Graphene anion regenerated cellulose composite fiber and preparation method thereof

A technology of regenerated cellulose and composite fibers, applied in the direction of single-component cellulose rayon, fiber chemical characteristics, wet spinning method, etc., which can solve the application limitations of cellulose fibers, the functionality is not washable, and has no functionality and other problems, to achieve the effect of excellent antibacterial performance, low cost and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

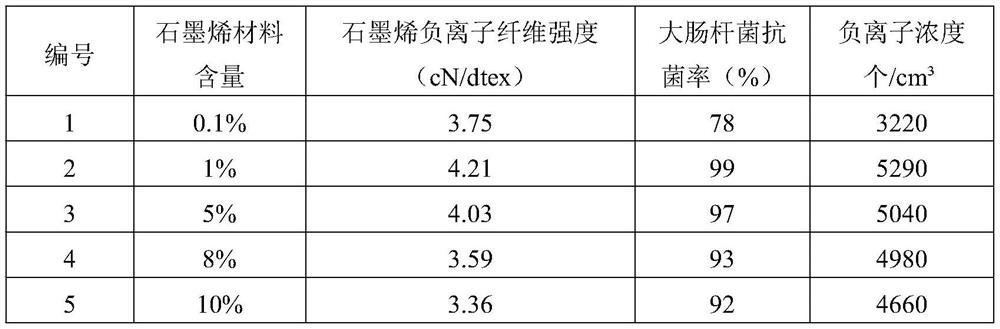

Examples

Embodiment 1

[0036] A preparation method of graphene negative ion regenerated cellulose composite fiber, which comprises:

[0037] Step 1, weighing each raw material in proportion; the raw material includes cellulose, graphene material, modifier, negative ion powder.

[0038] Preferably, the raw material contains 99% of cellulose, 0.1% of graphene material, 0.4% of modifying agent and 0.5% of negative ion powder in terms of mass percentage.

[0039] The modifier is a surfactant, which is obtained by mixing polyethylene glycol, polyvinylpyrrolidone, and hydroxymethyl cellulose in a mass ratio of 1:1:2.

[0040] The graphene material is graphene prepared by a mechanical exfoliation method.

[0041] Negative ion powder is tourmaline powder.

[0042] Step 2, use a ball mill to grind the negative ion powder to a particle size of less than 1 μm, and then dry it.

[0043] Step 3, disperse the cellulose, graphene, and modifier in the NMMO aqueous solution, and fully stir with a mixer for 50-100...

Embodiment 2

[0049] A preparation method of graphene negative ion regenerated cellulose composite fiber, which comprises:

[0050] Step 1, weighing each raw material in proportion; the raw material includes cellulose, graphene material, modifier, negative ion powder.

[0051] Preferably, the raw material contains 93.9% of cellulose, 1% of graphene material, 0.1% of modifying agent and 5% of negative ion powder in terms of mass percentage.

[0052] The modifier is a surfactant, which is obtained by mixing polyethylene glycol, polyvinylpyrrolidone, and hydroxymethyl cellulose in a mass ratio of 1:2:2.

[0053] The graphene material is graphene oxide prepared by mechanical exfoliation.

[0054] Negative ion powder is rare earth element powder.

[0055] Step 2, use a ball mill to grind the negative ion powder to a particle size of less than 1 μm, and then dry it.

[0056] Step 3, disperse the cellulose, graphene, and modifier in the NMMO aqueous solution, and fully stir with a mixer for 50-...

Embodiment 3

[0062] A preparation method of graphene negative ion regenerated cellulose composite fiber, which comprises:

[0063] Step 1, weighing each raw material in proportion; the raw material includes cellulose, graphene material, modifier, negative ion powder.

[0064] Preferably, the raw material comprises 89% of cellulose, 5% of graphene material, 5% of modifying agent and 1% of negative ion powder by mass percentage in the raw material.

[0065] The modifier is a surfactant, which is obtained by mixing polyethylene glycol, polyvinylpyrrolidone, and hydroxymethyl cellulose in a mass ratio of 1:2:3.

[0066] The graphene material is graphene prepared by chemical vapor deposition.

[0067] Negative ion powder is tourmaline and rare earth element powder.

[0068] Step 2, use a ball mill to grind the negative ion powder to a particle size of less than 1 μm, and then dry it.

[0069] Step 3, disperse the cellulose, graphene, and modifier in the NMMO aqueous solution, and fully stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com