Hardness-controllable low-temperature soluble bridge plug sealing element and preparation method thereof

A seal, low temperature technology, used in sealing/isolation, earthmoving, wellbore/well components, etc., can solve the problem of not being able to effectively adjust the hardness of the seal, and achieve ideal solubility, effective preparation, and surface quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Specifically, the present invention provides a method for preparing a low-temperature soluble bridge plug seal with controllable hardness, comprising the following steps: (1) mixing polyvinyl alcohol resin, plasticizer, acid-binding agent and filler to obtain a raw material mixture ; (2) molding the raw material mixture to obtain a seal body; (3) aging the seal body until the seal body reaches a predetermined hardness to obtain a seal. The present invention uses polyvinyl alcohol resin, plasticizer, acid-binding agent and filler as raw materials, and performs curing treatment on the molded seal body to obtain a seal with flexibly adjustable hardness, so that the seal can reach a suitable hardness and realize Ideal assembly and sealing pressure bearing performance, and the obtained seal has high surface quality and basically no defects. The method can quickly and effectively prepare the sealing member, and has no strict requirements on equipment, operating environment an...

Embodiment 1

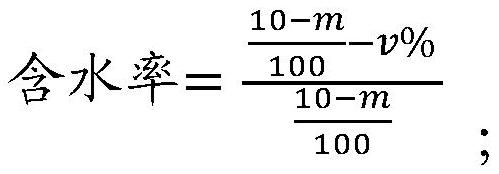

[0072] 100 parts by weight of PVA resin, 62 parts by weight of glycerin, 10 parts by weight of glycerin diacetate, 2 parts by weight of bisphenol A, 2 parts by weight of magnesium hydroxide, and 5 parts by weight of carbon black. After mixing the above raw materials, use molding or extrusion The soluble apron green body A1 is made by injection molding, and the Shore hardness is 94A. The apron body was left open and aged at 28 degrees Celsius and 71% humidity for 24 hours to obtain the apron. The Shore hardness of the apron was 75A and the moisture content was 23.74%. The surface quality of the rubber ring body is good, and the surface quality of the rubber ring is good.

Embodiment 2

[0074] The same as in Example 1, the difference is that the apron body A1 is left open and aged at 23.6 degrees Celsius and 58% humidity for 10 hours to obtain an apron with a Shore hardness of 85A and a moisture content of 5.35%. The surface quality of the apron is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com