Metal organic framework and covalent organic framework composite membrane and preparation and application thereof

A technology of covalent organic framework and metal organic framework, applied in the field of composite membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

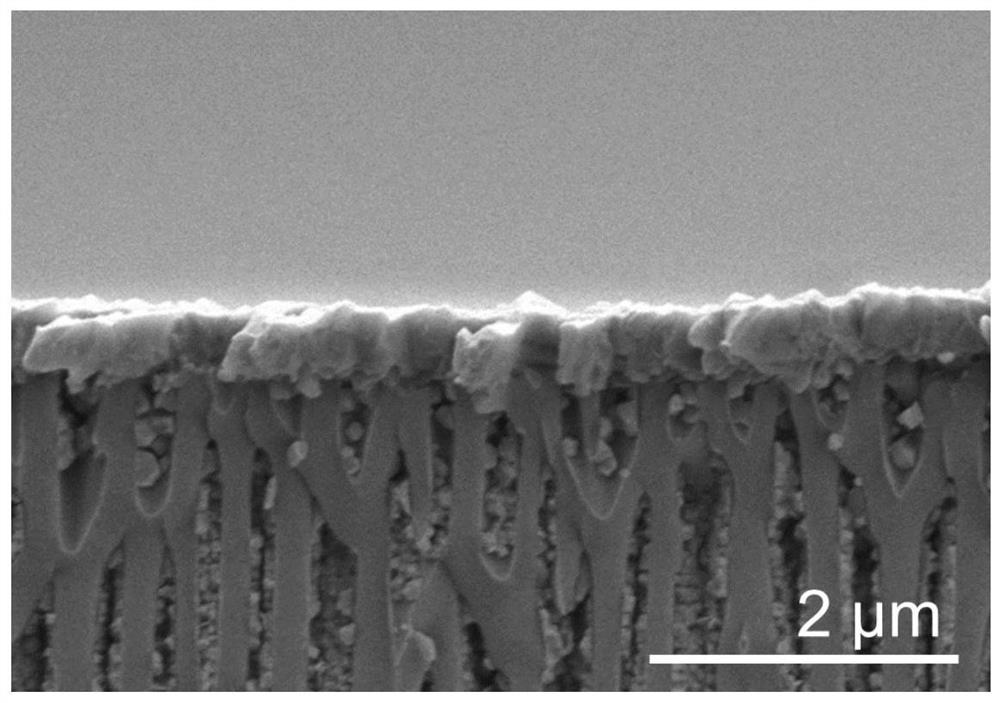

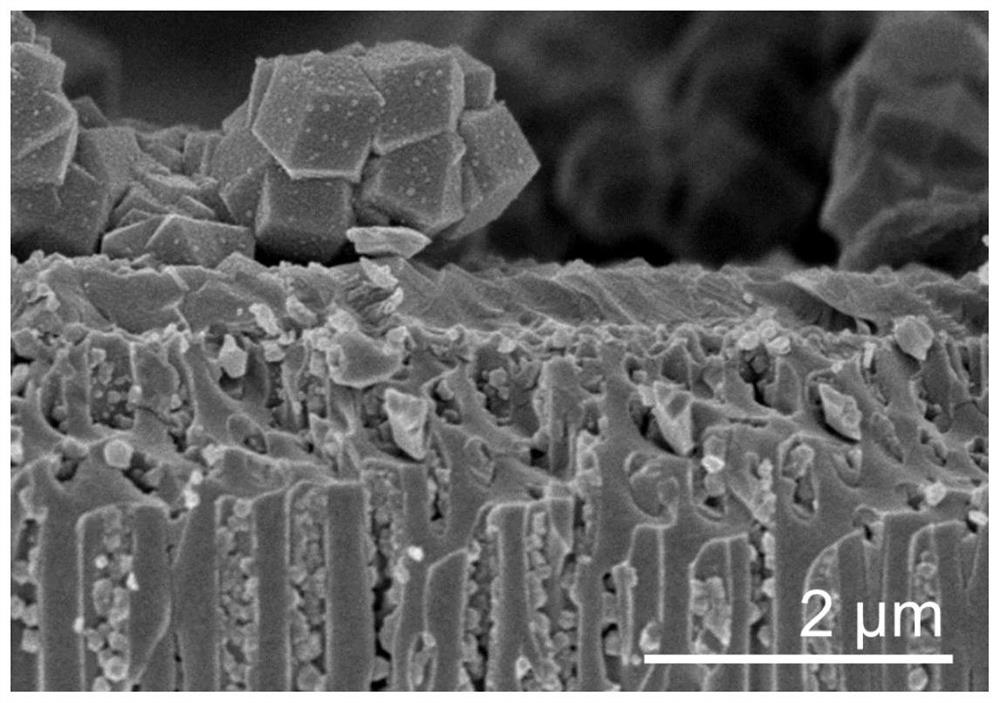

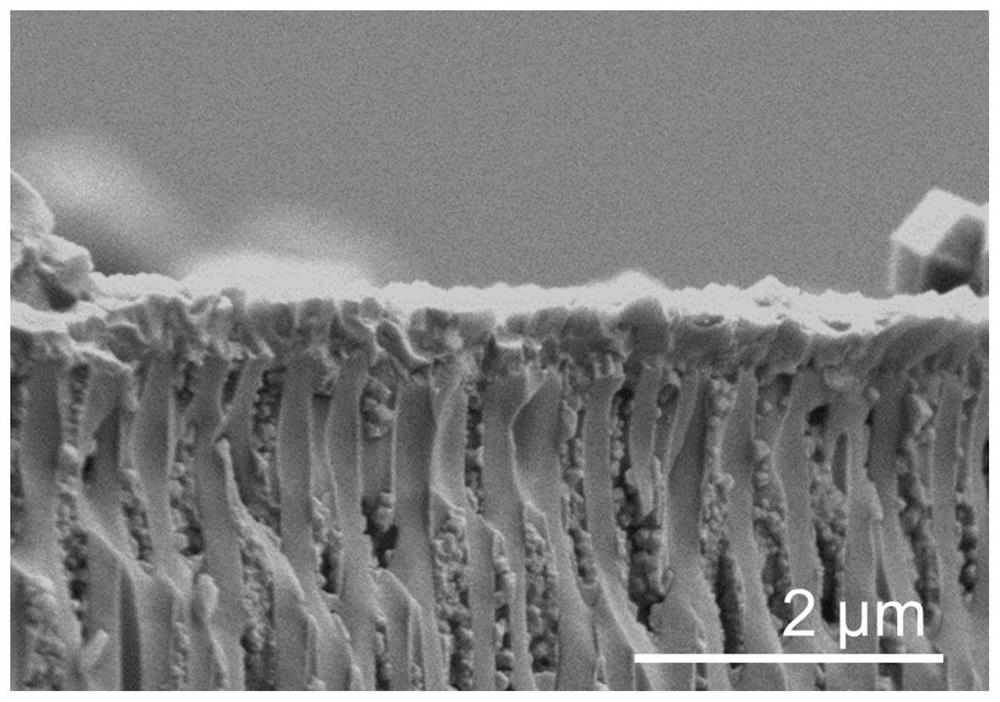

[0015] Embodiment 1, prepare MOF-COF composite film, the steps are as follows:

[0016] Step 1, preparation of EBCOF nanosheets by interfacial polymerization:

[0017] Dissolve 0.1 mmol of trialdehydephloroglucinol (TP) in 130 mL of dichloromethane. Then 80 mL of deionized water was added to the surface of the Tp solution as a buffer layer. Finally, 0.15 mmol of ethidium bromide (EB) and 0.3 mmol of p-toluenesulfonic acid (PTSA) were dissolved in 130 mL of water and slowly added on top of the aqueous buffer layer. The system was maintained at 30°C for 10 days under undisturbed conditions. Collect the two-dimensional sheets formed at the interface (with a lateral dimension of 5-30 μm and a thickness of about 3 nm), and dialyze with deionized water for 3 days to obtain two-dimensional cationic EBCOF nanosheets.

[0018] Step 2. Preparation of MOF-COF composite film by co-deposition method:

[0019] Anodized aluminum oxide (AAO) was used as the base film, and the surface of A...

Embodiment 2

[0021] Example 2, preparation of MOF-COF composite membrane, the preparation process of this example is basically the same as that of Example 1, the only difference is that in step 2, the mass of EBCOF nanosheets added to the co-deposition solution is changed from 0.2mg to 0.6mg (that is, the relative mass of EBCOF nanosheets and 2-methylimidazole is 1.46×10 -4 ) to obtain a MOF-COF composite film with a thickness of about 360 nm, which is designated as film 2.

[0022] Use membrane 2 for C 3 h 6 / C 3 h 8 System separation, under the conditions of 25°C and feed gas pressure 1bar, C 3 h 6 Penetration rate is 168GPU, C 3 h 6 / C 3 h 8 The selectivity is 203.

Embodiment 3

[0023]Example 3, preparation of MOF-COF composite film, the preparation process of this example is basically the same as that of Example 1, the only difference is that in step 2, the mass of EBCOF nanosheets added to the co-deposition solution is changed from 0.2 mg to 0.8mg (that is, the relative mass of EBCOF nanosheets and 2-methylimidazole is 1.95×10 -4 ) to obtain a MOF-COF composite film with a thickness of about 360 nm, which is denoted as film 3.

[0024] Use membrane 3 for C 3 h 6 / C 3 h 8 System separation, under the conditions of 25°C and feed gas pressure 1bar, C 3 h 6 Penetration rate is 110GPU, C 3 h 6 / C 3 h 8 The selectivity is 136.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com