A method for detecting nitrosamine impurities in biapenem

A technology of nitrosamines and detection methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of high detection sensitivity and achieve the effects of reducing influence, reducing matrix effect, and avoiding inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Liquid chromatography conditions: Chromatographic column: Waters ACQUITY UPLC HSS T3 column (1.8μm, 2.1mm×100mm); mobile phase A: 0.1% formic acid-water, mobile phase B: methanol; column temperature 40 ℃; flow rate 0.3ml / min;

[0043] The elution program is: 0~3min, A 95%, B 5%; 3.5~4.5min, A 90%, B 10%; 5.5~6.5min, A60%, B40%; 7~8min, A 20%, B 80%; 8.1~9.5min, A 0%, B 100%; 9.6~12min, A 95%, B 5%.

[0044] 2. Mass spectrometry conditions: ion source APCI source, scan mode MRM, ion pair: N-nitrosoethylisopropylamine (EIPNA) 117.1 / 75.1, collision energy 15V; N-nitrosodiisopropylamine (DIPNA) 131.1 / 89.1, collision energy 15V; N-nitrosodiethylamine (NDEA) 103.1 / 47.0, collision energy 29V; internal standard NDEA-d4 107.0 / 77.0, collision energy 16V; internal standard NDPA-d14 145.0 / 50.0, collision Can be 19V.

[0045] 3. Mixed solvent preparation: Take 20ml of methanol and put it in a reagent bottle, add 170ml of water, then add 10ml of formic acid, and shake well. ...

Embodiment 2

[0052] With reference to the detection method of embodiment 1, detection result is as follows:

[0053] 1. Exclusiveness

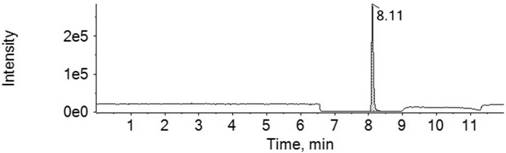

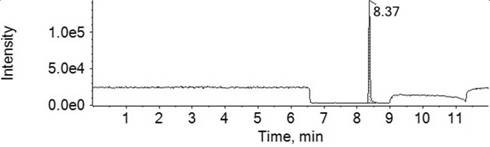

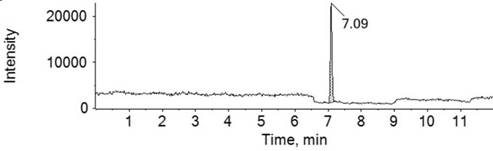

[0054] The reference substance solution and the spiked solution with a concentration of 1.319 ng / ml were taken respectively for sample testing, and the recorded chromatograms are shown in Figure 1~6 shown. The figure shows that the peak position of the target peak in the 100% limit concentration spiked test solution has no interference from other impurities, and is similar to the peak shape of the 100% limit concentration reference solution, indicating that the detection method has good specificity.

[0055] 2. Linear

[0056] The standard curve solution was taken for sample loading test, and the linear fitting equation was obtained through the relationship between peak area and concentration, as shown in Table 1 below. For each impurity in each concentration range, the peak area ratio has a good linear relationship with the concentration, and the correl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com