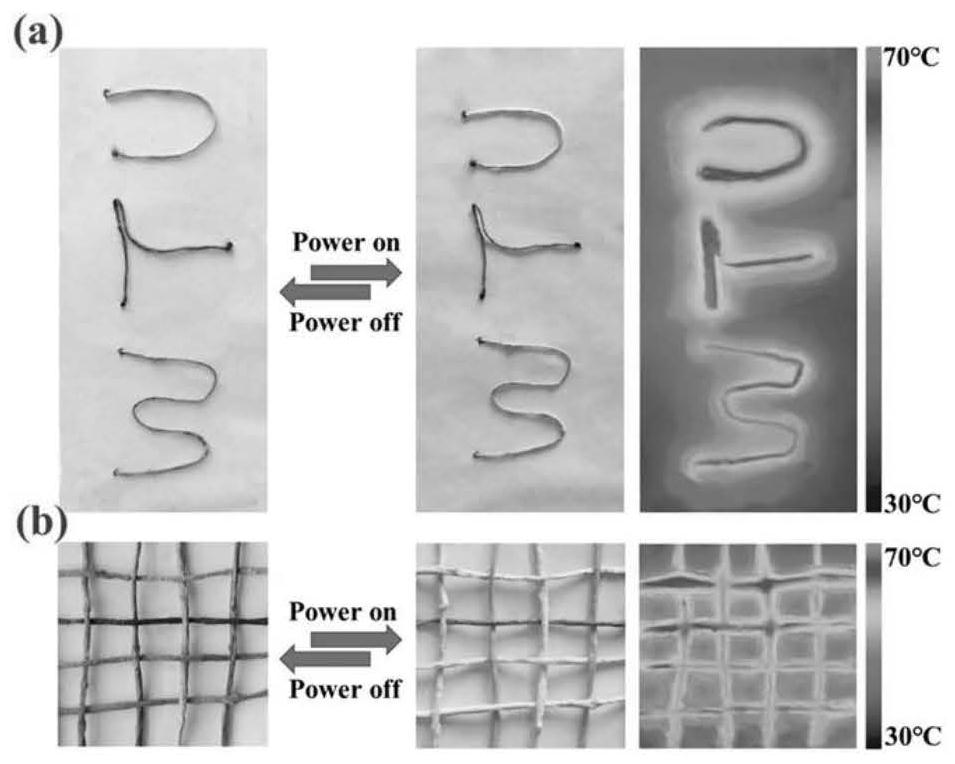

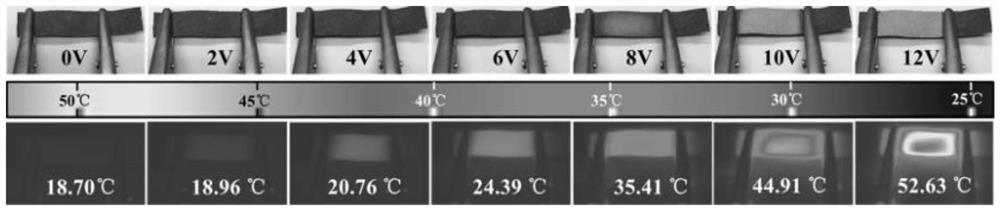

A kind of continuous electrothermochromic fiber based on polyester filament and preparation method thereof

A polyester filament, color-changing technology, used in fiber types, fiber processing, textiles and papermaking, etc., can solve the problems of high cost, difficult mass production, and difficult large-scale continuous production, and achieves short response time, Smooth and uniform surface, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present embodiment provides a preparation method of a continuous electrothermochromic fiber based on polyester filament, including the following steps:

[0046] 1. Preparation of polyester conductive filament by electroless deposition

[0047] 1) Wind the polyester filament on a reel with a diameter of 5cm for 20 minutes, then remove it from the reel. The fiber can maintain a ring shape. Treat the polyester filament with a standard solution of NaOH for 60 minutes to remove grease and impurities on the surface.

[0048] 2) Treat the surface of the polyester filament with a plasma cleaner for 5 minutes to improve its hydrophilic properties; then place it in an ethanol solution with a concentration of 2% (v / v) of vinyltrimethoxysilane (VTMS) for 15 minutes to make it Silane reacts with hydroxyl groups on the fiber surface.

[0049] 3) Using potassium persulfate as an initiator, put the VTMS-modified fibers into an aqueous solution of methacryloyloxyethyltrimethylammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com