Preparation method of high-purity calcium levofolinate

A technology for calcium levofolinate and calcium leucovorin is applied in the field of preparation of high-purity calcium levofolinate, and can solve the problems of affecting drug safety, difficult to meet requirements for the purity of calcium levofolinate, unable to meet the standard of chloride ion content, and the like, Achieve the effect of shortening the crystallization time, stabilizing the splitting system, and avoiding chlorine pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Using calcium folinate as raw material, prepare high-purity calcium levofolinate, as follows:

[0070] Suspend 51.1g (0.1 mol) of calcium folinate and 25g of sodium bromide in 400ml of water, heat up to 50°C to dissolve, cool down to 10°C to crystallize for 6 hours, precipitate solids, filter, wash the solids with water, and combine the filtrates.

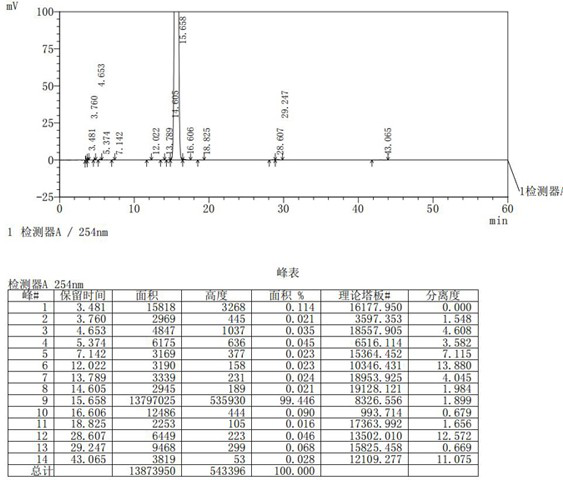

[0071] Add 10g of calcium acetate and 2g of R-(α)-phenylethylamine to the filtrate, cool the solution to 10°C to crystallize for 6 hours, and precipitate a solid, filter, and wash the solid with water to obtain 59g of a single-resolution solid, with a yield of 90%. One-time split heterogeneous map as attached figure 1 , a split impurity map as attached figure 2 .

[0072] Suspend the whole amount of the first split solid in 400ml of water, raise the temperature to 50°C, add acetic acid to dissolve it, add 10g calcium acetate and 2g R-(α)-phenylethylamine to the solution, cool the solution to 10°C to crystallize for 6 hour...

Embodiment 2

[0100] Using calcium folinate as raw material, prepare high-purity calcium levofolinate, as follows:

[0101] Suspend 51.1g (0.1 mol) calcium folinate and 25g sodium bromide in 400ml water, heat up to (40-60)°C to dissolve, cool down to (0-20)°C to crystallize (5-20)h , precipitated solids, filtered, washed the solids, and combined the filtrates.

[0102] Add 8g of calcium formate and 2g of R-(α)-phenylethylamine to the filtrate, cool down the solution to (0-20)°C and crystallize for (5-20) hours, precipitate solids, filter and wash the solids to obtain a resolution Solid 59.5g, yield = 91%.

[0103] Suspend the whole amount of the first split solid in 400ml water, raise the temperature to (40-60)°C, add formic acid to dissolve it, add 8g calcium formate and 2g R-(α)-phenylethylamine to the solution, and cool the solution to ( 0-20) ℃ crystallization (5-20) h, precipitated solid, filtered, washed solid, 50g of secondary resolution solid can be obtained , Yield = 89%.

[01...

Embodiment 3

[0107] Using calcium folinate as raw material, prepare high-purity calcium levofolinate, as follows:

[0108] Suspend 51.1g (0.1 mol) calcium folinate and 25g sodium bromide in 400ml water, heat up to (40-60)°C to dissolve, cool down to (0-20)°C to crystallize (5-20)h , precipitated solids, filtered, washed the solids, and combined the filtrates.

[0109] Add 12g of calcium propionate and 2g of R-(α)-phenylethylamine to the filtrate, cool the solution to (0-20)°C and crystallize for (5-20) hours, precipitate solids, filter, and wash the solids to obtain a one-time solution. Divide solid 60g, yield=90.5%.

[0110] Suspend the whole amount of the first split solid in 400ml water, raise the temperature to (40-60)°C, add propionic acid to dissolve it, add 12g calcium propionate and 2g R-(α)-phenylethylamine to the solution, and cool down the solution Crystallize at (0-20)°C for (5-20) h, precipitate solids, filter, wash the solids with water, and obtain 51.5 g of secondary resol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com