Novel vertical titanium alloy micro-channel inner spiral tube-sheet heat exchanger

A technology of plate heat exchangers and inner spiral tubes, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of lack of low-temperature toughness and fracture toughness, inability to apply to various small spaces, and price fluctuations Larger problems, to achieve the effect of increasing high pressure resistance, reducing leakage of working fluid, and increasing overall structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. All other embodiments obtained by persons of ordinary skill in the art based on the embodiments of the present invention belong to the protection scope of the present invention.

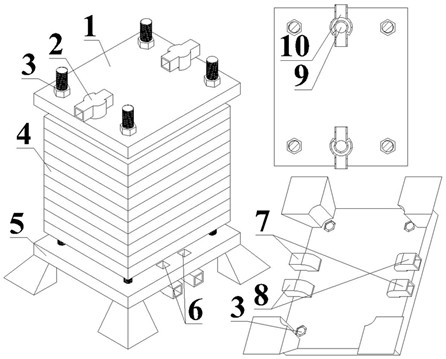

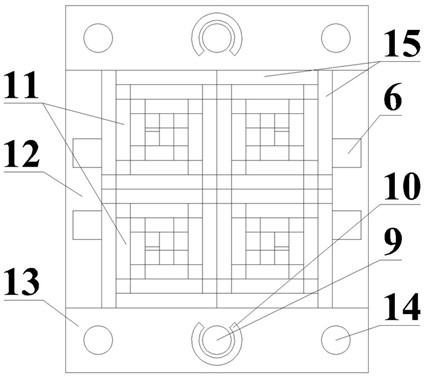

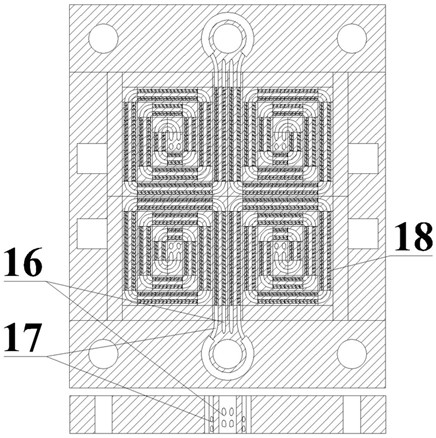

[0022] figure 1 It is a schematic structural diagram of a vertical titanium alloy microchannel plate heat exchanger provided by an embodiment of the present invention. Such as figure 1 As shown, the heat exchanger is provided with a symmetrical inflow casing conduit 2 that runs through the top pressure plate 1 and all heat exchange plates 4, and the four corners of the whole are provided with double-headed clamping bolt perforations 14, which are reinforced by double-headed clamping bolts 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com