Bi-crosslinked chitosan poly(ester-urethane) modified oxidized starch and preparation method thereof

A technology for oxidizing starch and chitosan, applied in the field of natural polymer materials, can solve the problems of poor biodegradation and absorption performance, cannot be used in the medical field, and difficult to adjust performance, and achieves enhanced water resistance, easy-to-operate components, and good biological properties. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 10g-NCO-terminated poly(ε-caprolactone) (number average molecular weight is 2000g / mol) and 7.04g chitosan (molecular weight is 2000g / mol, degree of deacetylation 92%) (-NCO and -NH 2 The molar ratio is 1:4) was dissolved in 25mL of N,N-dimethylformamide (DMF) at 5°C, heated to 20°C, and reacted under stirring until the infrared detection-NCO characteristic absorption peak disappeared (about 1.6h), Add the DMF dispersion (12.5g dispersed in 60mL DMF) of oxidized starch (aldehyde group content 1.2mmol / g), react under stirring until the solution becomes viscous (about 15min), stop stirring, and remove the dissolved gas under reduced pressure, Slowly pour it into the mold, let it stand at 40°C to evaporate the solvent to form a film (about 60h), and finally dry the film material under reduced pressure to constant weight to obtain chitosan poly(ester-urethane) modified oxidized starch film M1 .

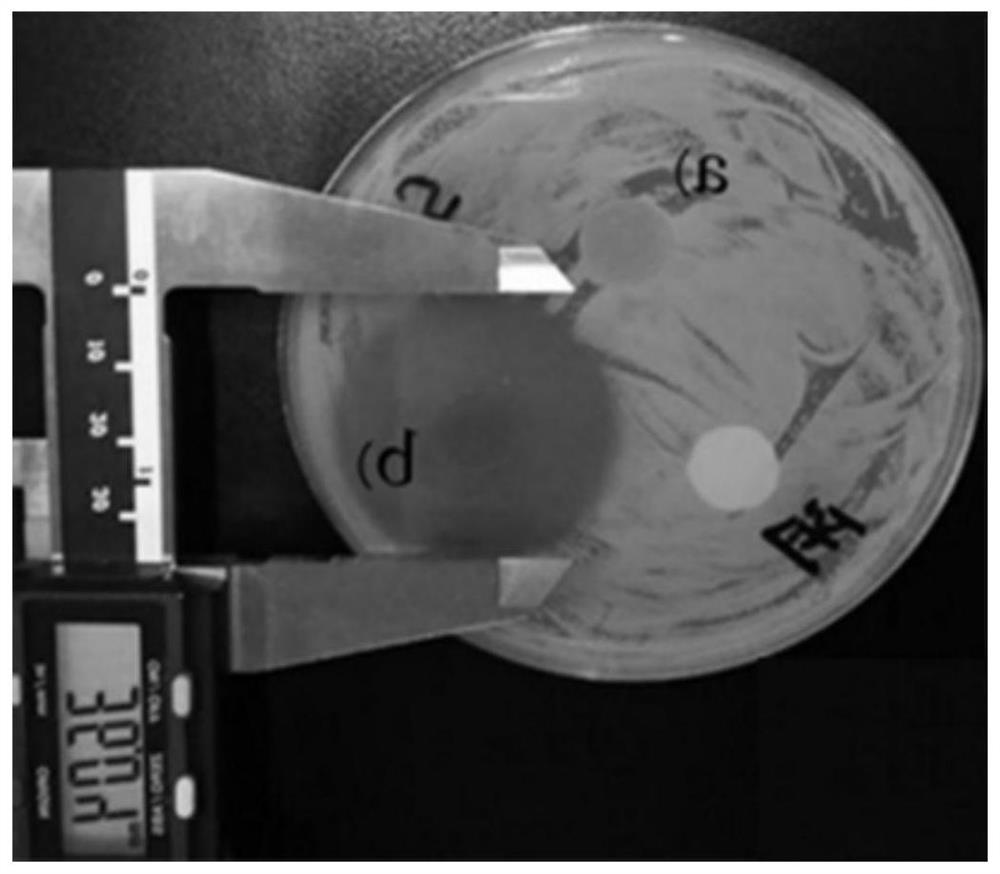

[0046] The picture of the M1 sample prepared in Example 1 is as figure 1 As s...

Embodiment 2

[0048] 10g-NCO-terminated poly(L-lactide) (number average molecular weight is 2000g / mol) and 7.04g chitosan (molecular weight is 2800g / mol, degree of deacetylation 92%) (-NCO and -NH 2 molar ratio of 1:4) was dissolved in 25mL of N,N-dimethylformamide (DMF) at 5°C, heated to 20°C, and reacted under stirring until the infrared detection-NCO characteristic absorption peak disappeared, and oxidized starch (aldehyde DMF dispersion (12.5g dispersed in 60mL DMF) with a base content of 1.2mmol / g), react under stirring until the solution becomes viscous (about 15min), stop stirring, remove the dissolved gas under reduced pressure, and slowly pour it into the mold in 40° C. to allow the solvent to volatilize to form a film (about 60 h), and finally dry the film material under reduced pressure to constant weight to obtain chitosan poly(ester-urethane) modified oxidized starch film M2.

Embodiment 3

[0050] 7.5g-NCO-terminated poly(ε-caprolactone) (number-average molecular weight is 1500g / mol) and 7.04g chitosan (molecular weight is 2800g / mol, degree of deacetylation 92%) (-NCO and -NH 2 The molar ratio is 1:4) was dissolved in 20mL of N,N-dimethylformamide (DMF) at 5°C, heated to 20°C, and reacted under stirring until the infrared detection-NCO characteristic absorption peak disappeared (about 1.5h), Add the DMF dispersion (13.6g dispersed in 65mL DMF) of oxidized starch (aldehyde group content 1.1mmol / g), react under stirring until the solution becomes viscous (about 18min), stop stirring, and remove the dissolved gas under reduced pressure, Slowly pour it into the mold, let it stand at 40°C to evaporate the solvent to form a film (about 60h), and finally dry the film material under reduced pressure to constant weight to obtain chitosan poly(ester-urethane) modified oxidized starch film M3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com