Preparation method of flexible electrode of ternary structure

A technology of flexible electrodes and carbon cloth, which is applied in the field of preparation of ternary structure flexible electrodes, can solve problems such as cumbersome and time-consuming processes, increase process difficulty, affect performance, etc., and achieve the effect of easy preparation method, low price and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) 0.616g ammonium fluoride was dissolved in 40mL 2mmol L -1 Stir in nickel nitrate solution for 30min to obtain solution A;

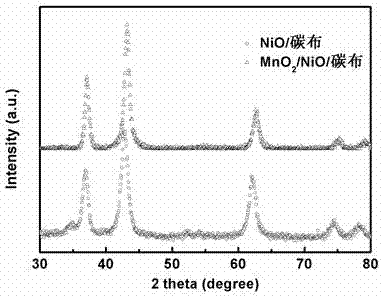

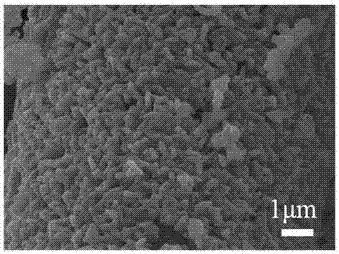

[0040] (2) Transfer solution A into a reaction kettle with a piece of carbon cloth (2cm×3cm), and react at 150°C for 6h. After the reaction, take out the carbon cloth, wash it with a large amount of deionized water, and dry it in an oven at 50°C for 8h. Heat treatment in nitrogen at 450°C for 2 hours to obtain NiO nanosheet / carbon cloth composite material;

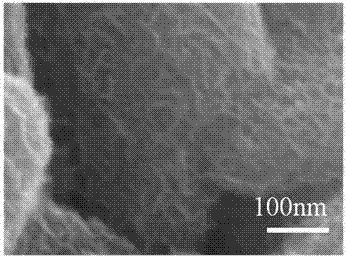

[0041] (3) the obtained in step (2) in 0.05mol L -1 Immerse in potassium permanganate solution at 16°C for 24h, take it out and wash it with deionized water, and then heat-treat at 400°C for 1h to obtain MnO 2 Nanowire / NiO nanosheet / carbon cloth ternary structure electrode material.

[0042] (4) In the three-electrode system, directly use the obtained ternary structure electrode material as the working electrode, use the platinum electrode as the counter electrode, and use the saturated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com