Genetically engineered bacterium for producing 4-hydroxyisoleucine and application of genetically engineered bacterium

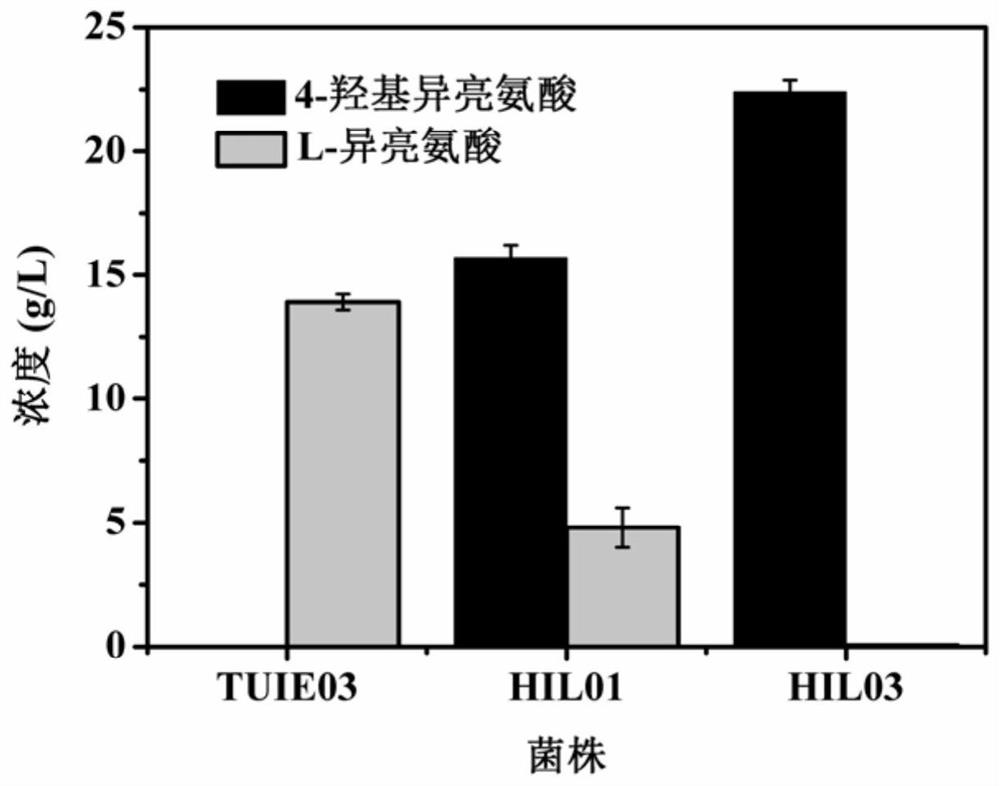

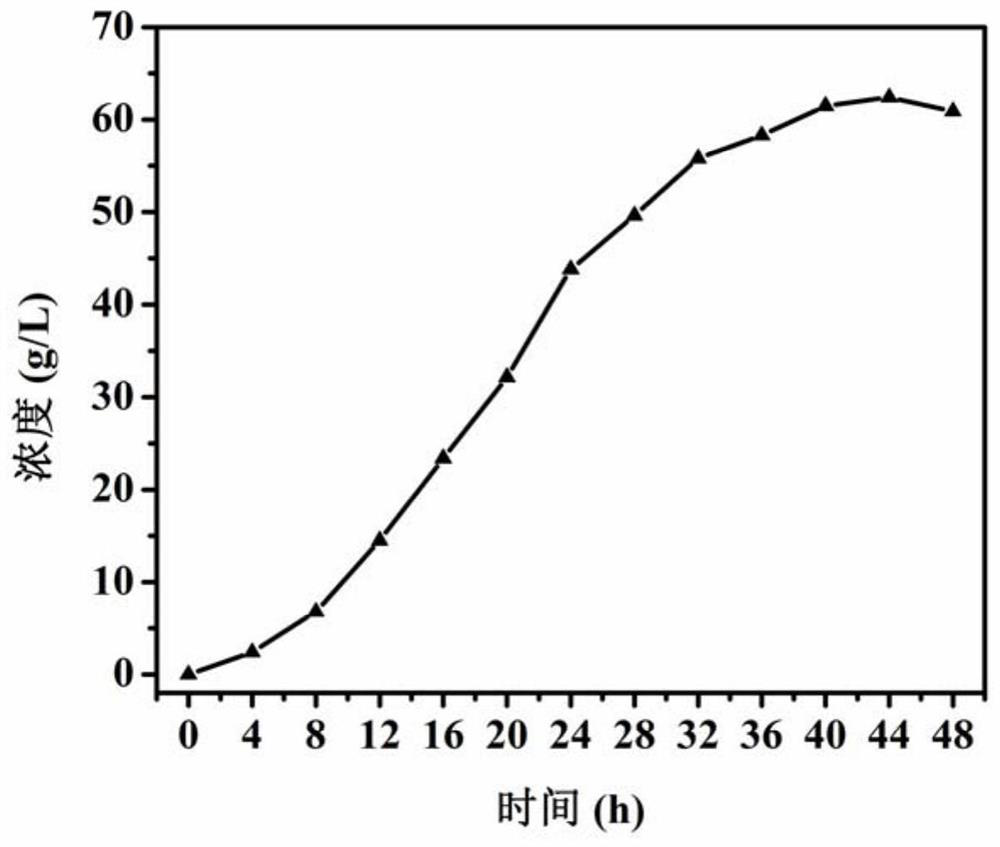

A technology of hydroxyisoleucine and isoleucine, which is applied in the field of metabolic engineering, can solve the problems of long fermentation period, low yield of 4-hydroxyisoleucine and high production cost, and achieves low production cost, easy control, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Construction of 4-hydroxyisoleucine synthesis pathway in TUIE03

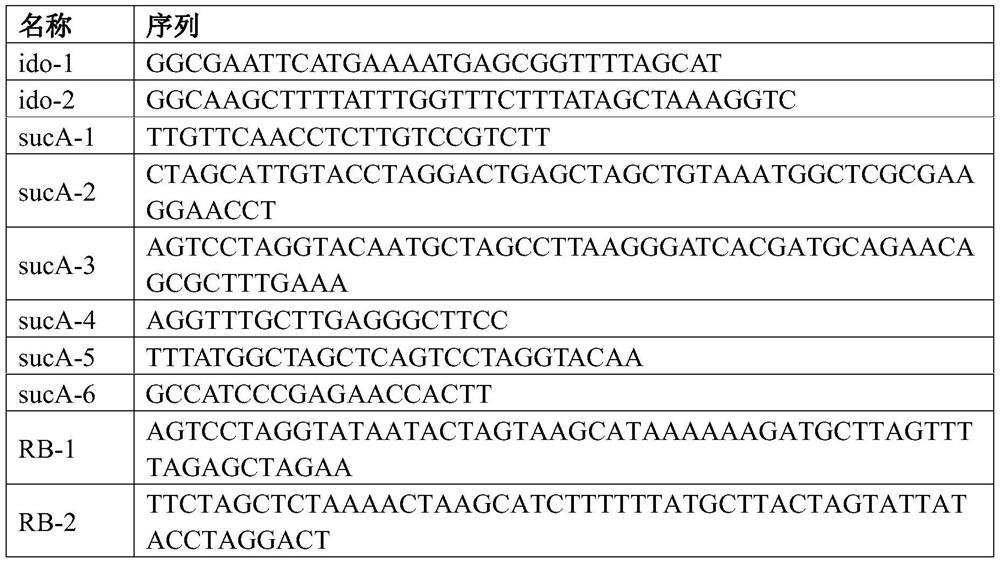

[0033] (1) amplification of ido gene and

[0034] Using the ido gene fragment shown in SEQ ID NO.1 as a template, primers ido-1 and ido-2 were designed to amplify the ido gene fragment, and the PCR product was subjected to agarose gel electrophoresis and recovered with a gel recovery kit.

[0035] (2) The construction of recombinant plasmid pSTV28-ido is

[0036] Plasmid pSTV28 and gene fragment ido were digested with restriction endonucleases EcoR I and Hind III respectively. Then, the linearized pSTV28 plasmid and ido fragment were recovered and purified using a gel recovery kit, and ligated with T4 ligase. The ligation product was transformed into E.coli DH5α competent cells, evenly spread on the LB solid medium plate containing 0.05mmol / L chloramphenicol after recovery, and cultured overnight at 37°C. The next day, a single colony on the plate was selected for colony PCR verification using...

Embodiment 2

[0039] Example 2: Construction of sucA weakened bacteria HIL02

[0040] (1) Construction of overlapping fragments

[0041] Using the Escherichia coli W3110 genome as a template, primers sucA-1 / sucA-2 and sucA-3 / sucA-4 were used to amplify the upstream and downstream homology arms of the sucA promoter, in which the primers contained the weak promoter BBA_J23114 sequence, and the PCR product After recovery, the fusion fragment U comprising the upper and lower homology arms of the sucA promoter and the promoter BBA_J23114 was obtained by overlapping PCR PsucA -BBA_J23114-D PsucA .

[0042] (2) Construction of pGRB-sucA plasmid

[0043] Design and synthesize gRNA 20bp forward and reverse sequences RB-1 and RB-2 according to the sucA promoter sequence. After annealing, the two are connected to the plasmid using the recombination kit ClonExpress II One Step Cloning Kit (Nanjing Nuoweizan Medical Technology Co., Ltd.) pGRB, the recombinant plasmid pGRB-sucA was obtained by transf...

Embodiment 3

[0046] Embodiment 3: Construction of 4-hydroxyisoleucine producing bacteria HIL03

[0047] The recombinant plasmid pSTV28-ido was extracted and transformed into strain HIL02 by electrotransformation. The strain HIL03 was obtained by chloramphenicol resistance plate screening and colony PCR identification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com