Process for reducing fabric hairiness shedding, fuzzing and pilling

A pilling and crafting technology, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, textiles, etc., can solve the problems of pilling, pilling, etc., and achieve the improvement of pilling and pilling, Reduces lint and pilling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

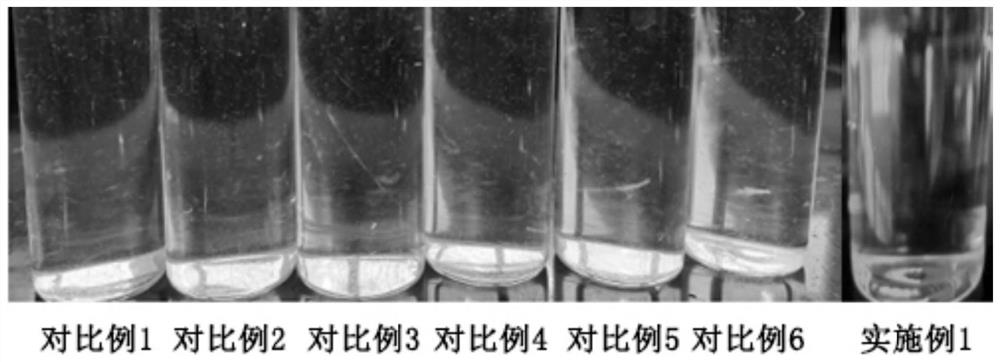

Embodiment 1

[0029] A hemp woven fabric with a weave specification of H14×14 52×45, spinning, weaving, pre-treatment and finishing according to the weave specification, wherein the spinning sequence includes blowing and carding, combing, drawing, roving, Spinning and winding process, winding into yarn, adding 5% polyethylene staple fiber in the process of carding fibers in the blowing and carding process;

[0030] After the yarn is slashed, it is passed through the woven fabric according to the weave specification;

[0031] The pre-treatment method of enzyme retreat and oxygen bleaching is used to remove the size and natural impurities on the surface of the yarn, so that the fabric has hair effect (more than 2.5cm hair effect in warp and weft direction in 1 minute) and strength (grasp in warp and weft direction) sample strength above 150N);

[0032] The pre-treated fabric was baked at 140°C for 2 minutes, and after finishing, the H14×14 52×45 fabric was obtained.

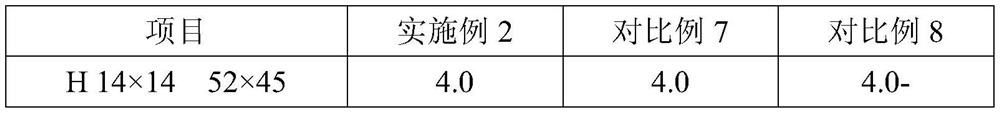

Embodiment 2

[0046] Prepare H14×14 52×45 fabric, C 24×2472×60 fabric, T / C 26×26 100×50 fabric and B40×C20 133×47 fabric in the order of spinning, weaving, pretreatment and finishing , wherein 5% corn short fiber is added in the process of carding fibers in the cleaning and carding process. After cleaning and carding, the corn fiber content is tested according to the detection method in the national standard GB / T 2910 to be 5% ± 0.5%, and then the synthetic method is carried out. Yarn, spinning and weaving process, and pretreatment, dyeing, finishing, wherein the baking condition of finishing is 150 ℃, 3min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com