Preparation method of nuclear-grade boron carbide pellet

A boron carbide and pellet technology, which is used in manufacturing tools, ceramic molding machines, etc., can solve problems such as difficulty in control, grain growth, loss of sintering molds, etc., and achieve a complete structure, stable performance, and good physical and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

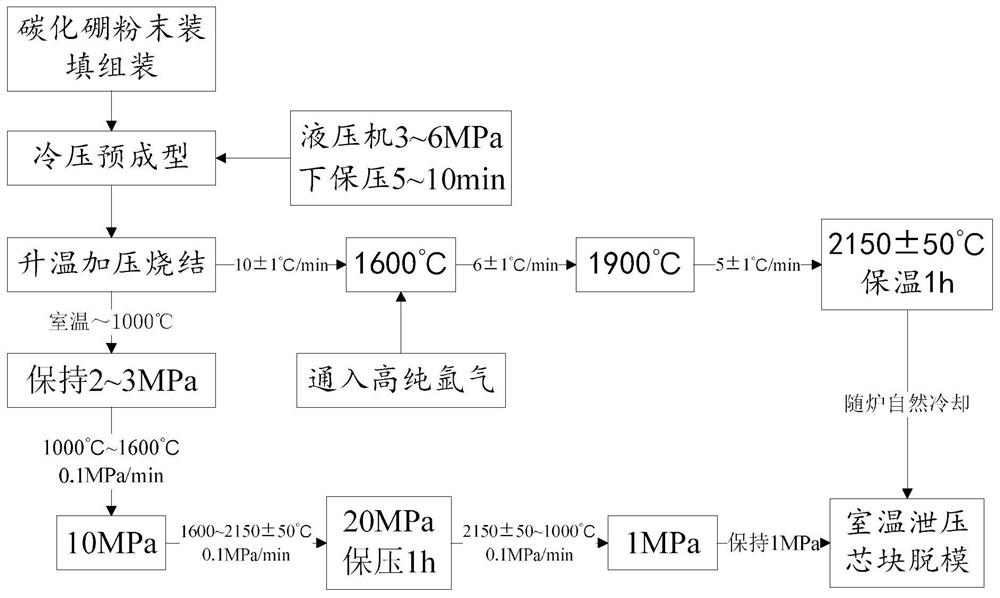

[0024] Such as figure 1 Shown, a kind of preparation method of nuclear grade boron carbide pellet, comprises the steps:

[0025] (1) Loading and assembly: put 10 Boron carbide raw material powder with B enrichment degree ≥ 85% is filled in a mold that conforms to the shape and structure of the desired boron carbide pellet product, wherein the sum of the mass fractions of boron carbide and free boron in the boron carbide raw material powder is ≥ 98.5% , the median particle size D of boron carbide raw material powder 50 is 0.712 μm.

[0026] (2) Cold press preforming: use a hydraulic press to cold press the mold filled with boron carbide raw material powder, and hold the pressure at a forming pressure of 4.5 MPa for 8 minutes to make a preformed boron carbide pellet.

[0027] (3) Heating and pressure sintering: 1) Place the preformed boron carbide core block in a sintering mold made of graphite, put it into a vacuum furnace, evacuate the vacuum furnace to below 10Pa, and rais...

Embodiment 2

[0029] Such as figure 1 Shown, a kind of preparation method of nuclear grade boron carbide pellet, comprises the steps:

[0030] (1) Loading and assembly: put 10 Boron carbide raw material powder with B enrichment degree ≥ 85% is filled in a mold that conforms to the shape and structure of the desired boron carbide pellet product, wherein the sum of the mass fractions of boron carbide and free boron in the boron carbide raw material powder is ≥ 98.5% , the median particle size D of boron carbide raw material powder 50 is 0.865 μm.

[0031] (2) Cold press preforming: use a hydraulic press to cold press the mold filled with boron carbide raw material powder, and hold the pressure for 10 minutes at a forming pressure of 3 MPa to make a preformed boron carbide pellet.

[0032](3) Heating and pressure sintering: 1) Place the preformed boron carbide core block in a sintering mold made of graphite, put it into a vacuum furnace, evacuate the vacuum furnace to below 10Pa, and raise ...

Embodiment 3

[0034] Such as figure 1 Shown, a kind of preparation method of nuclear grade boron carbide pellet, comprises the steps:

[0035] (1) Loading and assembly: put 10 Boron carbide raw material powder with B enrichment degree ≥ 85% is filled in a mold that conforms to the shape and structure of the desired boron carbide pellet product, wherein the sum of the mass fractions of boron carbide and free boron in the boron carbide raw material powder is ≥ 98.5% , the median particle size D of boron carbide raw material powder 50 is 0.632 μm.

[0036] (2) Cold press preforming: use a hydraulic press to cold press the mold filled with boron carbide raw material powder, and hold the pressure for 5 minutes at a forming pressure of 6 MPa to make a preformed boron carbide pellet.

[0037] (3) Heating and pressure sintering: 1) Place the preformed boron carbide core block in a sintering mold made of graphite, put it into a vacuum furnace, evacuate the vacuum furnace to below 10Pa, and raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com