Uniform powder coating device for cable production

A uniform and cable technology, which is applied in the field of uniform powder coating device for cable production, can solve problems such as product quality impact, and achieve the effects of improving coating effect, saving cost and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

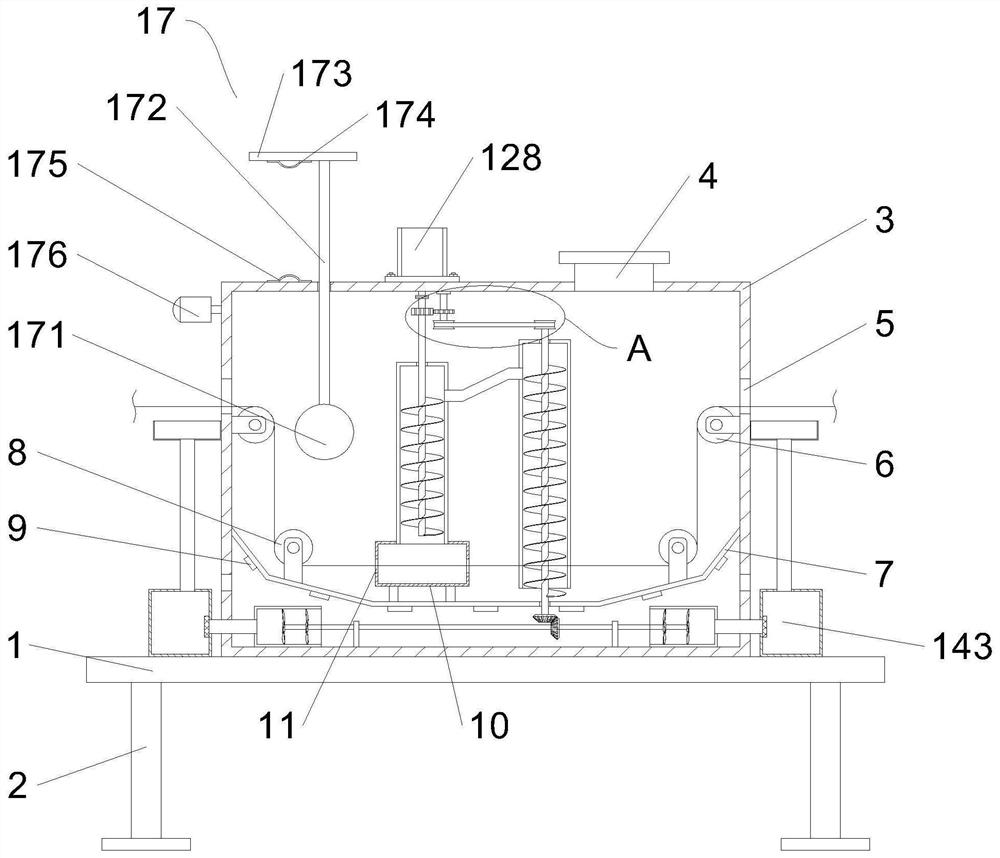

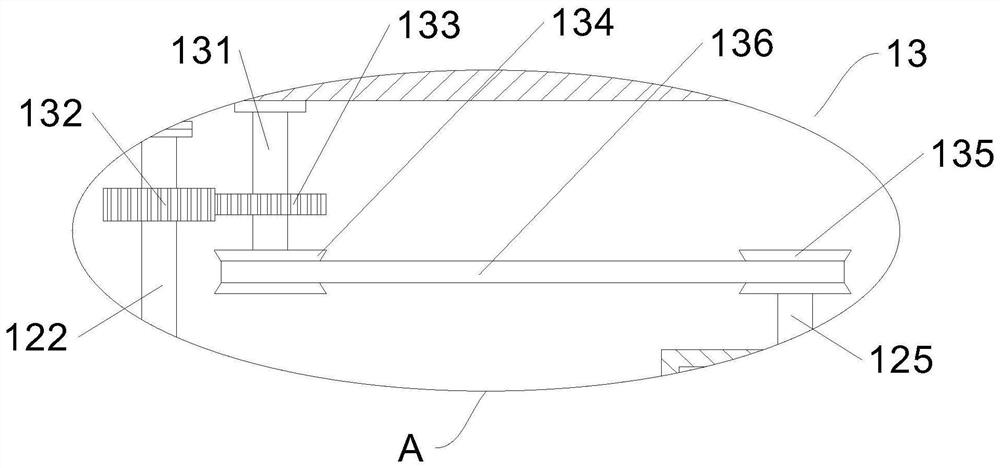

[0030] In this embodiment, as shown in Figures 1-5, a uniform powder coating device for cable production includes a workbench 1, and support legs 2 are fixed at the four corners of the bottom end of the workbench 1. A box body 3 is fixed in the middle part of the top of the workbench 1, and the box body 3 is provided with a side door, and a visible window is arranged on the side door. The upper part of the two side walls is symmetrically provided with a through groove 5, and the two side walls of the box body 3 are positioned at the lower side of the through groove 5 and are symmetrically equipped with a guide wheel 1-6, and the lower part of the inner wall of the box body 3 is fixed with a folded plate 7, the folded plate Two guide wheels 8 are installed symmetrically on both sides of the top of 7, and the horizontal section of the folding plate 7 is fixed with an extruding shell 10, and the two ends of the extruding shell 10 are symmetrically provided with a port 11, and the ...

Embodiment 2

[0033]On the basis of Embodiment 1, a plurality of electric heating blocks 9 are uniformly fixed on the bottom end of the folded plate 7 . Through the above method, the electric heating block 9 works, heats the folding plate 7, and then heats the talcum powder, so as to prevent the talcum powder from absorbing water and agglomerating due to moisture, and ensures the wrapping effect of the talcum powder on the cable.

Embodiment 3

[0035] On the basis of Embodiment 2, the recovery mechanism 14 includes a suction hood 141 symmetrically fixed on the lower side of the through groove 5 at the outer end of the box body 3, and the bottom ends of the two suction hoods 141 are connected and installed with vertical The suction pipe 142, the bottom ends of the two suction pipes 142 are connected with a storage box 143, the storage box 143 is provided with a side door, the inner ends of the two storage boxes 143 are connected with an air induction pipe 145, and the two A filter screen 144 is fixed on the inner wall of the storage box 143 corresponding to the position of the air induction pipe 145. The inner ends of the two air induction pipes 145 run through the box body 3 and are connected with a cylinder body 146. The bottom wall of the box body 3 is connected by rotation through a support block. There is a round rod 149 in the horizontal direction, the round rod 149 is connected to the second rotating shaft 125 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com