Adsorption structure of high-capacity battery

An adsorption structure and large-capacity technology, which is applied to structural parts, battery pack parts, secondary battery gas removal, etc., can solve the problems of low effect, high cost, and high equipment integration, so as to reduce the risk of fire and improve Adsorption efficiency, the effect of delaying the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present application will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0021] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

[0022] The technical solutions of the embodiments of the present application will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

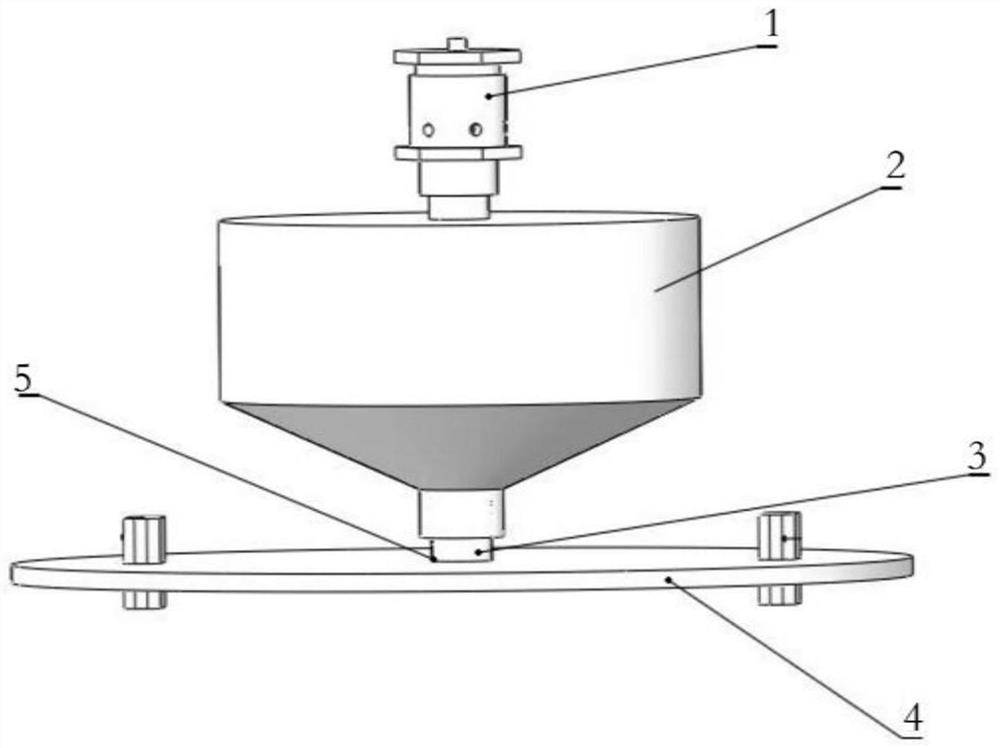

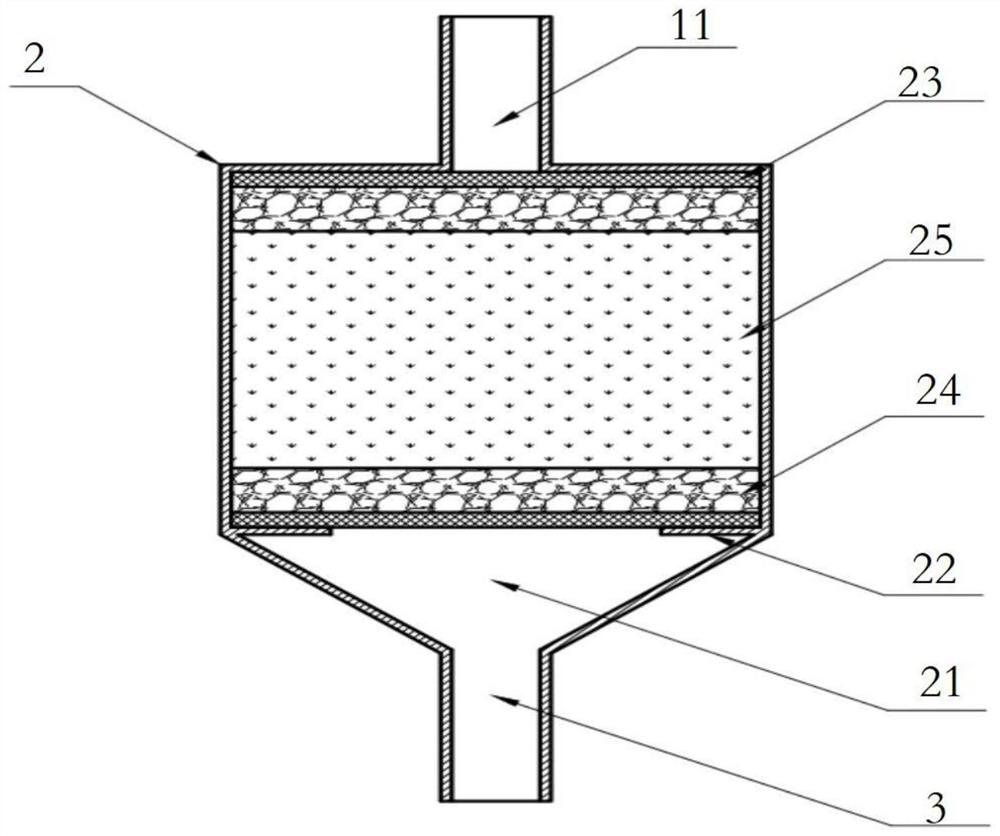

[0023] Such as figure 1 , 2 As shown, the application provides an adsorption structure for a large-capacity battery, including an adsorption chamber 2 connected to the battery (the battery is not completely drawn, only a cover plate with an explosion vent) 4, and the adsorption chamber 2 A one-way pressure relief valve 1 connected to the upper end; wherein, the one-way pressure relief valve 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap