Polyimide waterborne epoxy coating and preparation method thereof

A polyimide water-based and epoxy coating technology, used in the coating field, can solve the problems of limited types of water-based epoxy resin coating resins and poor performance, and achieve improved anti-floating and blooming properties, strong water resistance, and improved performance. The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

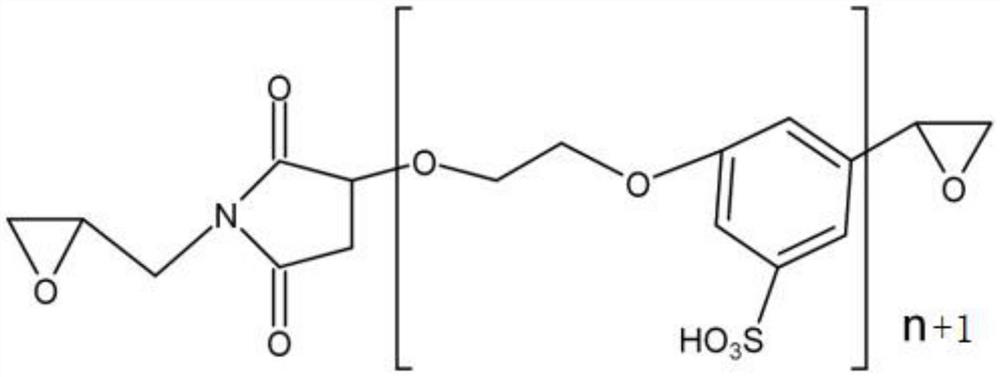

[0039] Prepare polyimide aqueous epoxy resin, the method is as follows:

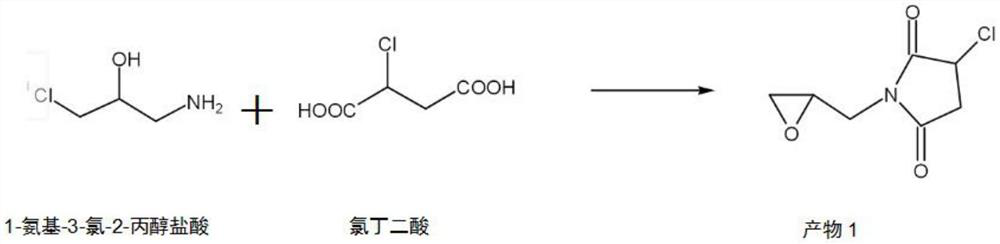

[0040] (1) Add 1 mol of 1-amino-3-chloro-2-propanol hydrochloric acid and 1 mol of chlorosuccinic acid into NaOH aqueous solution (sodium hydroxide concentration 0.5 mol / L, dosage 1 L), stir and react at room temperature for 1 h, Solution I was prepared.

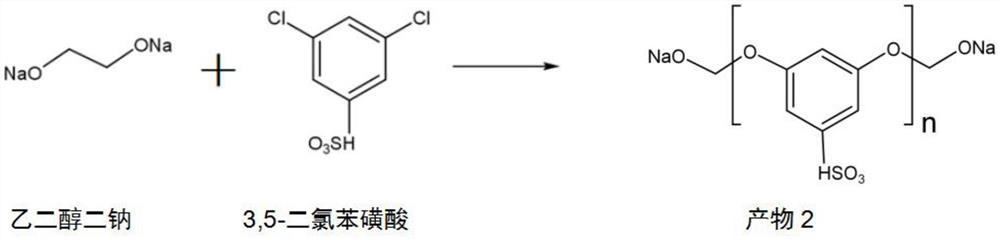

[0041] (2) Add 1 mol of disodium ethylene glycol and 1 mol of 3,5-dichlorobenzenesulfonic acid into NaOH aqueous solution (sodium hydroxide concentration 0.5 mol / L, dosage 1 L), stir and react at room temperature for 0.5 h to obtain Solution II.

[0042] (3) The solution I, the solution II and 1 mol of 3-chloro-5-epoxymethylbenzenesulfonic acid were mixed and stirred for 3 hours to prepare a polyimide water-based epoxy resin.

Embodiment 2

[0044] Prepare polyimide aqueous epoxy resin, the method is as follows:

[0045] (1) Add 1 mol of 1-amino-3-chloro-2-propanol hydrochloric acid and 1 mol of chlorosuccinic acid into NaOH aqueous solution (sodium hydroxide concentration 0.5 mol / L, dosage 1 L), stir and react at 40°C for 1 h , to prepare solution I.

[0046] (2) Add 20 mol of disodium ethylene glycol and 20 mol of 3,5-dichlorobenzenesulfonic acid into NaOH aqueous solution (sodium hydroxide concentration 0.5 mol / L, dosage 20 L), stir and react at 40°C for 0.5 h to prepare Solution II was obtained.

[0047] (3) Mix solution I, solution II with 1 mol of 3-chloro-5-epoxymethylbenzenesulfonic acid, stir and react at 40° C. for 3 hours to prepare a polyimide water-based epoxy resin.

Embodiment 3

[0049] A kind of polyimide water-based epoxy coating, comprises the component of following mass percentage: 50 parts of polyimide water-based epoxy resins of bisphenol A type epoxy resin, embodiment 1 preparation, 0.5 part of ethylenediamines , 1 part of Lewis acid, 1 part of BYK-3101, 0.1 part of sodium oleate, 1 part of GPE type defoamer, 5 parts of titanium dioxide, 8 parts of molybdenum chrome orange, 20 parts of calcium carbonate, 30 parts of mica powder, and 50 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com