Method for improving production capacity of amino acid producing strain

A production capacity, amino acid technology, applied in the field of genetic engineering, can solve the problems of long process lines, high cost, difficult to put into production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

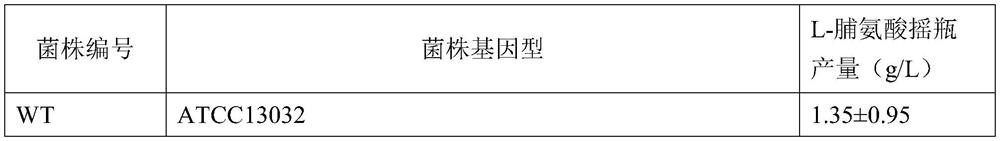

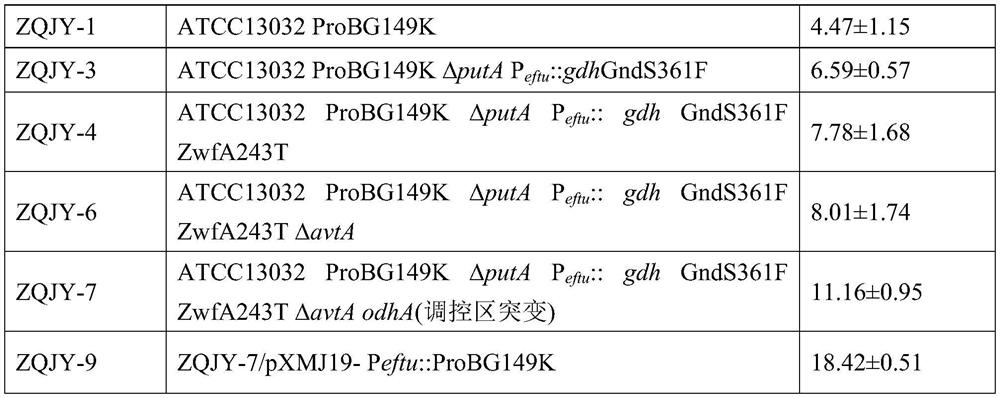

[0097] Example 1: Construction of gene putA, gnd mutation and gene gdh enhanced bacterial strain ZQJY-3

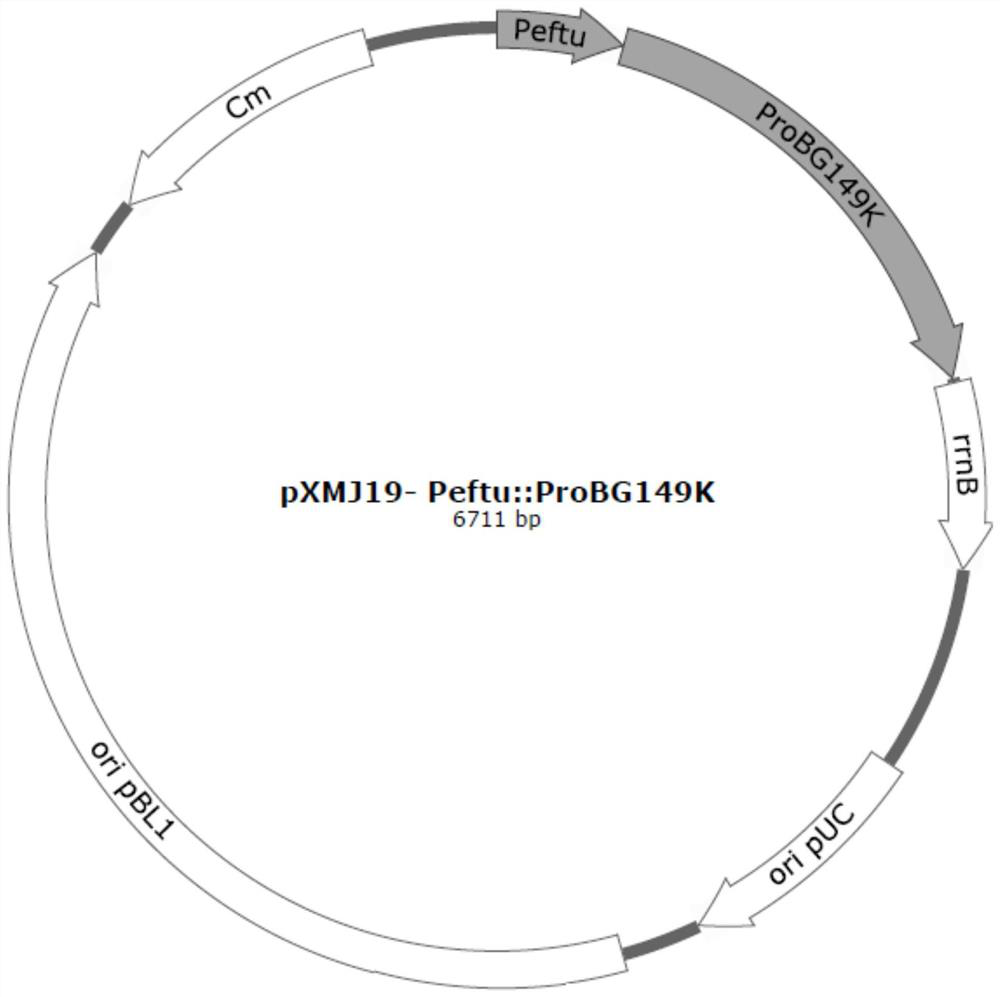

[0098] 1. Construction of pk18mobsacB-spec-Peftu-gdh plasmid

[0099] (1) Using primers pk18-kan-zzz-F and pk18-EcoRI-R, using pk18mobsacB as a template, amplify fragment 1 of about 4.3 kb, using primers pk18-crtYf-L and pk18-crtYf-R, using the literature ( The plasmid pJYS3_ΔcrtYf reported in Jiang, Y., et al., Nature Communications, 2017.8) was used as a template to amplify fragment 2 of about 2.1 kb, using primers pk18-HindIII-F and pk18-kan-qdz-R, using pk18mobsacB as a template , to amplify fragment 3 of about 500bp, and use primers pk18-spec-F and pk18-spec-R to amplify about 1.2 Kb spectacle-resistant fragment 4, fragments 1, 2, 3, and 4 were connected by Gibson, transformed into E. coli DH5α competent cells (Shanghai Donghuan Biotechnology Co., Ltd.), and coated with LB-spec plates to obtain plasmid pk18mobsacB-spec_ΔcrtYf .

[0100] (2) Use primers pk18-HindIII...

Embodiment 2

[0114] Embodiment 2: construct the bacterial strain ZQJY-4 of gene zwf inactivation

[0115] 1. Construction of inactivated plasmid pK18mobsacB-ZwfA243T

[0116] Using primers pk18-F and pk18-R, using pK18mobsacB as a template, amplified about 5.6kb vector fragment 11, using primers zwf-aL-F / zwf-aL-R and primers zwf-aR-F / zwf-aR- R used the ATCC 13032 genome as a template to amplify fragments 12 and 13 of about 1 kb, perform Gibson ligation of fragments 11, 12, and 13, and transform DH5α competent cells to obtain plasmid pK18mobsacB-ZwfA243T.

[0117] 2. Prepare ZQJY-3 competent cells.

[0118] The preparation method is the same as step 2 of Example 1.

[0119] 3. Transform plasmid pK18mobsacB-ZwfA243T into ZQJY-3 competent cells

[0120] The conversion method is the same as step 3 of Example 1. After recovery, all the bacteria were spread on the BHIS plate containing kanamycin, and the plate was inverted and cultured in a constant temperature incubator at 30°C for 48 hours...

Embodiment 3

[0123] Example 3: Construction of the bacterial strain ZQJY-6 inactivated by the gene avtA

[0124] 1. Construction of plasmid pJYS2_avtA

[0125] Using primers avtAspc-F and avtAspc-R to amplify the fragment with pJYS2_crtYf as a template, directly transform DH5α competent cells, and coat BHIS solid plates containing spectinomycin to obtain plasmid pJYS2_avtA.

[0126] 2. Synthetic repair template avtA(TAA)59

[0127] The repair template avtA(TAA)59 sequence is:

[0128] CAGAGATCGCTCTTCGCTCGGGTCCTTAATAATACACCGAGGTGATTGGTGATCGTGAG

[0129] 3. Prepare ZQJY-4 competent cells.

[0130] The preparation method is the same as step 2 of Example 1.

[0131] 4. Transform plasmid pJYS2_avtA and repair template avtA(TAA)59 to ZQJY-4 competent cells

[0132] Take 1 μg of the above-mentioned plasmid pJYS2_avtA and 1-10 μg of the repair template avtA(TAA)59, mix them and add them to the competent cells of Corynebacterium glutamicum ZQJY-4, and transfer them to the electroporation cup a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com