Catalyst composition and method for preparing polyisobutene by using same

A polyisobutylene and catalyst technology, applied in the field of polyisobutylene preparation, can solve the problems of corrosion, product quality deterioration, difficult treatment, etc., and achieve the effect of solving a large amount of waste water and excellent polymerization conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of polyisobutylene

[0065] The method for producing polyisobutene of the present invention is characterized by comprising the step of polymerizing isobutene in the presence of the catalyst composition.

[0066] In the present invention, the polymerization of isobutylene can be carried out at 10°C to 50°C, specifically above 10°C, above 15°C, above 25°C, and below 50°C, below 40°C, below 35°C, for example at 30°C.

[0067] If the polymerization temperature is above 0°C, appropriate catalyst activity can be obtained, the polymerization conversion rate can be shown to be excellent, and a small amount of catalyst can be used, while if the polymerization temperature is below 50°C, the chain transfer reaction can be controlled, the molecular weight of polyisobutylene and The exo content can be shown to be high and polyisobutylene with high quality can be produced.

[0068] In addition, the polymerization needs to meet the above temperature condition...

Embodiment

[0091] Hereinafter, the present invention will be described in more detail with reference to the embodiments. However, the following embodiments are only examples, and the scope of the present invention is not limited thereto.

[0092] Preparation of catalyst

preparation Embodiment 1

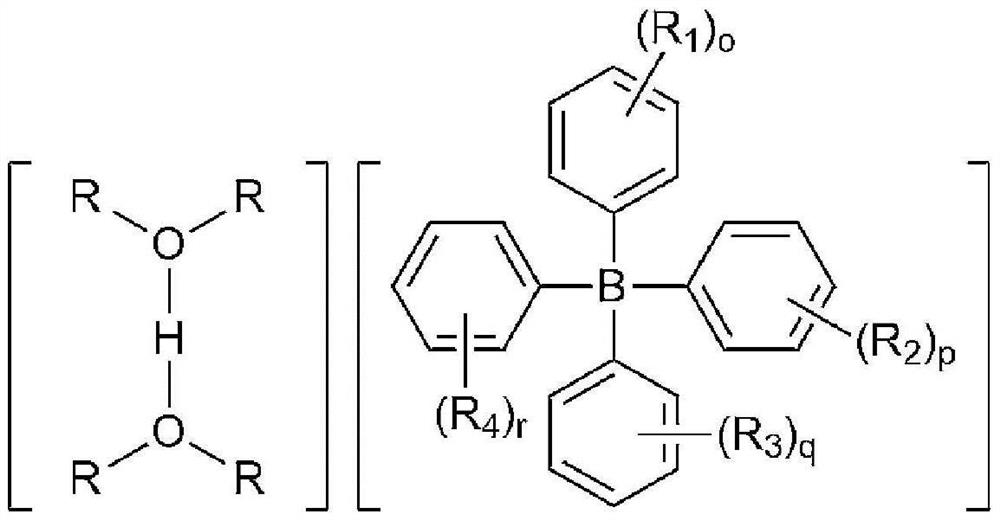

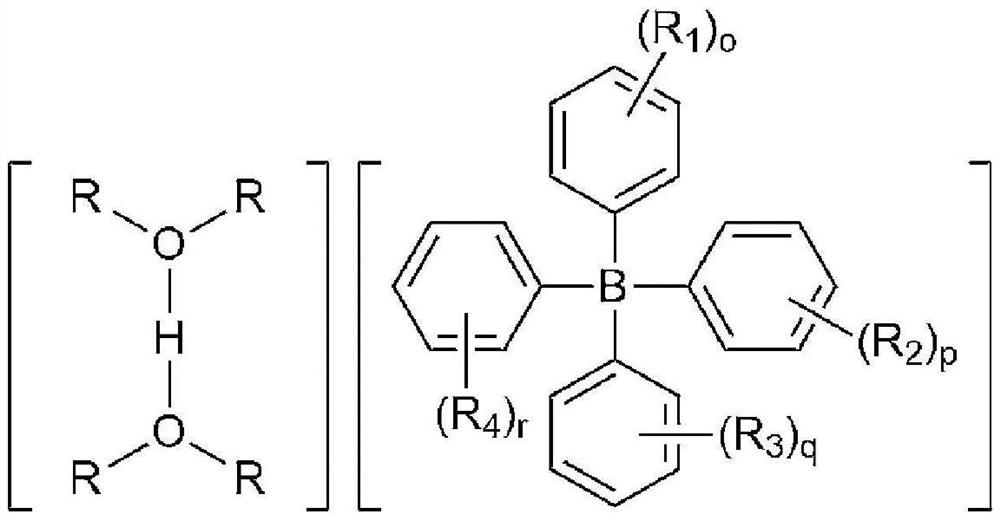

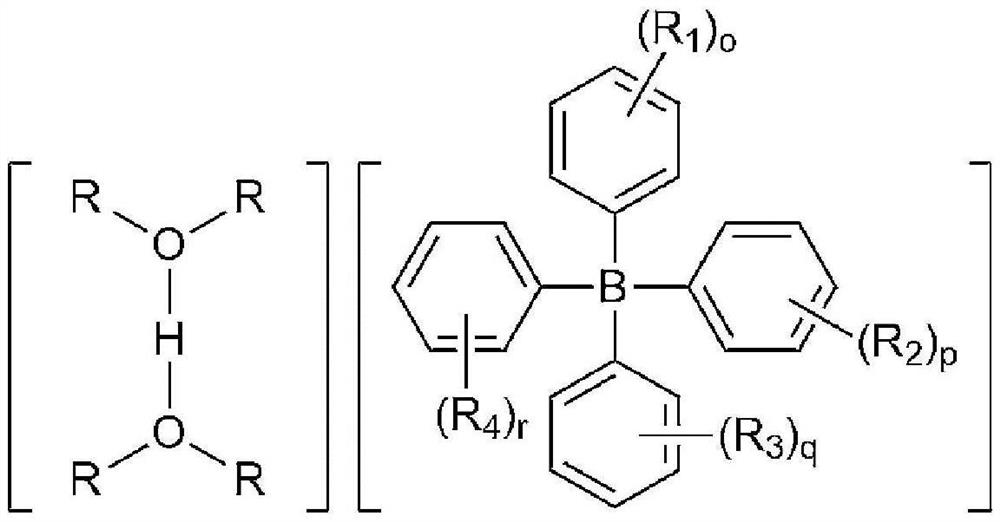

[0094] [Formula 1-1]

[0095]

[0096] In the glove box, 1 g of [H(Et 2 O) 2 ][B(C 6 f 5 ) 4] was added to a round bottom flask, and 10 mL of dichloromethane was added. At room temperature, 5 equivalents of anhydrous butyl ether (Sigma-Aldrich Co.) were added and stirred for 30 minutes. After stirring, all solvent was removed under vacuum. The white powder thus obtained was washed with anhydrous hexane by 5 mL x three times, and then dried again under vacuum to obtain [H(nBu 2 O) 2 ][B(C 6 f 5 ) 4 ].

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com