Mold material composition and method for manufacturing mold using same

A material composition and manufacturing method technology, applied in the directions of casting molds, casting mold components, manufacturing tools, etc., can solve problems such as difficulty in regeneration, high efficiency, and difficulty in removing water glass, and achieve inhibition of re-welding, dissolution, and disintegration. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

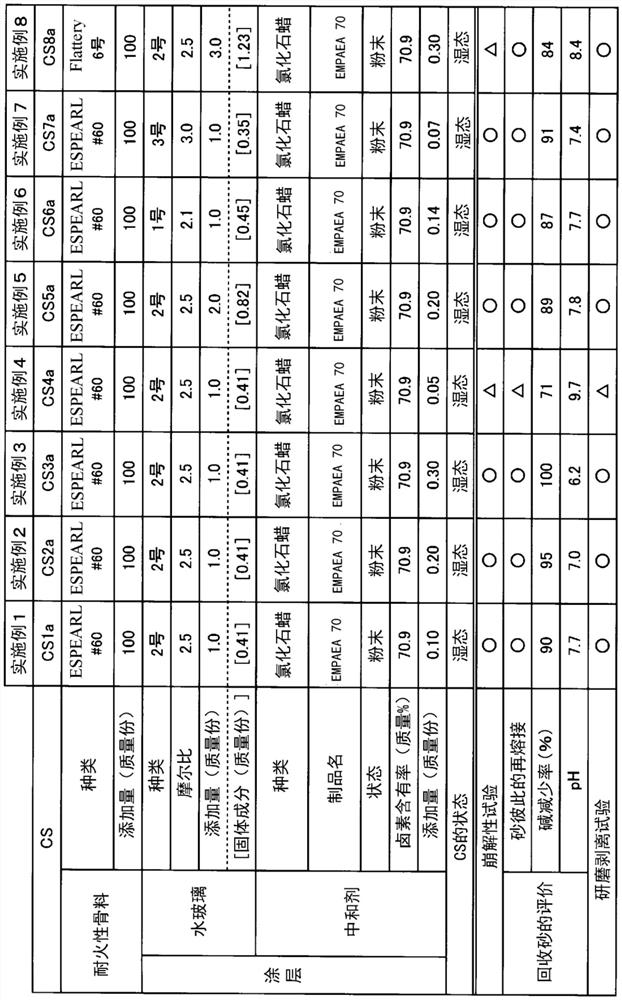

[0108] Hereinafter, the present invention will be described in more detail using some examples of the present invention, but it should be understood that the present invention is not subject to any limited interpretation due to the description of such examples. In addition, in the following examples and comparative examples, unless otherwise specified, "%" and "part" are expressed on a mass basis. In addition, the disintegration test of the mold obtained by using each mold material composition (coated sand: CS) of the example and the comparative example, the evaluation of the recovered refractory aggregate (recovered sand), and the alkali reduction rate The calculation of pH, the measurement of pH, and the grinding peeling test were respectively performed as follows.

[0109] -Disintegration test of mold-

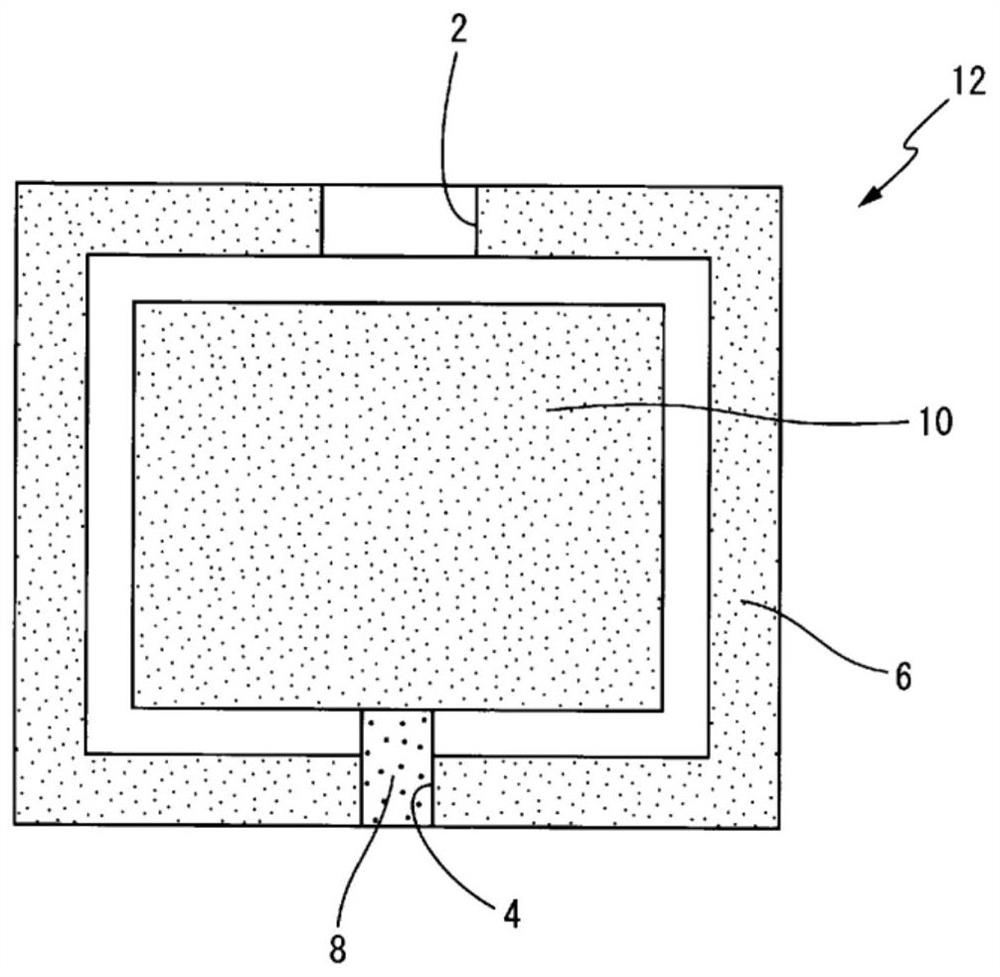

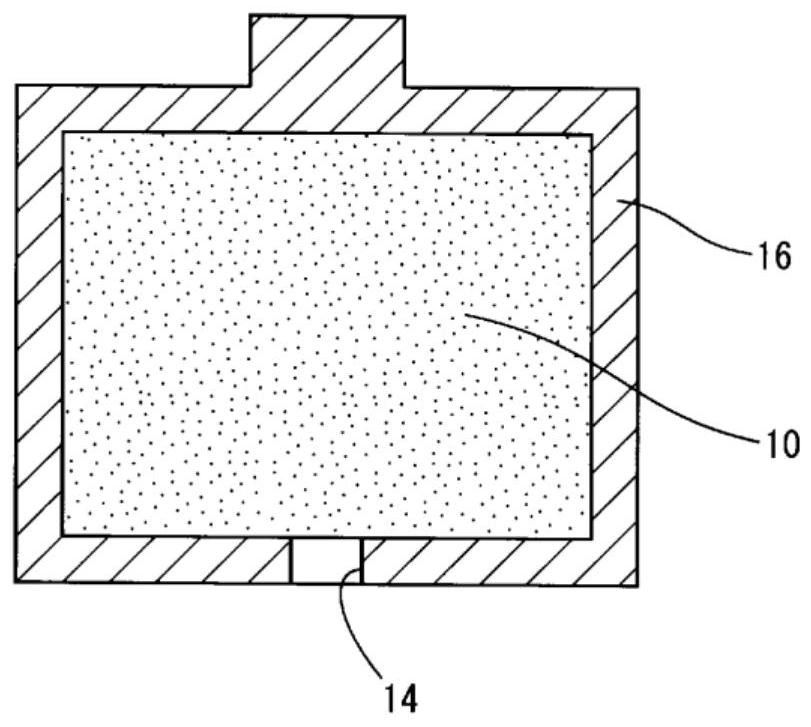

[0110] First, if figure 1 As shown, the half-division of the core seat fixing part 4 (this part is the discharge port for discharging the waste core from the casting) mad...

manufacture example 1

[0155] Using water glass (No. 2 sodium silicate), a water glass aqueous solution having a solid content (concentration) of 41% was prepared. Put the refractory aggregate (ESPEARL#60) into the Shinagawa-type universal mixer (5DM-r type, manufactured by DALTON CORPORATION) at room temperature, and add the above-mentioned water glass aqueous solution at a ratio of 1.0 part to 100 parts of the refractory aggregate , and add chlorinated paraffin (EMPARA 70) as a neutralizing agent at a ratio of 0.10 parts to 100 parts of refractory aggregates, knead for 3 minutes, stir and mix until it becomes uniform, then take it out, thus obtaining A wet-state casting material composition (wet-state CS: CS1a) in which a coating layer containing water glass and a neutralizer (chlorinated paraffin) is provided on the surface of the refractory aggregate.

[0156] -Production examples 2 to 4 of wet CS-

[0157] In the production example 1 of the wet state CS, the amount of the neutralizing agent (E...

manufacture example 9

[0167] In Production Example 1 of wet CS, except that 0.18 parts of chlorinated paraffin (Toyoparax 40S) was used as a neutralizing agent, a casting material composition in a wet state was obtained by the same procedure as in Production Example 1 above. (CS9a).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com