A device for synthesizing nitrogen oxides by air plasma

A plasma, nitrogen oxide technology, applied in nitrogen compounds, chemical/physical process, chemical/physical/physical chemical process, etc., can solve the limitation of plasma nitrogen fixation technology application, complicated discharge device fabrication, and inability to bring economic benefits and other problems, to achieve the effect of improving the generation efficiency, improving the nitrogen fixation efficiency and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

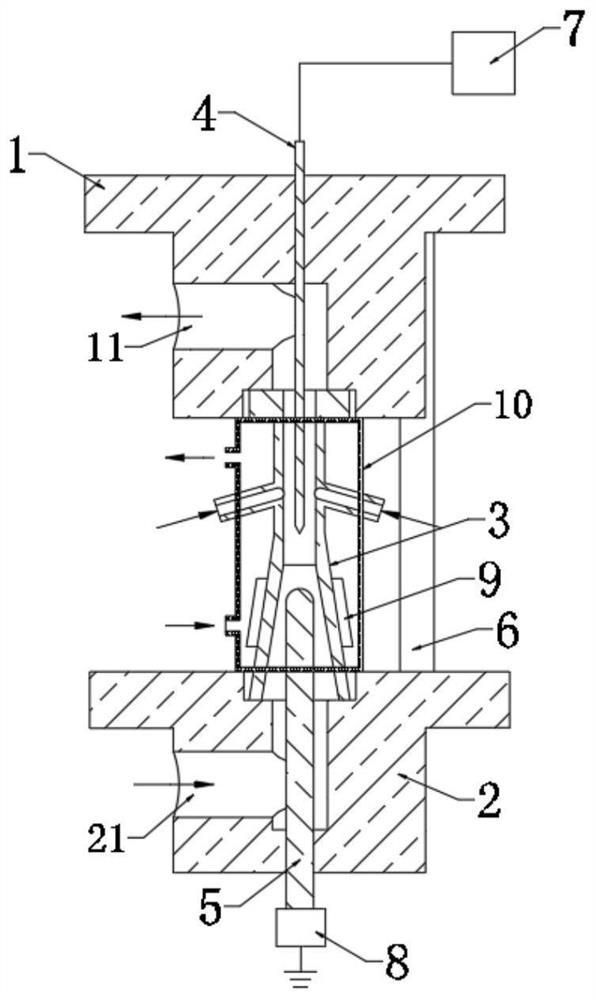

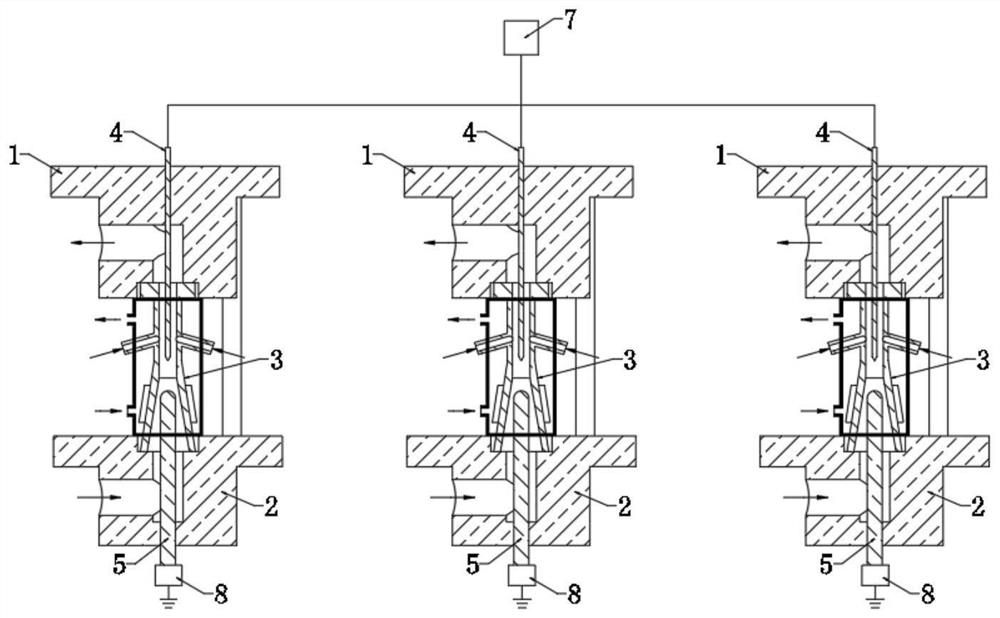

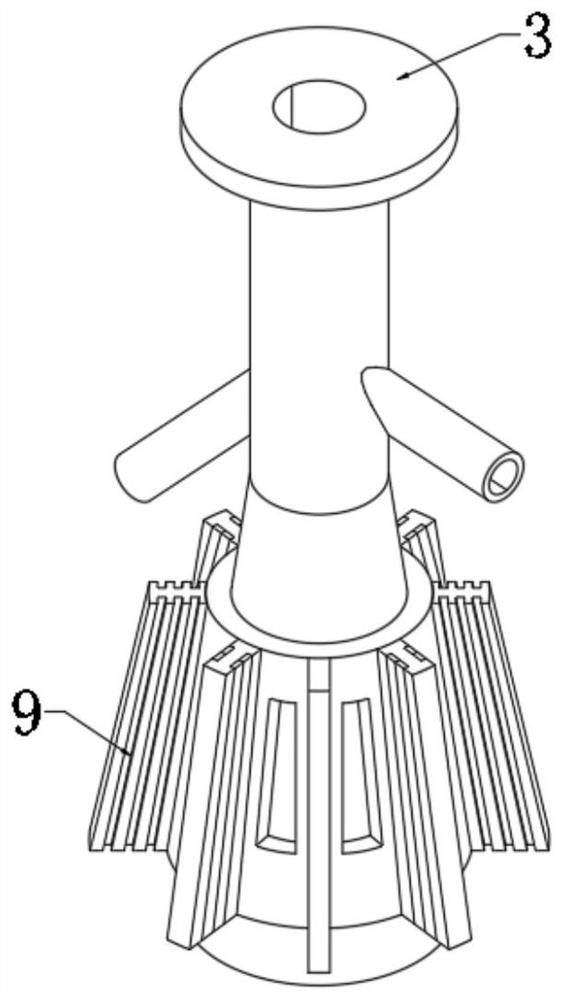

[0031] Such as figure 1 As shown, a device for synthesizing nitrogen oxides by air plasma is proposed in this embodiment, including a high-voltage end fixed block 1 and a grounded end fixed block 2, and a high-voltage electrode 4 is respectively fixed on the high-voltage end fixed block 1 and the grounded end fixed block 2 and the grounding electrode 5, the side of the high-voltage end fixing block 1 and the grounding end fixing block 2 are fixedly installed with the same dielectric tube 3, and the ends of the high-voltage electrode 4 and the grounding electrode 5 that are close to each other extend into the dielectric tube 3, and the medium The heat dissipation mechanism 9 and the cooling container 10 are fixedly set on the pipe 3, the displacement control platform 8 is fixedly installed on the bottom of the ground electrode 5, and the high voltage power supply 7, the high voltage electrode 4 and the high voltage power supply 7 are connected to one side of the high voltage end...

Embodiment 2

[0034] The high-voltage electrode 4 runs through the high-voltage end fixing block 1 and is fixedly connected with the high-voltage end fixing block 1 , and the ground electrode 5 runs through the grounding end fixing block 2 and is slidably connected with the grounding end fixing block 2 .

[0035] The sides of the high-voltage end fixing block 1 and the grounding end fixing block 2 are provided with threaded holes, and the inner threads of the two threaded holes are fixed with the same connecting bolt 6. The cooling container 10 is provided with a water inlet hole and a water outlet hole. The water inlet hole is located below the water outlet hole.

[0036] The high-voltage end fixing block 1 and the grounding end fixing block 2 are respectively provided with a high-pressure end gas inlet 11 and a grounding end gas inlet 21, and both the high-pressure end gas inlet 11 and the grounding end gas inlet 21 are connected to the medium pipe 3, The sides of the high-voltage end fix...

Embodiment 3

[0043] Such as Figure 6 As shown, the difference from Embodiment 1 lies in that the shape of the medium pipe 3 is adjusted, and the internal apertures are the same, making it more convenient to manufacture and lower in cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com