C3 liquid phase hydrogenation reactor online prediction automatic control method and system

A hydrogenation reactor and liquid-phase hydrogenation technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of low efficiency of C3 hydrogenation reaction, and achieve the effect of maximizing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

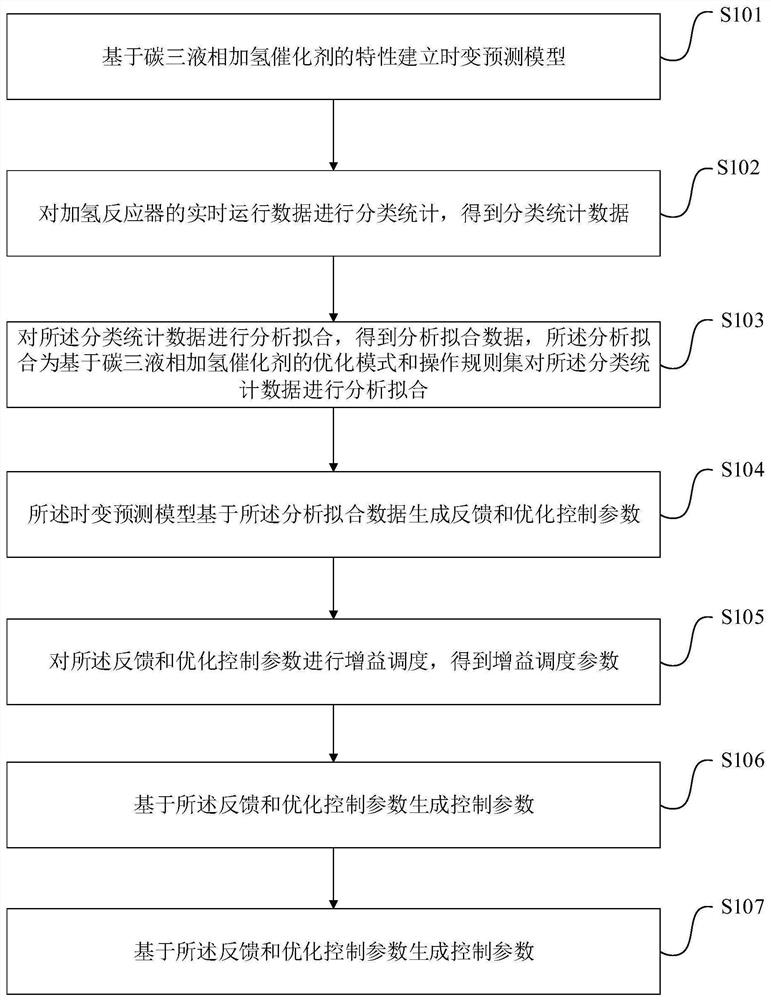

[0077] like figure 1 As shown, a carbon three-phase liquid-phase hydrogenation reactor online predictive automatic control method, including:

[0078] Step S101: Establish a time-varying prediction model based on the characteristics of the carbon three-liquid-phase hydrogenation catalyst;

[0079] Step S102: Carry out classified statistics on the real-time operation data of the hydrogenation reactor to obtain classified statistical data;

[0080] The real-time operation data is based on the user's operation of the hydrogenation reactor. Specifically, it includes the composition and content of materials before and after the C3 liquid phase hydrogenation reactor, the composition and content of the top of the depropanizer tower or the composition and content of the bottom of the deethanizer tower, the composition and content of the circulating C3 material, the online running time of the catalyst, the material Changes in flow rate, reaction temperature, pressure, hydrogen, carbo...

Embodiment 2

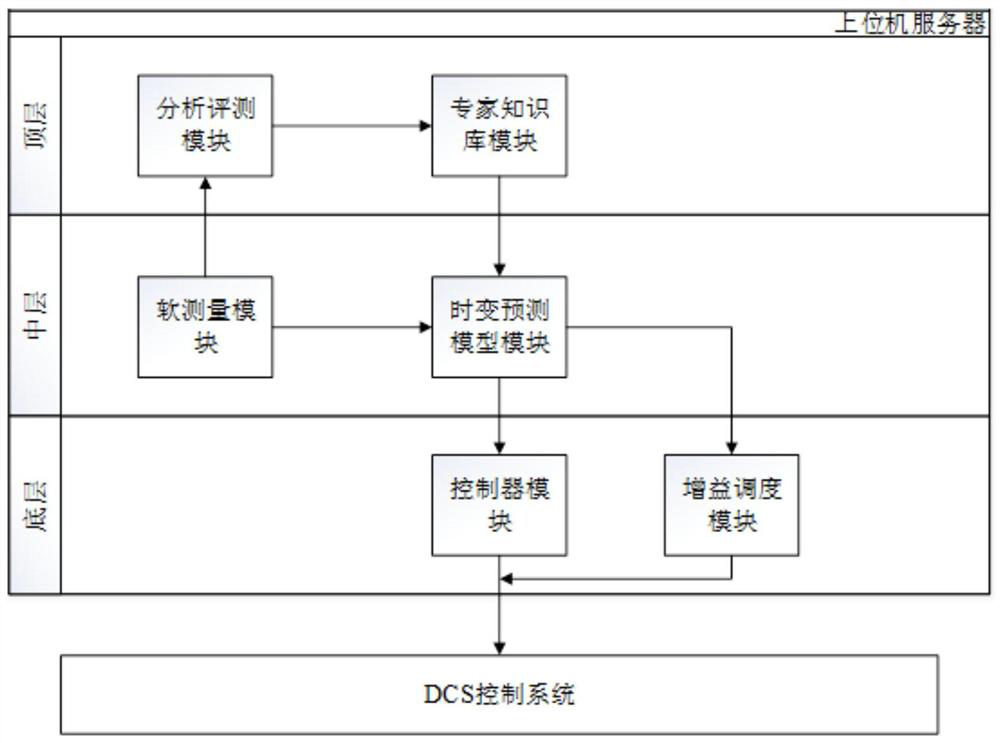

[0134] like image 3 As shown, an online prediction automatic control system for a carbon three-phase liquid-phase hydrogenation reactor includes: a time-varying prediction model module, an expert knowledge base module, a gain scheduling module, a soft sensor module, an analysis and evaluation module and a controller module;

[0135] The time-varying prediction model module is used to establish a time-varying prediction model based on the characteristics of the carbon three-liquid phase hydrogenation catalyst, and generate feedback and optimize control parameters based on the time-varying prediction model and analysis and fitting data

[0136] The soft measurement module and the analysis and evaluation module are used to carry out classified statistics to the real-time operation data of the hydrogenation reactor to obtain classified statistical data;

[0137] The expert knowledge base module is used to analyze and fit the classified statistical data to obtain the analysis and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap