Graphene copper-based composite material and preparation method and application thereof

A copper-based composite material, graphene technology, applied in metal rolling and other directions, can solve the problem of inability to effectively meet the power transmission performance and strength requirements of cables, and achieve the advantages of convenient use, good mechanical properties, good electrical conductivity and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

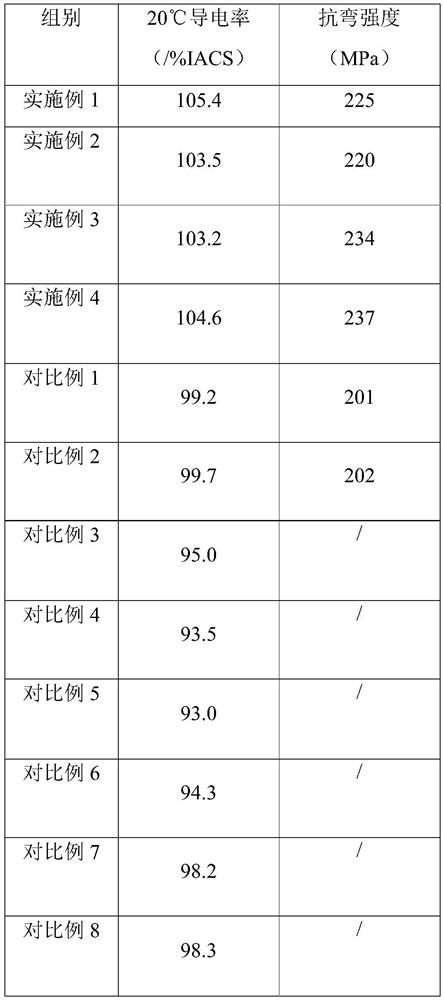

Examples

Embodiment 1

[0025] The present embodiment provides a kind of preparation method of graphene copper-based composite material, comprises the steps:

[0026] 1) The first copper plate and the second copper plate are ultrasonically cleaned with acetone, and then a graphene layer is laid on the first copper plate. The graphene layer is formed by 5-10 layers of monoatomic layer graphene. The thickness of ene is 1nm, and then the second copper plate is laid on the graphene layer, so that the graphene layer is sandwiched between the first copper plate and the second copper plate to form a sandwich structure of "copper-graphene-copper", and graphite An alkene interlayer blank sample; the copper content of the first copper plate and the second copper plate is 99.9%, the thickness of the first copper plate and the second copper plate is 3mm, the length is 60mm, and the width is 20mm;

[0027] 2) Roll the interlayer blank along the z-axis direction, the rolling temperature is 25°C, the rolling speed ...

Embodiment 2

[0031] The present embodiment provides a kind of preparation method of graphene copper-based composite material, comprises the steps:

[0032] 1) The first copper plate and the second copper plate are ultrasonically cleaned with acetone, and then a graphene layer is laid on the first copper plate. The graphene layer is formed by 5-10 layers of monoatomic layer graphene. The thickness of alkene is 1.5nm, then the second copper plate is laid on the graphene layer, so that the graphene layer is sandwiched between the first copper plate and the second copper plate to form a sandwich structure of "copper-graphene-copper", obtaining Graphene interlayer blank sample; the copper content of the first copper plate and the second copper plate is 99.9%, the thickness of the first copper plate and the second copper plate is 3mm, the length is 60mm, and the width is 20mm ;

[0033] 2) Roll the interlayer blank sample downward along the z-axis direction at a rolling temperature of 25°C. Aft...

Embodiment 3

[0037] The present embodiment provides a kind of preparation method of graphene copper-based composite material, comprises the steps:

[0038] 1) The first copper plate and the second copper plate are ultrasonically cleaned with acetone, and then a graphene layer is laid on the first copper plate. The graphene layer is formed by 10-20 layers of monoatomic layer graphene. The thickness of alkene is 2nm, and then the second copper plate is laid on the graphene layer, so that the graphene layer is sandwiched between the first copper plate and the second copper plate to form a sandwich structure of "copper-graphene-copper", and graphite is obtained. An alkene interlayer blank sample; the copper content of the first copper plate and the second copper plate is 99.9%, the thickness of the first copper plate and the second copper plate is 3mm, the length is 60mm, and the width is 20mm;

[0039] 2) Roll the interlayer blank sample downward along the z-axis direction at a rolling temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com