Device and method for deeply denitrifying landfill leachate based on in-situ induction of short-cut denitrification coupled anaerobic ammonia oxidation of sludge fermentation liquor

An anaerobic ammonia oxidation and landfill leachate technology, which is applied in the field of biological denitrification of low-carbon-nitrogen ratio and high-ammonia-nitrogen wastewater and combined treatment of excess sludge, can solve the problem that the denitrification efficiency of late leachate cannot be improved, and increase the denitrification of landfill leachate. cost, inability to deal with landfill leachate economically and efficiently, to achieve the effect of saving aeration energy consumption, reducing operation and construction costs, and facilitating operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

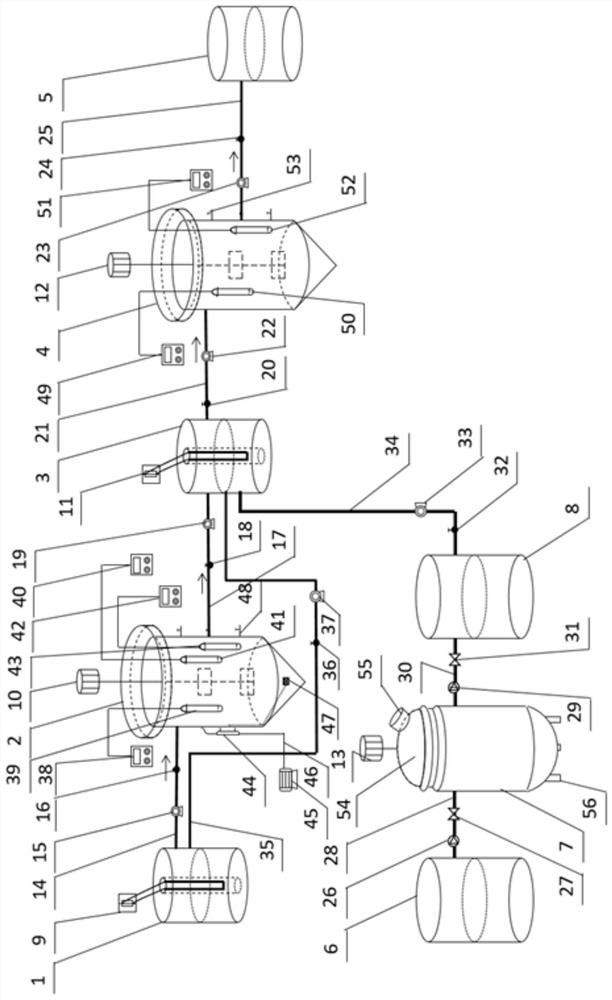

[0032] The denitrification system and operation method involved in the present invention will be further described below in conjunction with the accompanying drawings:

[0033] As shown in the accompanying drawings of the description, a device for deep denitrification of landfill leachate based on in-situ induction of short-range denitrification coupled with anaerobic ammonia oxidation of sludge fermentation liquid, is characterized in that: landfill leachate raw water tank (1), short-range nitrification SBR reactor (2), intermediate water tank (3), inlet sludge storage tank (6), sludge fermentation tank (7), sludge discharge storage tank (8), anaerobic ammonium oxidation reactor (4), outlet tank ( 5). A first temperature-controlled heating device (9) is arranged in the middle of the leachate raw water tank (1), and the leachate raw water tank (1) passes through the first water inlet pipe (14) and the first peristaltic pump (15) and the short-path nitrification SBR reactor ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com