Fuel cell electrode and preparation method and application thereof

A fuel cell electrode and fuel cell technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of non-uniform dispersion of co-catalysts and non-uniform electrode catalysts, so as to optimize the three-phase reaction interface, improve catalytic performance and Output power, improve contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

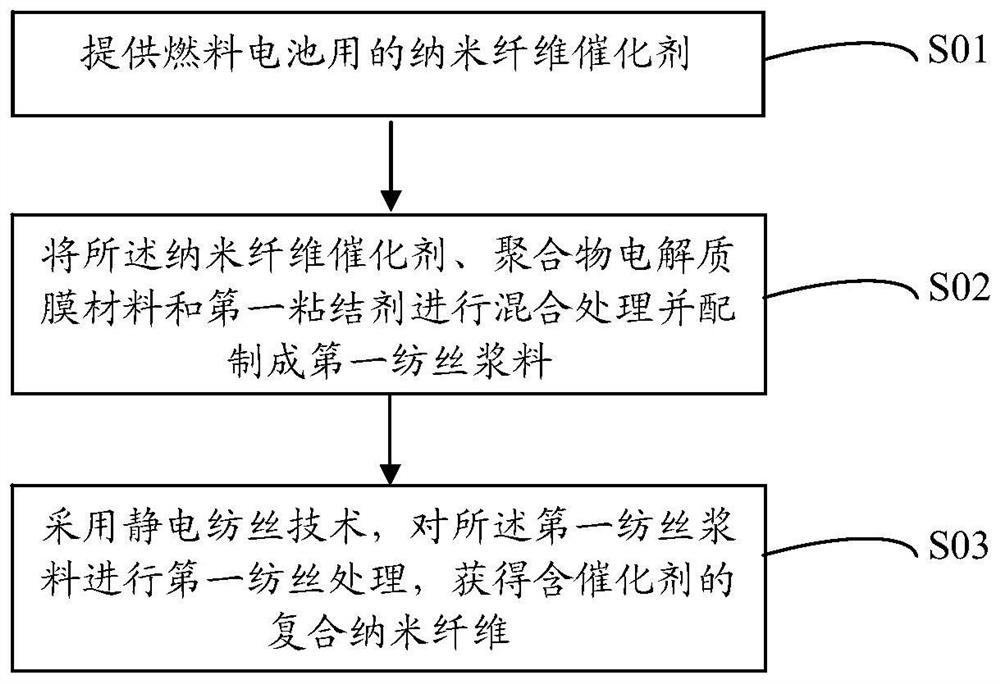

[0029] Based on the fuel cell electrode described above, an embodiment of the present invention also provides a preparation method of the fuel cell electrode. The preparation method technological process of described fuel cell electrode is as follows figure 1 As shown, it includes the following steps:

[0030] Step S01: providing a nanofiber catalyst for fuel cells;

[0031] Step S02: Mixing the nanofiber catalyst, the polymer electrolyte membrane material and the first binder and preparing the first spinning slurry;

[0032] Step S03: Using electrospinning technology, performing a first spinning treatment on the first spinning slurry to obtain catalyst-containing composite nanofibers.

[0033] Wherein, in the step S01, as an example, the method for providing the nanofiber catalyst for a fuel cell includes the following steps:

[0034] Step S011: mixing the soluble platinum source, the soluble tungsten source and the second binder and preparing a second spinning slurry;

...

Embodiment 11

[0048] This embodiment provides a fuel cell electrode and a preparation method thereof. The fuel cell electrode is prepared by a method comprising the following steps:

[0049] S11. Preparation of Pt / WO 3 / C nanofiber catalyst:

[0050] a is mixed with the second spinning size:

[0051] Weigh 1g of chloroplatinic acid, 1g of ammonium tungstate and 2.5g of 8wt.% polyvinylpyrrolidone solution, mix evenly, and after ultrasonication for 4h, stir for 24h to prepare the second spinning slurry;

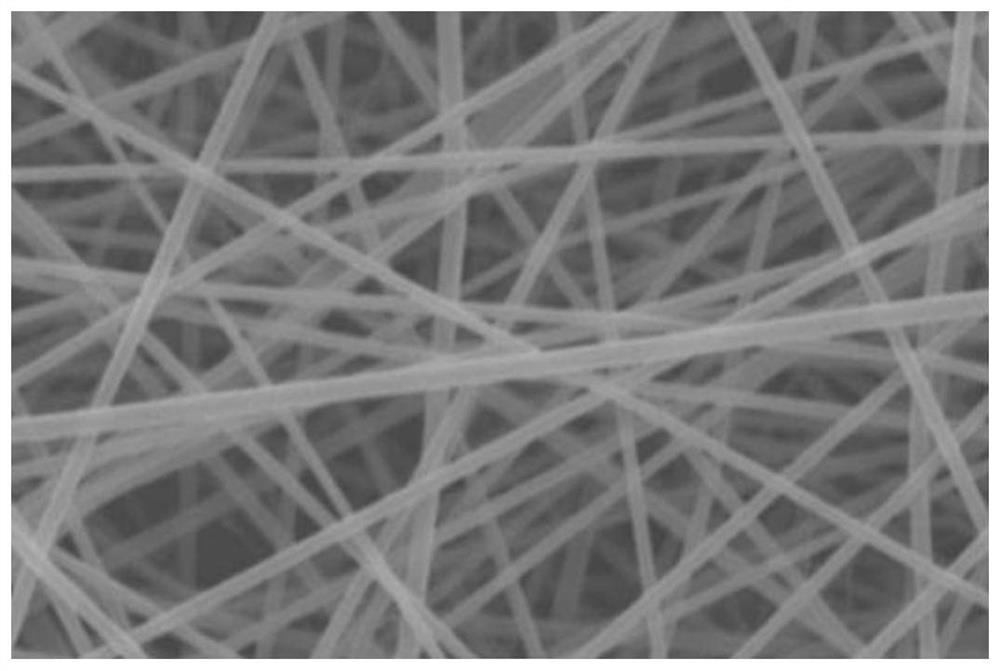

[0052] b Preparation of chloroplatinic acid / ammonium tungstate / polyvinylpyrrolidone nanofibers by electrospinning technology:

[0053] Use the second spinning slurry as raw material, wrap aluminum foil on the surface of the drum receiver, and receive the nanofibers obtained by spinning; the condition parameters are: the liquid flow rate is 0.6mL h -1 , the distance between the needle tip and the drum receiver is 16cm, the voltage is 12kV, and the receiving time is 2.5h to obtain chloropl...

Embodiment 12

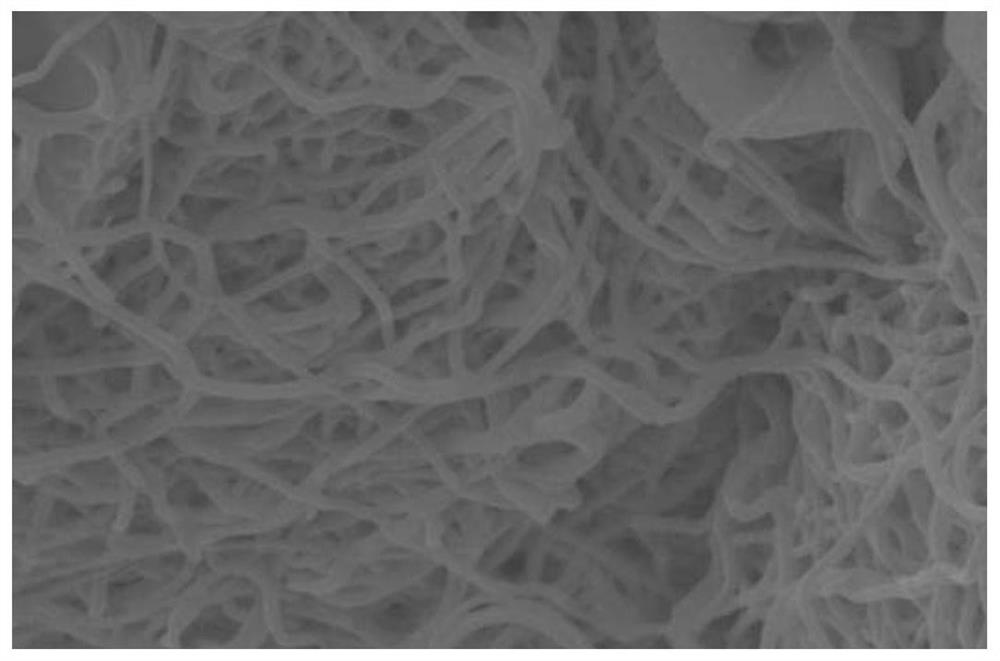

[0067] This embodiment provides a fuel cell electrode and a preparation method thereof. The preparation method of the fuel cell electrode is different from that of Example 11 in that: the prepared Pt loading is 0.05-0.09 mg cm -2 , Pt and WO 3 Catalyst-containing composite nanofibers with a mass ratio of 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com