Production method of large-repose-angle fluxed pellets

A production method and flux-based technology, which are applied in the field of large-angle flux-based pellet production, can solve the problems of easy rolling of pellets and unstable blast furnace airflow, so as to improve the stacking angle of pellets, widen the scope of use, and reduce rolling. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

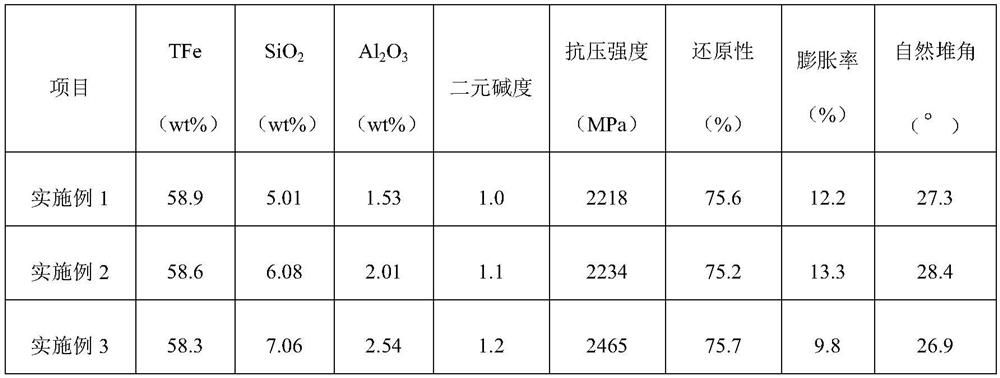

Examples

Embodiment 1

[0027] The specific production process of the large-heap angle flux pellet production method:

[0028] (1) Proportioning according to the following composition requirements: SiO 2 5wt%, Al 2 o 3 1.5wt%, Na 2 O is 0.511wt%, binary alkalinity is controlled at 1.0, and the proportion of red mud is 5wt%, and the composition of red mud used is shown in Table 1. The ratio of high-silicon iron ore powder and quicklime is calculated according to the above requirements.

[0029] Table 1 Red mud composition (wt,%)

[0030] Element Fe 2 o 3

SiO 2

Al 2 o 3

CaO Na 2 o

content 43.12 16.32 20.40 7.98 10.22

[0031] (2) The raw materials are mixed and finely ground, the proportion of mineral powder smaller than 0.074mm is >50%, and the ratio of red mud smaller than 0.074mm is >85%. The two are mixed and then wetted and pelletized.

[0032] (3) Use a sieving machine to sieve out green balls with a particle size range of 6 mm to 10 mm f...

Embodiment 2

[0035] The specific production process of the large-heap angle flux pellet production method:

[0036] (1) Proportioning according to the following composition requirements: SiO 2 6wt%, Al 2 o 3 2wt%, Na 2 O is 0.52wt%, the binary alkalinity is controlled at 1.1, and the proportion of red mud is 4.5wt%. The red mud composition used is shown in Table 2. The ratio of raw materials is calculated according to the above requirements.

[0037] Table 2 red mud composition (wt,%)

[0038] Element Fe 2 o 3

SiO 2

Al 2 o 3

CaO Na 2 o

content 45.21 11.52 14.32 3.96 11.57

[0039] (2) After the raw materials are mixed, they are finely ground, the proportion of mineral powder smaller than 0.074mm is > 60%, and the proportion of red mud smaller than 0.074mm is > 90%. The two are mixed and then wetted and pelletized.

[0040] (3) Use a sieving machine to sieve out green balls with a particle size range of 6mm to 10mm for roasting, and...

Embodiment 3

[0043] The specific production process of the large-heap angle flux pellet production method:

[0044] (1) Proportioning according to the following composition requirements: SiO 2 7wt%, Al 2 o 3 2.5wt%, Na 2 O is 0.501wt%, binary alkalinity is controlled at 1.2, and the proportion of red mud is 4wt%, and the composition of red mud used is shown in Table 3. The proportion of raw materials is calculated according to the above requirements.

[0045] Table 3 red mud composition (wt,%)

[0046] Element Fe 2 o 3

SiO 2

al 2 o 3

CaO Na 2 o

content 44.3 16.26 12.36 4.36 12.53

[0047] (2) The raw materials are mixed and finely ground, the proportion of mineral powder smaller than 0.074mm is >50%, and the proportion of red mud smaller than 0.074mm is >80%. The two are mixed and then wetted and pelletized.

[0048] (3) Use a sieving machine to sieve out green balls with a particle size range of 6mm to 10mm for roasting, and use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com