Preparation method of efficient anti-sticking kettle coating agent for polyvinyl chloride suspension polymerization

A technology of suspension polymerization and polyvinyl chloride, which is applied in the direction of coating, etc., can solve the problems of increasing the complexity of preparation, and achieve the effects of enhancing storage and use stability, good clarity and transparency, and enhancing anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

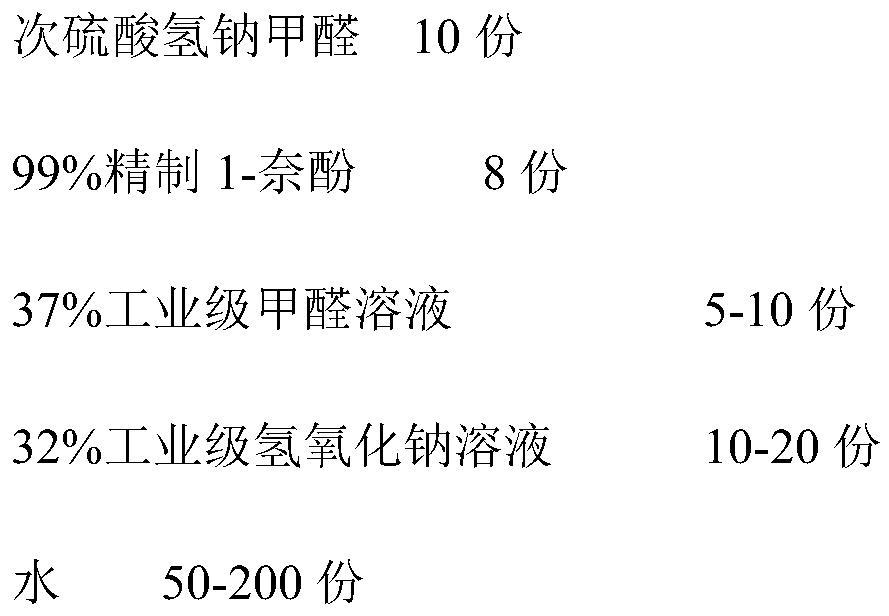

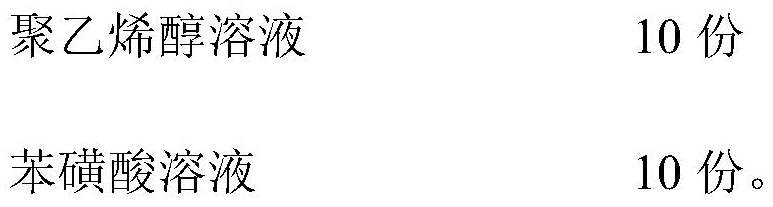

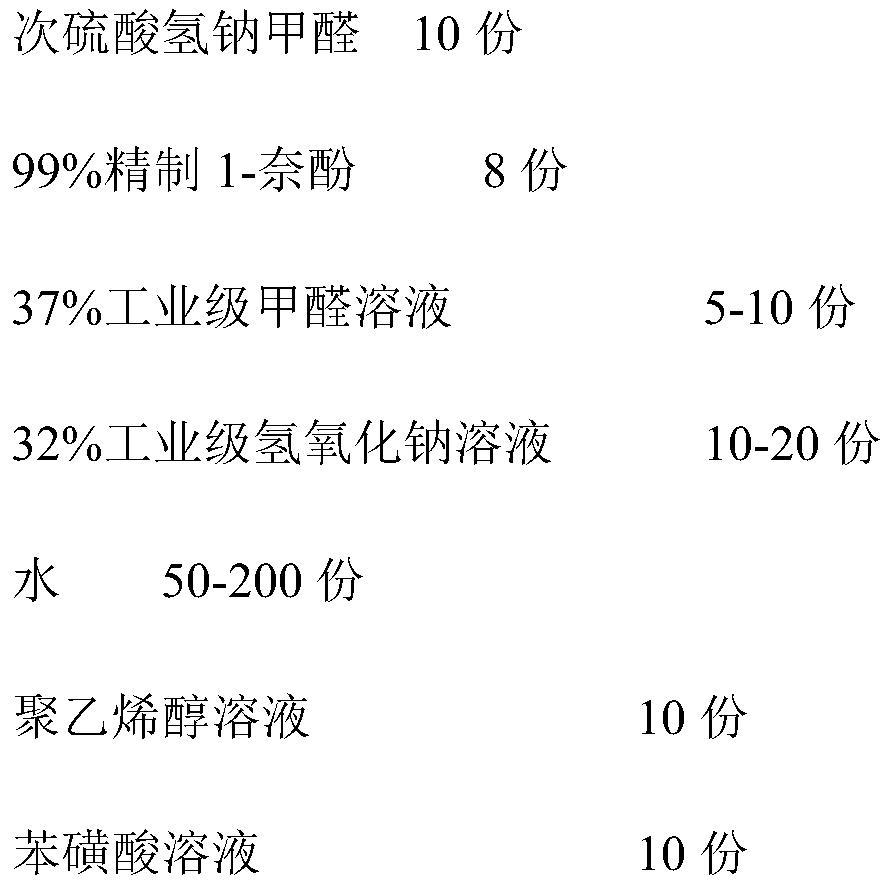

Embodiment 1

[0049] Add 8 parts of 99% refined 1-naphthol, 50 parts of water, and 10 parts of 32% sodium hydroxide solution into the reactor, start stirring, and replace the air in the reactor with nitrogen; heat the reactor until the reaction temperature is stable at 95°C, Slowly add a mixture of 10 parts of sodium sulfoxylate formaldehyde and 10 parts of formaldehyde aqueous solution to the reactor, dropwise for 2 hours, to ensure that the reactor is an alkaline environment, and the pH value is 11-13; After continuing to react for 4 hours, cool to room temperature, add 100 parts of water, 10 parts of benzenesulfonic acid aqueous solution and 10 parts of polyvinyl alcohol aqueous solution, stir for 30 minutes, and let it stand for 10 days to obtain a transparent water-soluble phenolic resin with a specific gravity of 5%-6%. Pale yellow anti-stick kettle coating product.

Embodiment 2

[0051] Add 8 parts of 99% refined 1-naphthol, 50 parts of water, and 15 parts of 32% sodium hydroxide solution into the reactor, start stirring, and replace the air in the reactor with argon; heat the reactor until the reaction temperature is stable at 97°C , slowly drop a mixture of 10 parts of sodium sulfoxylate formaldehyde and 10 parts of formaldehyde aqueous solution into the reactor for 2 hours to ensure that the reactor is an alkaline environment with a pH value of 11-13; After continuing to react for 8 hours, cool to room temperature, add 100 parts of water, 10 parts of benzenesulfonic acid aqueous solution and 10 parts of polyvinyl alcohol aqueous solution, stir for 30 minutes, and let it stand for 12 days to obtain a water-soluble phenolic resin with a specific gravity of 5%-6%. Transparent light yellow anti-stick kettle coating product.

Embodiment 3

[0053]Add 8 parts of 99% refined 1-naphthol, 50 parts of water, and 15 parts of 32% sodium hydroxide solution into the reactor, start stirring, and replace the air in the reactor with nitrogen; heat the reactor until the reaction temperature is stable at 100°C, Slowly add a mixture of 5 parts of sodium bisulfite formaldehyde and 10 parts of formaldehyde aqueous solution to the reactor, dropwise for 1 hour, to ensure that the reactor is an alkaline environment, and the pH value is 11-13; After continuing to react for 8 hours, cool to room temperature, add 100 parts of water, 10 parts of benzenesulfonic acid aqueous solution, 10 parts of polyvinyl alcohol aqueous solution and 5 parts of sodium bisulfite formaldehyde, stir for 20 minutes, and let stand for 13 days to obtain the specific gravity of water-soluble phenolic resin It is a 5%-6% transparent light yellow anti-sticking kettle coating agent product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com