Excited clay brick micro-powder, preparation method thereof, cementing material and regenerated brick

A technology for cementitious materials and clay bricks, which is applied in the field of construction waste treatment, can solve the problems of anti-alkali in bricklaying, reduce bricklaying strength, and low compressive strength of clay bricks, achieve efficient recycling, ensure application quality, and enhance water effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present application will be further described in conjunction with preparation examples, comparative examples, and application examples.

[0029] raw material Manufacturer cement Tangshan Hongqi Cement Co., Ltd. Diethanol monopropanolamine Jiang Yincheng Forest Chemical Co., Ltd. Triopropanolamine Henan Zhenhang Chemical Products Co., Ltd.

[0030] Preparation method of exciting clay brick micropowder includes the following steps:

[0031] Physics excitation: Take the construction waste clam tile, ground the spherical grinding and cement grinding to ground the fineness of 0.045mm-0.06mm;

[0032] Chemical excitation: Add to the construction waste clastic brick micropowder to the lyncolamola amlamine osmestant in the weigh 0.01-0.06% of the construction waste classes; mixing to excite clay brick micropowder.

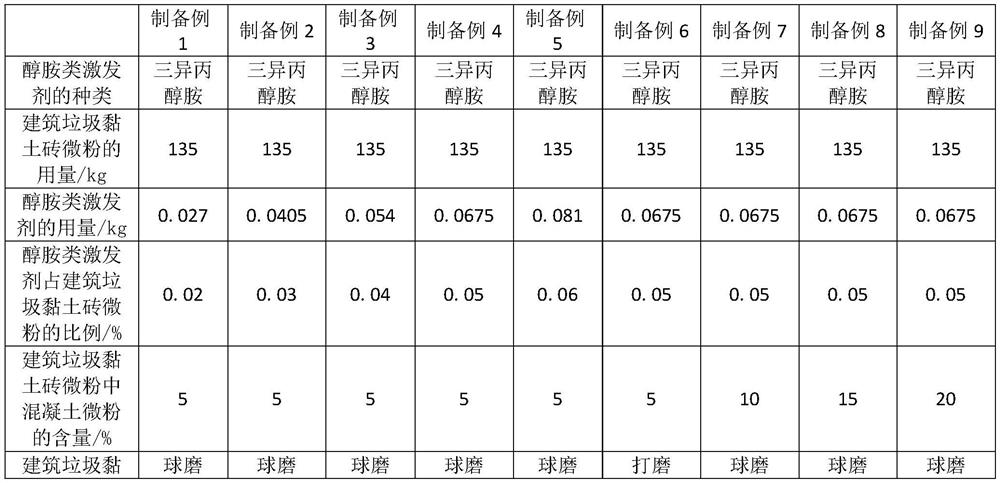

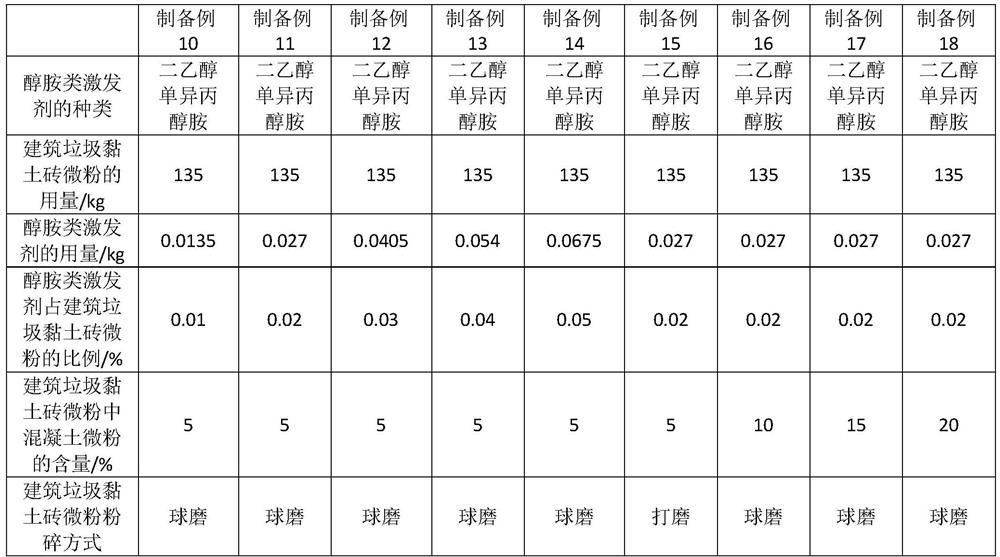

[0033] Table 2 Preparation Example 1-9 provides a raw material ratio and preparation conditions for exciting clay brick micropowder

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com