Preparing method of expanded graphite composite wrapped by crosslinking carbon fibers

A technology of expanded graphite and composite materials, applied in carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of low specific surface area of expanded graphite, and achieve the effect of improving overall performance, good electrical conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

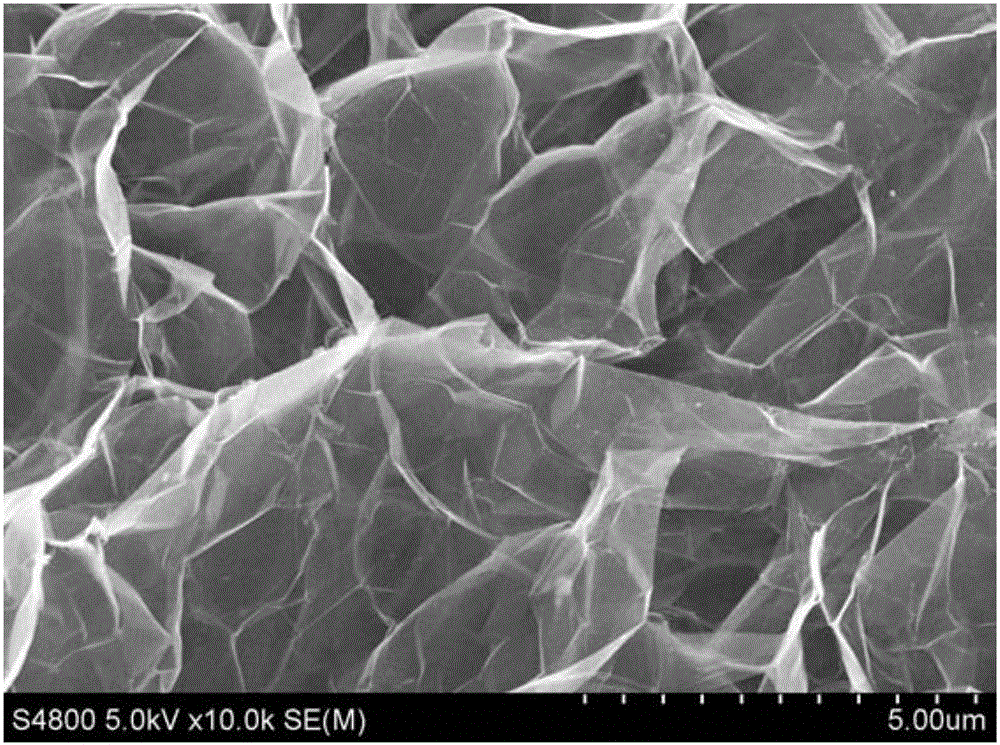

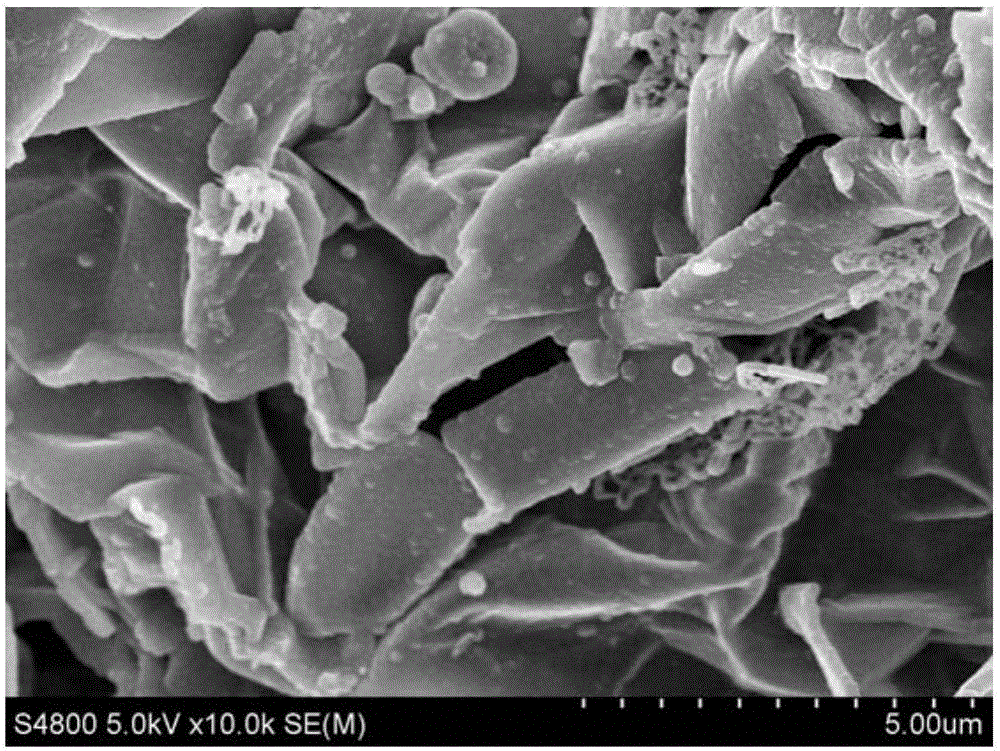

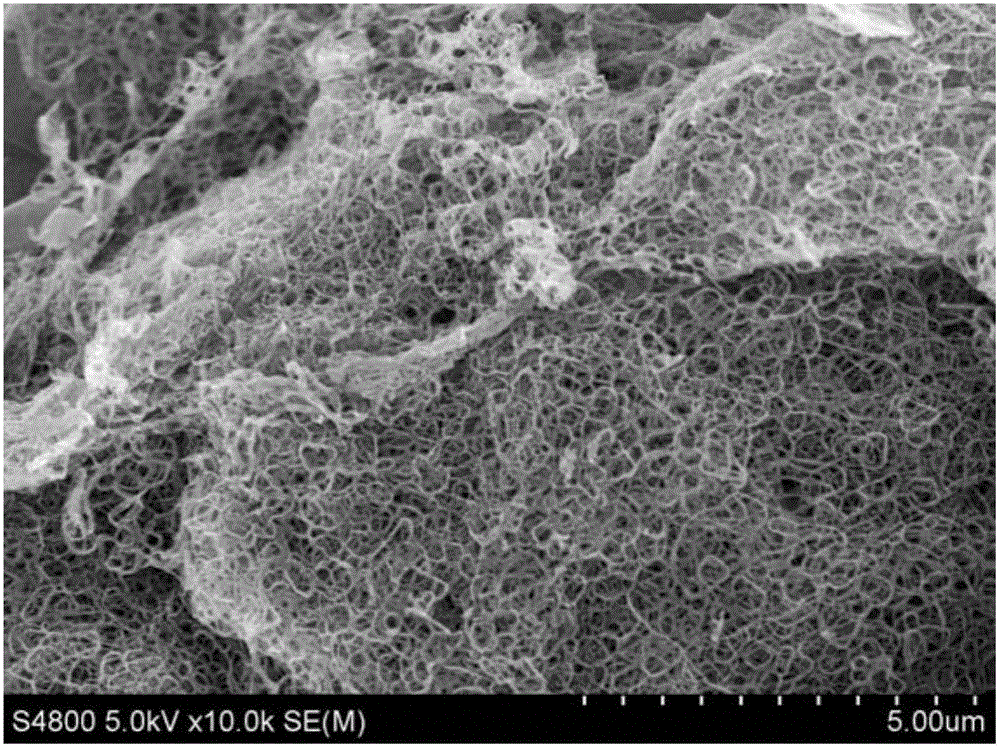

[0017] Embodiment one: the preparation method of the crosslinked carbon fiber coated expanded graphite composite material of the present invention is carried out according to the following steps:

[0018] 1. Mix flake graphite, oxidant and intercalation agent evenly, and stir the reaction for 40-90 minutes at a temperature of 20-60°C to complete the oxidation intercalation reaction, and then add an appropriate amount of H 2 o 2 Reducing the excess oxidant, then filtering out the solid phase, washing with water until neutral, drying to obtain expandable graphite; subjecting the expandable graphite to microwave expansion treatment to obtain expanded graphite (EG);

[0019] Two, cetyltrimethylammonium bromide (CTAB) is dissolved in hydrochloric acid aqueous solution, then add the expanded graphite that step 1 makes, stir, obtain mixed solution A; Under magnetic stirring condition, ammonium persulfate ( APS) was added to the mixed solution A, and continued to stir until uniform t...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the particle size range of the flake graphite in step 1 is 45-75 μm. Others are the same as in the first embodiment.

[0022] Specific embodiment two: this embodiment is different from specific embodiment one or two: the oxidizing agent described in step one is potassium permanganate (KMnO 4 ), potassium dichromate (K 2 Cr 2 o 7 ) or potassium perchlorate (KClO 4 ). Others are the same as in the first or second embodiment.

specific Embodiment approach 4

[0023] Specific embodiment four: this embodiment is different from one of specific embodiments one to three: the intercalation agent described in step one is concentrated sulfuric acid (H 2 SO 4 ), perchloric acid (HClO 4 ), phosphoric acid (H 3 PO 4 ), glacial acetic acid (C 2 h 4 o 2 ) or acetic anhydride (C 4 h 6 o 3 ). Others are the same as those in the first to third specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com