Smelting method for directly turning non-quenched and tempered steel

A technology of non-quenched and tempered steel and smelting method, applied in the direction of manufacturing converters, etc., can solve the problems of high scrap rate, difficult to control, difficult to control, etc., achieve high strength and high toughness, ensure service life, and ensure the effect of stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

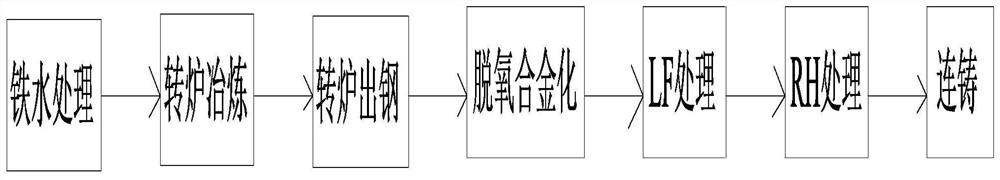

Method used

Image

Examples

Embodiment 1

[0053] The method for smelting high-strength non-quenched and tempered steel provided in this embodiment includes the following steps:

[0054] (1) Pretreatment of molten iron (not necessary), can be adjusted according to the condition of molten iron entering the furnace: reduce the burden of desulfurization in the LF treatment process, and improve the purity of molten steel;

[0055] (2) Converter smelting control: the mass percentage of C at the end point is controlled at 0.184% or the oxygen level of tapping TSO is 300ppm, the tapping temperature is 1630°C, and the oxygen level is strictly controlled to create good conditions for the subsequent process;

[0056] (3), converter tapping control:

[0057] a. Bottom agitation: Turn on the bottom agitation and nitrogen blowing of the converter before the molten steel is tapped to increase the N content in the molten steel, reduce the oxidation of the molten steel and the P content of the molten steel;

[0058] b. Control of sla...

Embodiment 2

[0072] The method for smelting high-strength non-quenched and tempered steel provided in this embodiment includes the following steps:

[0073] (1) Hot metal pretreatment (not necessary), can be adjusted according to the molten iron into the furnace (such as hot metal S ≤ 0.01%, desulfurization is not required): reduce the desulfurization burden in the LF treatment process, and improve the purity of molten steel;

[0074] (2) Converter smelting control: End point control C: 0.254% (tapping TSO: 220ppm), tapping temperature: 1625°C, strictly control the oxygen level, and create good conditions for the subsequent process;

[0075] (3), converter tapping control:

[0076] a. Bottom agitation: Turn on the bottom agitation and nitrogen blowing of the converter before the molten steel is tapped to increase the N content in the molten steel, reduce the oxidation of the molten steel and the P content of the molten steel;

[0077] b. Control of slag removal: slag dumping before the co...

Embodiment 3

[0091] The preparation method of the high-purity wind power fastener provided in this embodiment includes the following steps:

[0092] (1) Hot metal pretreatment (not necessary), can be adjusted according to the molten iron into the furnace (such as hot metal S≤0.01% without desulfurization): reduce the burden of desulfurization in the LF treatment process, and improve the purity of molten steel;

[0093] (2) Converter smelting control: End point control C: 0.292% (or tapping TSO oxygen level 180ppm), tapping temperature 1630°C, strictly control the oxygen level, and create good conditions for the subsequent process;

[0094] (3) Converter tapping control:

[0095] a. Before the molten steel is tapped, turn on the bottom of the converter to stir and blow nitrogen, increase the N content in the molten steel, reduce the oxidation of the molten steel and the P content of the molten steel;

[0096] b. Control of slag removal: slag dumping before the converter is tapped, and a do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com