Silicon electrolytic bath for preparing high-purity silicon and silicon preparation method

An electrolytic cell and high-purity technology, applied in the field of electrolytic cells, can solve problems such as molten salt atmosphere corrosion and impact on continuous production, and achieve the effects of improving purity, improving automation and mechanization, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited by the examples.

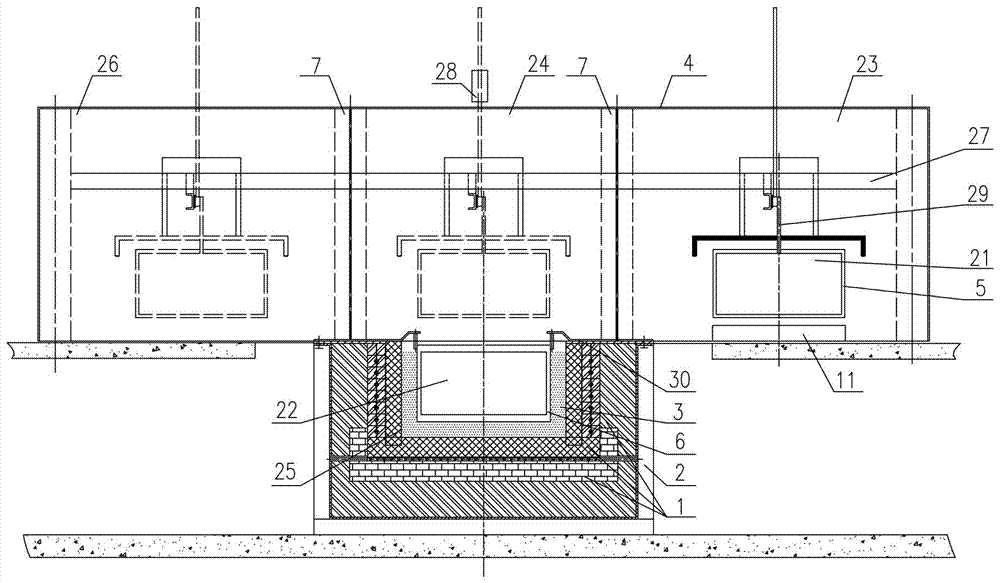

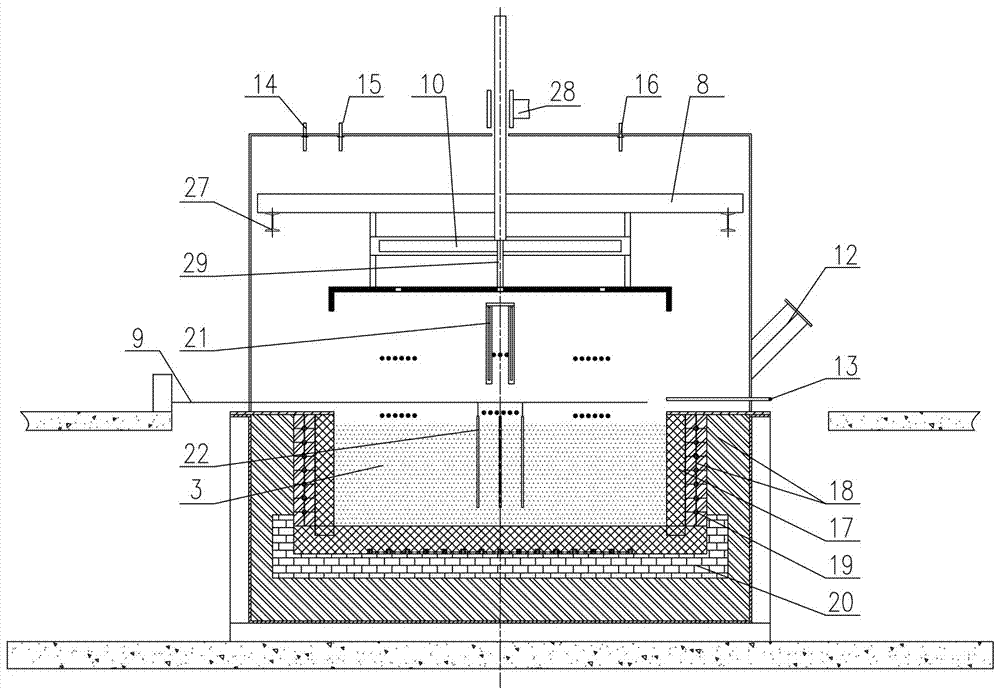

[0024] As shown in the figure, a silicon electrolytic cell for preparing high-purity silicon according to the present invention includes three operating chambers: a cathode preheating chamber 23, an intermediate operating chamber 24, and a crystalline silicon cooling chamber 26 arranged on the same level. Folding doors 7 are arranged between the operating chambers, and an electrolytic reaction chamber 25 communicating with the middle operating chamber 24 is arranged below. A molten electrolyte 3 is provided in the electrolysis reaction chamber 25 , and an anode device 6 is provided in the molten electrolyte 3 . The anode device 6 is used to fix the anode pole piece 22 . The anode pole piece 22 is connected to the positive pole of the DC power supply system through the anode connection 9 . A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com