Manufacturing method of silicon carbide micro-reaction assembly and silicon carbide micro-reaction assembly

A manufacturing method, a technology of silicon carbide, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical fixed reactors, etc., can solve the problem of difficult control of micro-flow and silicon carbide micro-reactions It is difficult for components to precisely control the width and depth of microchannels, etc., to achieve precise control, good corrosion resistance, and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

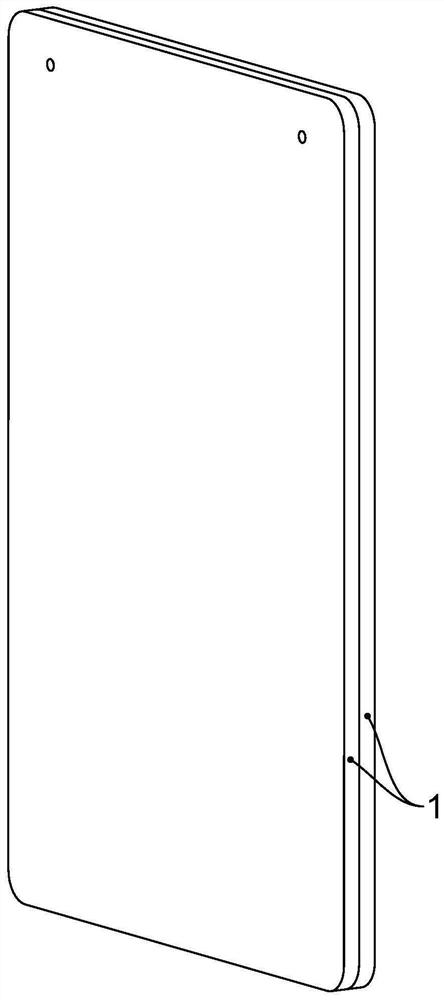

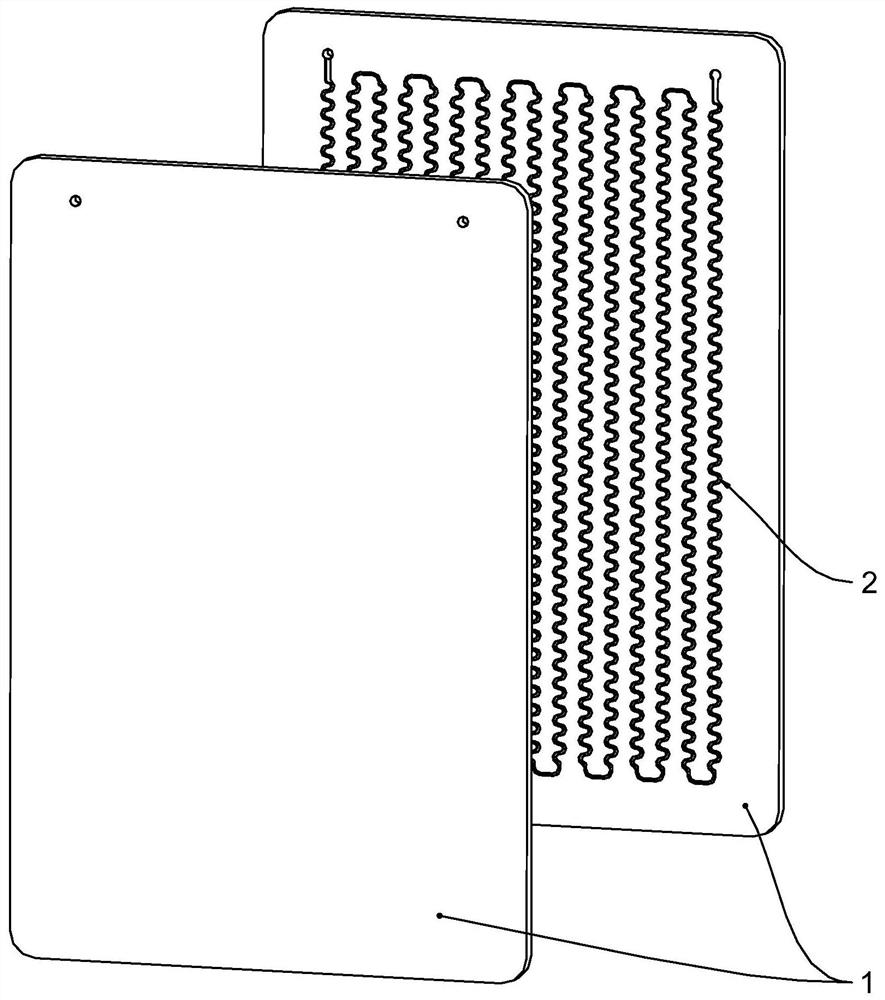

[0042] The silicon carbide micro-reaction assembly includes two reaction plates 1 (such as Figure 1-2 shown), wherein the thickness of the reaction plate 1 is 5 mm, the width of the microchannel 2 is 0.1 mm, and the depth is 0.2 mm.

[0043] The specific manufacturing steps are:

[0044] (A) Plain embryo forming: use silicon carbide to spray granulate powder, and directly isostatic pressing to obtain a green embryo;

[0045] (B) Elemental embryo processing: according to the design size, the reaction plate element embryos are processed in a plane, and the microchannels are not processed;

[0046] (C) High-temperature sintering: the plate obtained in step (B) is sintered under vacuum micro-negative pressure, and the sintering conditions are: 2100°C-2150°C, 0.5 h;

[0047] (D) Reaction plate processing: laser processing technology is used to process microchannels on the required reaction plates, the width of the microchannel is 0.1mm, the depth is 0.2mm, and the inlet and outl...

Embodiment 2

[0050] The silicon carbide micro-reaction assembly includes three reaction plates 1 and two heat exchange plates 3 (such as Figure 3-4 The thickness of the reaction plate 1 in the middle is 8 mm, the thickness of the two reaction plates 1 on both sides is 10 mm, the width of the microchannel 2 is 0.6 mm, the depth is 0.8 mm, and the thickness of the heat exchange plate 3 The width of the heat exchange medium channel 4 is 9 mm and the depth is 3 mm. It is used between the reaction plate 1 and between the reaction plate 1 and the heat exchange plate 3. The welding temperature is 1400 ℃, and the welding pressure is 10 bar.

[0051] The specific manufacturing steps are:

[0052] (A) Plain embryo forming: use silicon carbide to spray granulate powder, and directly isostatic pressing to obtain a green embryo;

[0053] (B) Preform processing: according to the design size, the reaction plate blank is processed on a plane without processing microchannels; according to the design siz...

Embodiment 3

[0060] The silicon carbide micro-reaction assembly includes two reaction plates 1 (such as Figure 1-2 shown), the thickness of reaction plate 1 is 8 mm, the width of microchannel 2 is 0.8 mm, and the depth is 1 mm.

[0061] Ni-Fe-Cr-Mo Hastelloy foils with a thickness of 0.1 mm are used for welding between the two reaction plates 1 at a welding temperature of 1350 °C and a welding pressure of 30 bar.

[0062] The specific manufacturing steps are:

[0063] (A) Plain embryo forming: use silicon carbide to spray granulate powder, and directly isostatic pressing to obtain a green embryo;

[0064] (B) Elemental embryo processing: according to the design size, the reaction plate element embryos are processed in a plane, and the microchannels are not processed;

[0065] (C) High temperature sintering: the plate obtained in step (B) is sintered under vacuum micro-negative pressure, and the sintering conditions are: 2100°C-2150°C, 1 h;

[0066] (D) Reaction plate processing: The mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com