Novel thermal barrier coating structure and preparation method thereof

A thermal barrier coating, a new type of technology, applied in coatings, metal material coating processes, manufacturing tools, etc., can solve problems such as complex processes, unsuitable high-temperature blades, low precision, etc., and achieve the effect of improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The DD6 alloy substrate is cut into a standard sample with a diameter of 25.4cm by wire cutting process, and then the surface is ground, polished, cleaned with acetone, cleaned with alcohol and dried; then the surface is strengthened by YAG nanosecond pulse laser, The absorbing layer is aluminum foil, and the constraining layer is water. The process parameters are as follows: the pulse width is 10 ns, the energy is 5 J, the spot diameter is 3 mm, the overlap rate is 40%, and the impact is 5 times. The thickness of the impact-strengthened layer obtained is 40 μm. .

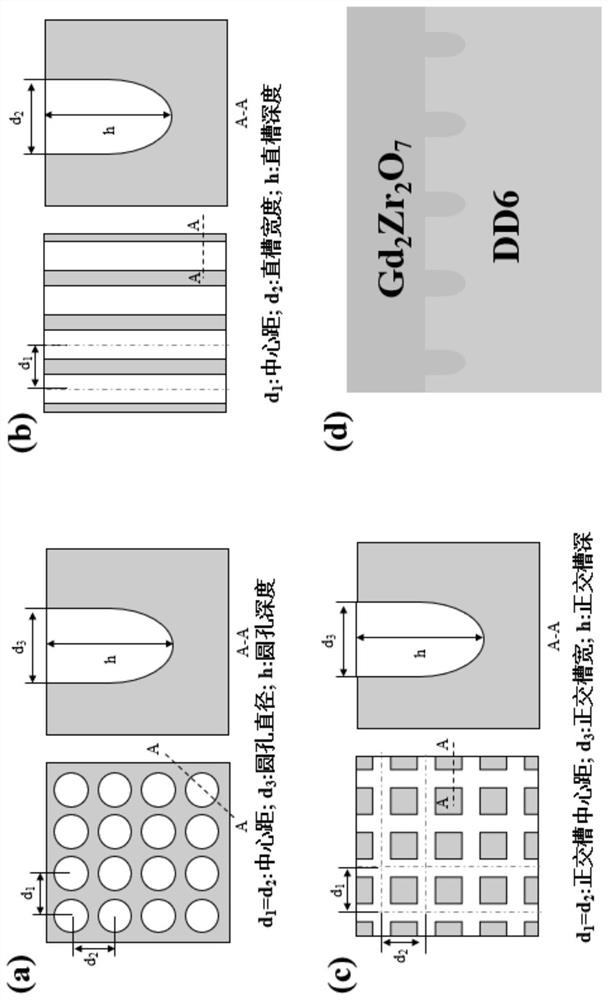

[0021] The samples after laser shock strengthening were ultrasonically cleaned in acetone and alcohol for 30 minutes respectively to remove surface grease pollutants, and then dried in a drying oven at 80°C for 30 minutes. A picosecond laser is used to construct micro-textures on its surface. The process parameters of the picosecond laser are: pulse width 13ps, repetition frequency 500kHz, scanning speed 40...

Embodiment 2

[0026] The DD6 alloy substrate is cut into a standard sample with a diameter of 25.4cm by wire cutting process, and then the surface is ground, polished, cleaned with acetone, cleaned with alcohol and dried; then the surface is strengthened by YAG nanosecond pulse laser, The absorbing layer is aluminum foil, and the constraining layer is water. The process parameters are as follows: the pulse width is 10 ns, the energy is 5 J, the spot diameter is 3 mm, the overlap rate is 40%, and the impact is 5 times. The thickness of the impact-strengthened layer obtained is 40 μm. .

[0027] The laser-shocked sample was ultrasonically cleaned with acetone and alcohol for 30 minutes to remove surface grease pollutants, and then dried in a drying oven at 80°C for 30 minutes. A picosecond laser is used to construct micro-textures on its surface. The process parameters of the picosecond laser are: pulse width 13ps, repetition frequency 500kHz, scanning speed 400mm / s, number of repetitions 10...

Embodiment 3

[0032] The DD6 alloy substrate is cut into a standard sample with a diameter of 25.4cm by wire cutting process, and then the surface is ground, polished, cleaned with acetone, cleaned with alcohol and dried; then the surface is strengthened by YAG nanosecond pulse laser, The absorbing layer is aluminum foil, and the constraining layer is water. The process parameters are as follows: the pulse width is 10 ns, the energy is 5 J, the spot diameter is 3 mm, the overlap rate is 40%, and the impact is 5 times. The thickness of the impact-strengthened layer obtained is 40 μm. .

[0033] The laser-shocked sample was ultrasonically cleaned with acetone and alcohol for 30 minutes to remove surface grease pollutants, and then dried in a drying oven at 80°C for 30 minutes. A picosecond laser is used to construct micro-textures on its surface. The process parameters of the picosecond laser are: pulse width 13ps, repetition frequency 500kHz, scanning speed 400mm / s, number of repetitions 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com