Preparation method of optical-grade dysprosium oxide magneto-optical transparent ceramic

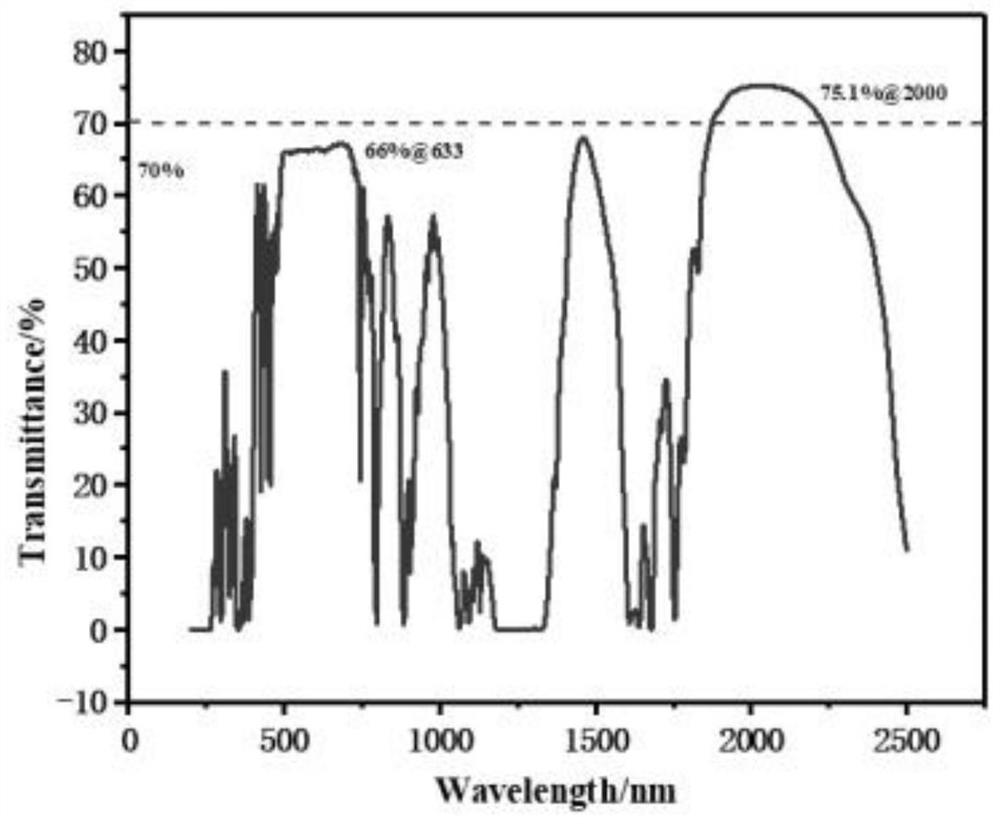

A technology of transparent ceramics and dysprosium oxide, which is applied in the field of preparation of optical-grade dysprosium oxide magneto-optical transparent ceramics, can solve the problems of complex preparation process, long preparation cycle, low transmittance, etc., and achieve simple preparation process, low cost, sintering active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of optical-grade dysprosium oxide magneto-optical transparent ceramics, the specific steps are:

[0024] (1) The synthesis of dysprosium oxide nanocrystalline powder includes: configuring Dy(NO 3 ) 3 Rare earth solution, add 5at.%La(NO 3 ) 3 Mix well; use the positive drop method to drip the precipitant solution (the molar ratio of ammonia water: ammonium bicarbonate is 1:5) into 5at.%La:Dy(NO 3 ) 3 In the mother liquor and continue to stir until the pH value of the precipitation solution reaches a fixed value, stop titration and stirring;

[0025] (2) aging the precipitated solution for 4-12h;

[0026] (3) Washing, drying, and sieving the sample obtained in step (2) in sequence, and calcining in a muffle furnace at 900° C. for 2 h to obtain nanopowder.

[0027] (4) Dry pressing and cold isostatic pressing of the nano-powder in step (3) to obtain a ceramic green body; placing the green body in a high-temperature atmosphere furnace for sinterin...

Embodiment 2

[0031] A preparation method of optical-grade dysprosium oxide magneto-optical transparent ceramics, the specific steps are:

[0032] (1) The synthesis of dysprosium oxide nanocrystalline powder includes: configuring Dy(NO 3 ) 3 Rare earth solution, add 5at.%La(NO 3 ) 3 Mix well; use the positive drop method to drip the precipitant solution (the molar ratio of ammonia water: ammonium bicarbonate is 1:5) into 5at.%La:Dy(NO 3 ) 3 In the mother liquor and continue to stir until the pH value of the precipitation solution reaches a fixed value, stop titration and stirring;

[0033] (2) aging the precipitated solution for 4-12h;

[0034] (3) Washing, drying, and sieving the sample obtained in step (2) in sequence, and calcining in a muffle furnace at 1000° C. for 2 h to obtain nanopowder.

[0035] (4) Dry pressing and cold isostatic pressing of the nano-powder in step (3) to obtain a ceramic green body; placing the green body in a high-temperature atmosphere furnace for sinteri...

Embodiment 3

[0039] A preparation method of optical-grade dysprosium oxide magneto-optical transparent ceramics, the specific steps are:

[0040] (1) The synthesis of dysprosium oxide nanocrystalline powder includes: configuring Dy(NO 3 ) 3 Rare earth solution, add 5at.%La(NO 3 ) 3 Mix well; use the positive drop method to drip the precipitant solution (the molar ratio of ammonia water: ammonium bicarbonate is 1:5) into 5at.%La:Dy(NO 3 ) 3 In the mother liquor and continue to stir until the pH value of the precipitation solution reaches a fixed value, stop titration and stirring;

[0041] (2) aging the precipitated solution for 4-12h;

[0042] (3) After washing, drying and sieving the samples obtained in step (2), they were calcined in a muffle furnace at 1100° C. for 2 hours to obtain nanopowders.

[0043] (4) Dry pressing and cold isostatic pressing of the nano-powder in step (3) to obtain a ceramic green body; placing the green body in a high-temperature atmosphere furnace for sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com