Production process method of needle coke

A production process, needle coke technology, applied in the field of needle coke production process, can solve the problems of narrow range of needle coke fractionation, high metal impurities, increased production costs of enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0023] A kind of production process method of needle coke provided by the invention, it comprises:

[0024] S1: a pretreatment step of needle coke raw material oil slurry;

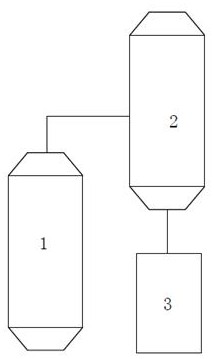

[0025] S2: heat treatment for the needle coke raw material oil slurry, and carry out distillation under negative pressure conditions, that is, by figure 1 The tank body 1 in the tank is subjected to negative pressure distillation, and then the initial stage oil, the middle stage oil and the heavy stage oil are obtained, and the middle stage oil is introduced into the needle coke forming tank 2;

[0026] S3: forming needle coke from the middle oil in the needle coke forming tank 2;

[0027] S4: Perform post-processing on the formed needle coke. The needle coke passes through the grinding structure 3 under the condition of flow, and forms powdery needle coke under the action of the grinding structure 3. At the same time, add adsorbent, adsorbent and powder needle coke The coke flows downstream in a mixed m...

no. 2 example

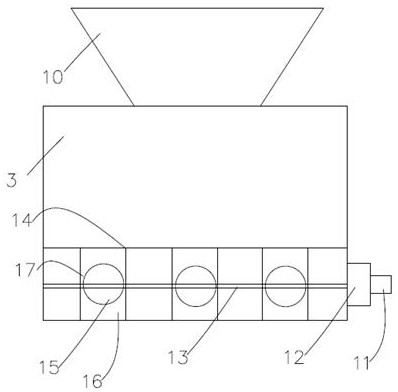

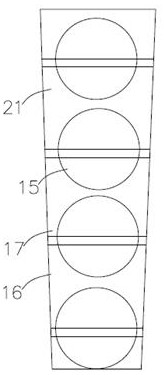

[0031] Preferably, as figure 2 As shown, the needle coke of this embodiment is added into the feeding hopper 10, and the grinding structure 3 is arranged under the feeding hopper 10. The grinding structure 3 includes a driving motor 11, a gear transmission structure 12, a rotating rod 13, a bottom plate 14 and a rotating sphere 15 , the rotating sphere 15 is rotatably arranged in the slot 16 of the bottom plate 14, the bottom plate 14 is located below the hopper 10, the rotating rod 13 passes through the bottom plate 14 transversely and is in contact with the bottom plate 14. The rotating sphere 15 is connected, and a gap 17 is formed between the rotating sphere 15 and the inner wall of the slot 16, and the gap 17 is used for the blanking of needle coke; the production process method includes the following steps: through the driving motor 11 provides power, and the gear transmission structure 12 transmits the power to the rotating rod 13. When the rotating rod 13 rotates, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com