o 2 concentration.

[0035] results and analysis:

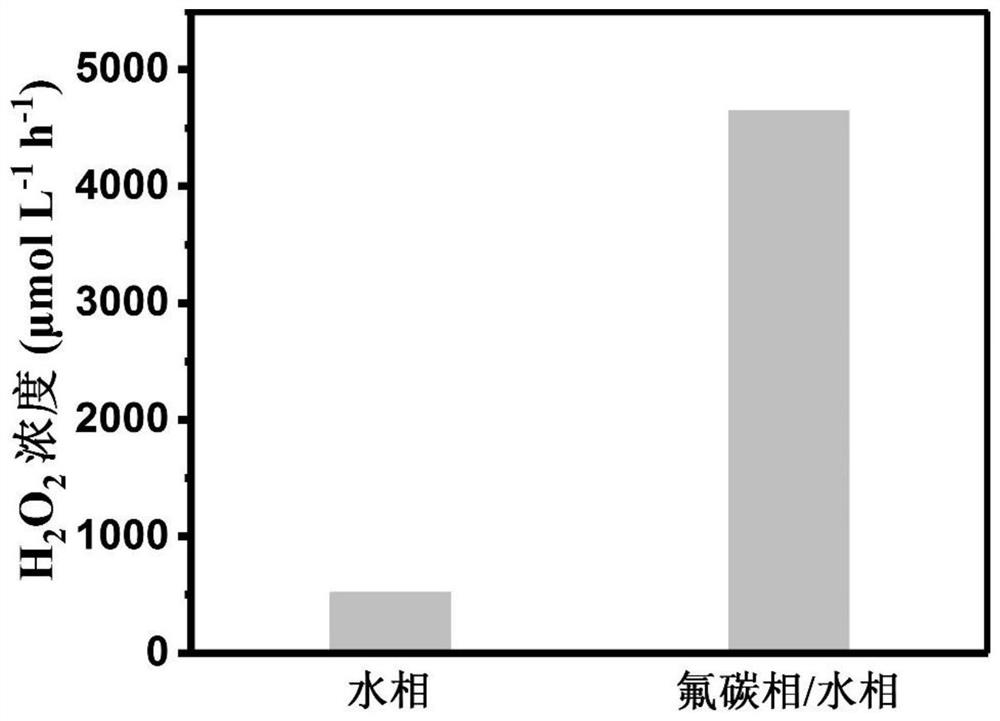

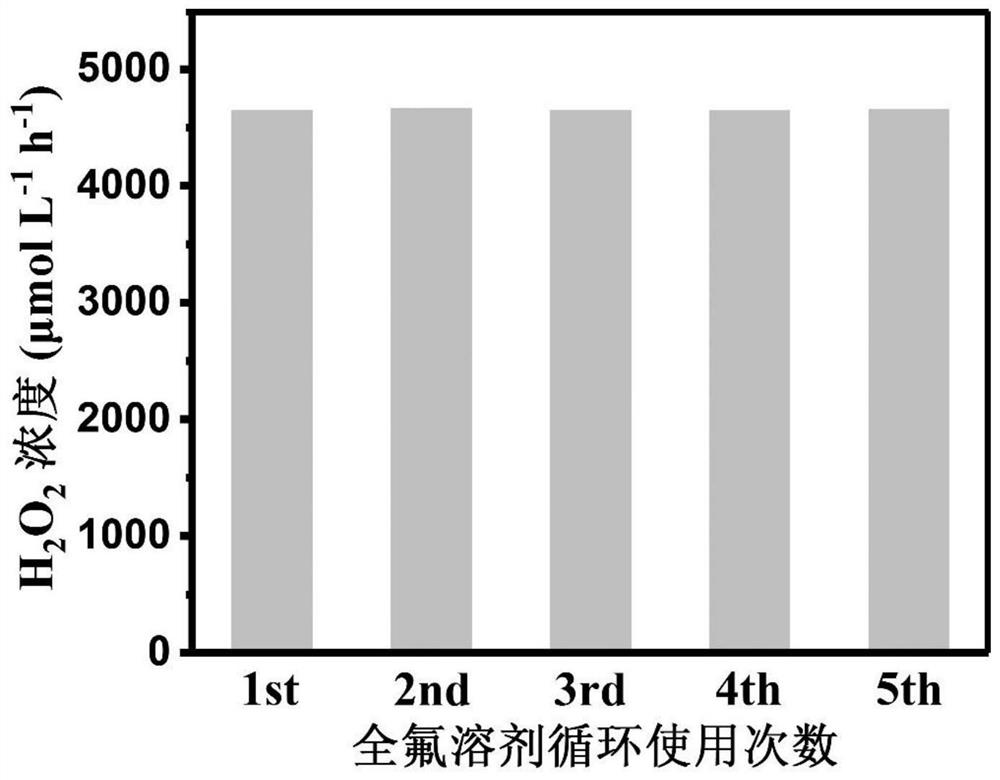

[0036] Analyze the results of the photocatalytic system provided in this example: the fluorocarbon phase / water phase system mentioned belo...

Embodiment 2

[0043] This embodiment provides a photocatalytic system and its 2 o 2 Applications in photosynthesis, specifically:

[0044] Add 4ml of perfluorohexane into the quartz reactor, expose it to oxygen until the dissolved oxygen concentration reaches saturation, add 4mg of hydrophobic photocatalyst COF A+C , and then add 2 ml of pure aqueous solution. The whole system controls the reaction temperature to 10°C through a water bath, and under the action of magnetic stirring and LED light source, the photocatalytic production of H begins. 2 o 2 React, take a sample after reacting for 1h, determine the generated H by titanium salt photometry 2 o 2 concentration.

[0045] The H obtained by reacting for 1h 2 o 2 The concentration is 12.1mM.

Embodiment 3

[0047] This embodiment provides a photocatalytic system and its 2 o 2 Applications in photosynthesis, specifically:

[0048] Add 5ml of perfluorodecalin into the quartz reactor, expose it to oxygen until the dissolved oxygen concentration reaches saturation, add 3mg of hydrophobic photocatalyst OPA / Zr 92.5 Ti 7.5 -MOF, and then add 5ml of pure aqueous solution. The whole system controls the reaction temperature to 25°C through a water bath, and under the action of magnetic stirring and LED light source, the photocatalytic production of H begins. 2 o 2 React, take a sample after reacting for 1h, determine the generated H by titanium salt photometry 2 o 2 concentration.

[0049] The H obtained by reacting for 1h 2 o 2 The concentration is 5.5mM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com