Conductive composite fluoroether rubber and preparation method thereof

A technology of fluoroether rubber and compound fluorine, which is applied in the field of conductive compound fluoroether rubber and its preparation, can solve the problems of less research on fluoroether rubber, and achieves good market prospects, good electrical conductivity and mechanical properties, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

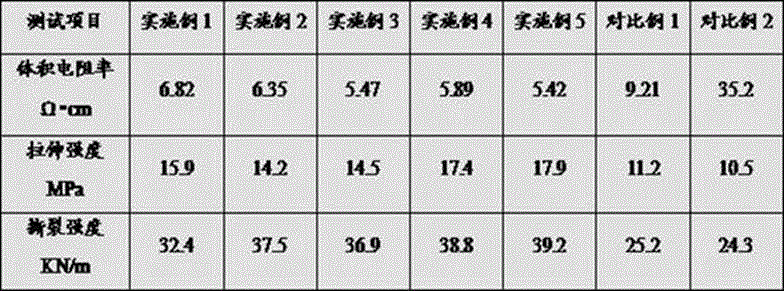

Examples

Embodiment 1

[0024] A conductive composite fluoroether rubber, prepared from the following components in parts by weight: 52 parts of fluoroether rubber, 34 parts of nitrile rubber, 6 parts of adamantine, 4 parts of tantalum powder, 3 parts of nickel sulfate, nano-chloride 4 parts of zinc chloride, 2 parts of calcium stearate, 5 parts of conductive filler, 2 parts of titanium chloride, 1 part of methyltriacetone oximinosilane, 7 parts of 2-mercaptobenzothiazole, 0.5 parts of antioxidant MB, compound Accelerator 1 part;

[0025] The conductive filler is a mixture of aluminum-doped zinc oxide, graphene powder, and carbon nanotube powder, and the weight ratio of the three is 1:1:1;

[0026] The composite accelerator includes a compound of accelerator TMTD, accelerator DM and accelerator TT in a weight ratio of 0.3:1:0.5.

[0027] The preparation method of the above-mentioned conductive composite fluoroether rubber, the preparation method comprises the following steps:

[0028] (1) Weigh acc...

Embodiment 2

[0032] A conductive composite fluoroether rubber, prepared from the following components in parts by weight: 68 parts of fluoroether rubber, 50 parts of nitrile rubber, 15 parts of adamantine, 11 parts of tantalum powder, 14 parts of nickel sulfate, nano chloride 12 parts of zinc chloride, 11 parts of calcium stearate, 16 parts of conductive filler, 10 parts of titanium chloride, 6 parts of methyltriacetone oximinosilane, 24 parts of 2-mercaptobenzothiazole, 4 parts of antioxidant MB, composite accelerator 6 copies;

[0033] Described conductive filler is the mixture of graphene powder, carbon nanotube powder, conductive carbon black and the weight ratio of the three is 1:2:1;

[0034] The composite accelerator includes a compound of accelerator TMTD, accelerator DM and accelerator TT in a weight ratio of 0.3:1:0.5.

[0035] The preparation method of the above-mentioned conductive composite fluoroether rubber, the preparation method comprises the following steps:

[0036] (1...

Embodiment 3

[0040] A conductive composite fluoroether rubber, prepared from the following components in parts by weight: 60 parts of fluoroether rubber, 42 parts of nitrile rubber, 10 parts of adamantine, 7 parts of tantalum powder, 8 parts of nickel sulfate, nano chloride 8 parts of zinc chloride, 6 parts of calcium stearate, 10 parts of conductive filler, 6 parts of titanium chloride, 3.5 parts of methyltriacetone oximinosilane, 11 parts of 2-mercaptobenzothiazole, 2.2 parts of antioxidant MB, compound Accelerator 3.5 parts;

[0041] The conductive filler is a mixture of carbon nanotube powder, conductive carbon black and nano silver powder, and the weight ratio of the three is 3:2:0.4;

[0042] The composite accelerator includes a compound of accelerator TMTD, accelerator DM and accelerator TT in a weight ratio of 0.3:1:0.5.

[0043] The preparation method of the above-mentioned conductive composite fluoroether rubber, the preparation method comprises the following steps:

[0044] (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com