Automatic weighing and packaging equipment for precious metal particles and weighing method of automatic weighing and packaging equipment

A technology of automatic weighing and packaging equipment, applied in the direction of automatic feeding/discharging of weighing equipment, packaging, wrapping paper, etc., can solve the problems of inaccuracy, manual contact, and easy contamination of precious metal particles with actual weight, etc. Achieve the effect of ensuring accuracy, high degree of automation, and eliminating weight inconsistencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in more detail below in conjunction with examples.

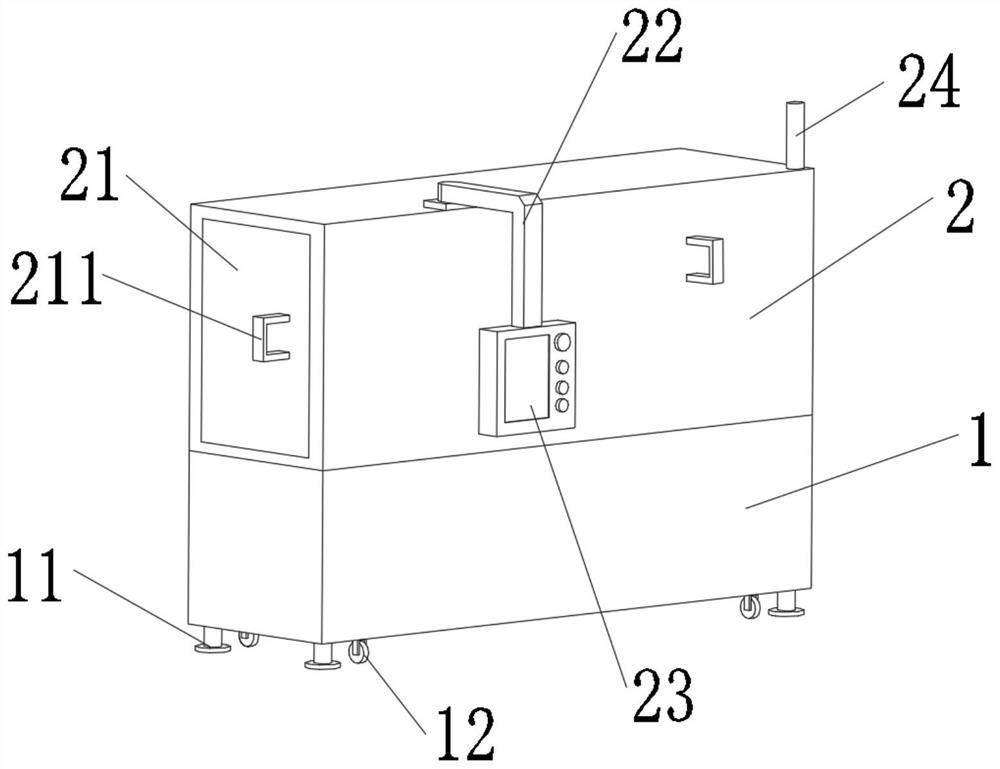

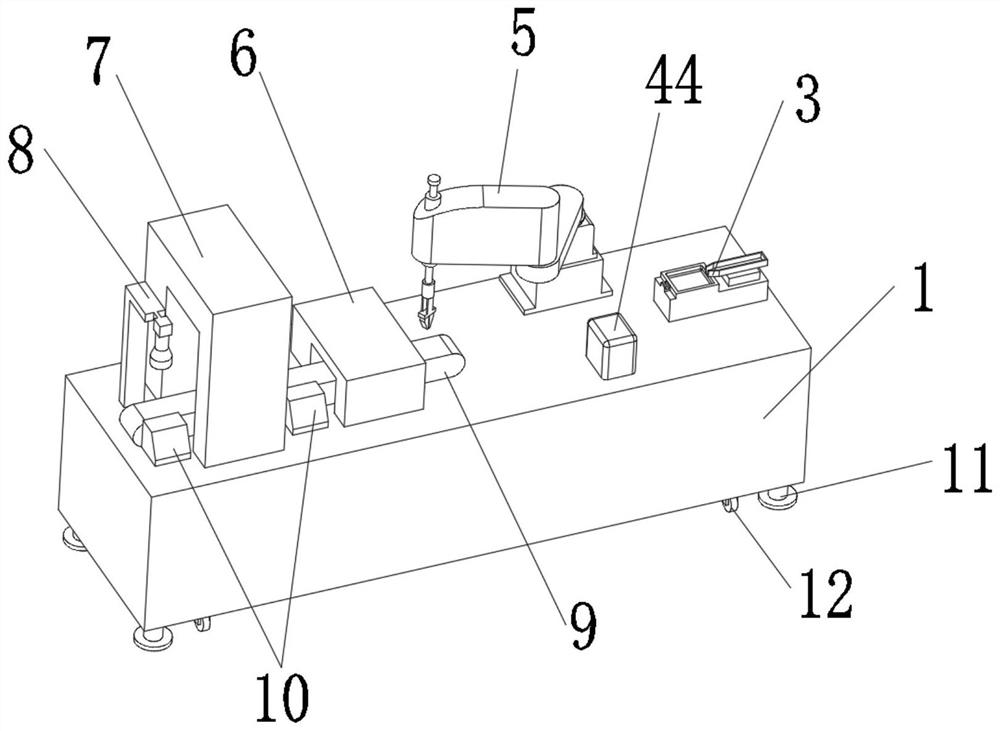

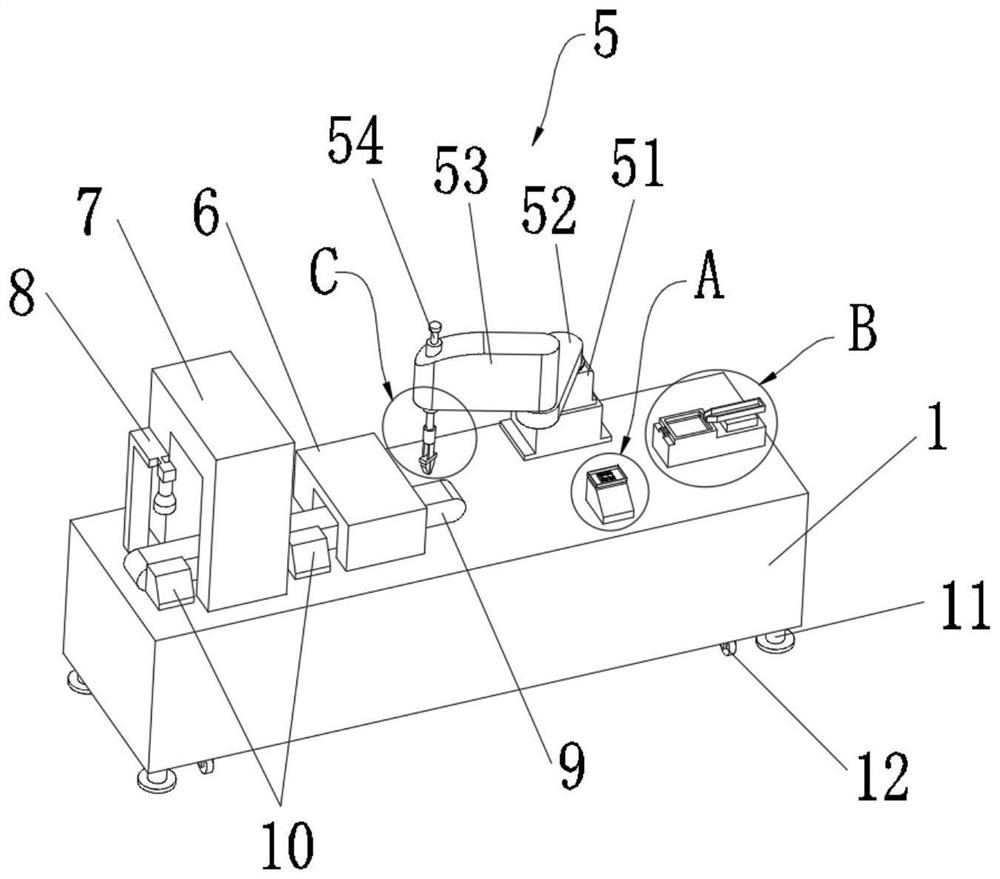

[0044] Such as Figures 1 to 7 As shown, the automatic weighing and packaging equipment for precious metal particles in this embodiment, taking weighing gold particles as an example, includes a support part 1, and an isolation cover 2 is arranged on the upper end of the support part 1, and the isolation cover 2 isolates external interference, so that the gold particles Weigh as far as possible without interference to ensure accuracy; four foot cups 11 and four universal wheels 12 are provided at the bottom of the support part 1 to facilitate movement and support; Transparent protective door 21, wherein two relative protective doors 21 along the length direction are respectively used as input end and output end, transparent protective door 21 can observe the working situation inside isolation cover 2 conveniently, and protective door 21 is provided with door handle 211 A feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com