Resistance paste for high-stability thick-film resistor

A technology of resistance paste and thick film resistors, which is applied in thick film resistors, resistors, resistor manufacturing, etc., can solve the problems of low power resistance, low technical performance and reliability of resistance paste, and achieve improved thermal conductivity, The effect of high resistance stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

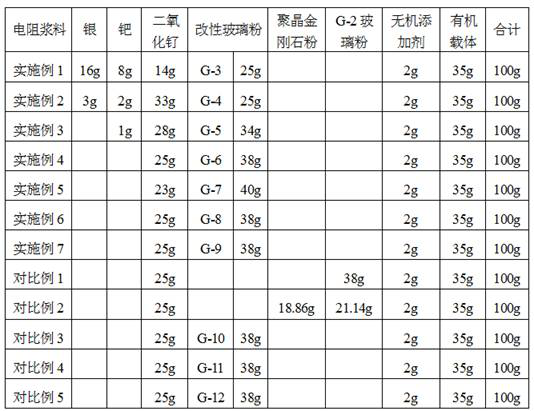

Examples

Embodiment

[0017] Preparation of glass powder: according to the mass percentage, the composition is PbO 44%, Al 2 o 3 19%, B 2 o 3 15%, SiO 2 22% to prepare glass powder G-1, composed of PbO 60%, SiO 2 17%, B 2 o 3 12%, Al 2 o 3 11% to prepare glass powder G-2. The specific preparation method is: after mixing various oxides evenly, put them in a melting furnace at 1400 ° C for 1.5 hours, and the obtained glass solution is water-quenched and broken into glass slag, and the glass The slag is ground into a particle size of 1.0-1.3 μm by a ball mill, and dried to obtain glass powder G-1 and G-2.

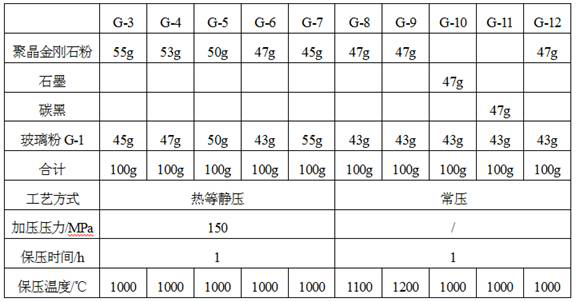

[0018] Preparation of modified glass powder: select polycrystalline diamond powder with a particle size of 1-5 μm prepared by carbon black through directional blasting method, mix uniformly with glass powder G-1 according to the ratio in Table 1, and granulate, then heat In the isostatic pressing process, pressurize and hold at 150MPa and different temperatures for 1h, or at normal pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com