Two-spraying and one-curing equipment and process for corrosion-resistant workpiece adopting composite coating

A technology for composite coatings and workpieces, which is applied to coatings, devices for coating liquid on surfaces, and spray booths. Large difference in anti-corrosion ability, less polluting exhaust emissions, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

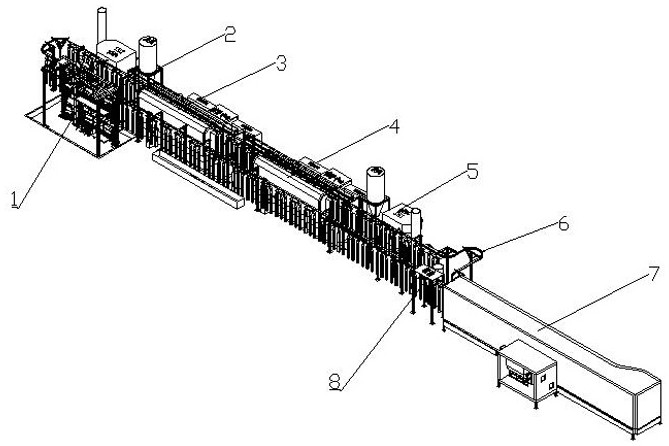

[0042] Example 1 A kind of two-spray and one-fix equipment that adopts composite coating anticorrosion workpiece

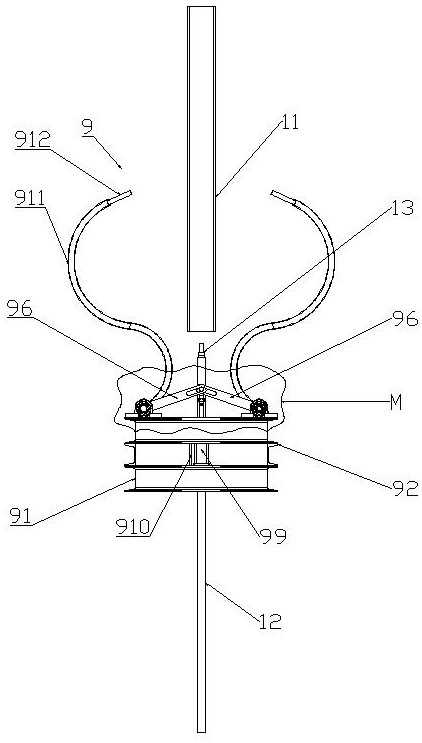

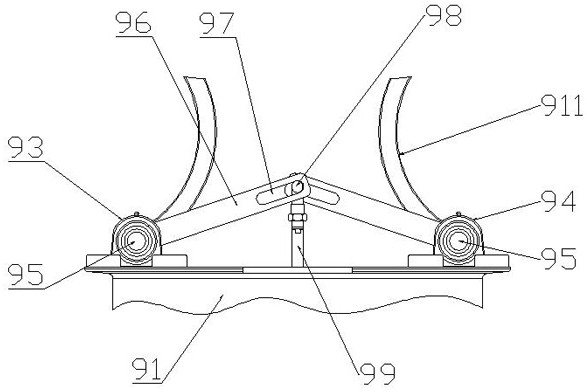

[0043] like Figure 1-Figure 6 Commonly shown, the present invention provides a kind of two-spray-one-solid equipment that adopts composite coating anticorrosion workpiece, comprises shot blasting derusting device 1, primary spraying recovery device 2, primary spraying system 3, secondary spraying system 4, secondary spraying Recovery device 5, catenary conveying system 6, curing furnace device 7, catenary drive and whole line control system 8.

[0044]The catenary conveying system 6 includes a catenary 61 , the bottom of which is connected to a catenary trolley 63 through a suspension rod 62 ; the bottom of the catenary trolley 63 is provided with a plurality of hooks 64 for hanging the column workpiece 11 . The catenary conveying system 6 is used for hanging and conveying the column workpiece 11. During the conveying process, shot blasting, primary spraying, se...

Embodiment 2

[0061] Embodiment 2 A kind of two-spray-one-solid process that adopts composite coating anticorrosion workpiece

[0062] like Figure 1-Figure 6 As shown together, the present invention provides a two-spray-one-cure process using a composite coating for anti-corrosion workpieces, including the steps of shot blasting and derusting treatment, primary spraying treatment, secondary spraying treatment and joint curing.

[0063] Among them, the shot blasting and derusting treatment is used to degrease and derust the surface of the suspended column workpiece, and the quality of the anchor pattern on the surface is required to reach Sa2.5 level.

[0064] Among them, the first spraying treatment is used to complete the electrostatic spraying of epoxy zinc-rich primer, and the second spraying treatment is used to complete the electrostatic spraying of polyester flour.

[0065] In both the primary spraying process and the secondary spraying process, the uprighting process is carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com