Polycrystalline silicon ingot squaring size adjustable ingot platform and using method

A polycrystalline silicon ingot, adjustable technology, applied in the direction of manufacturing tools, fine working devices, working accessories, etc., to achieve the effect of improving flexibility, increasing processing range, and improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

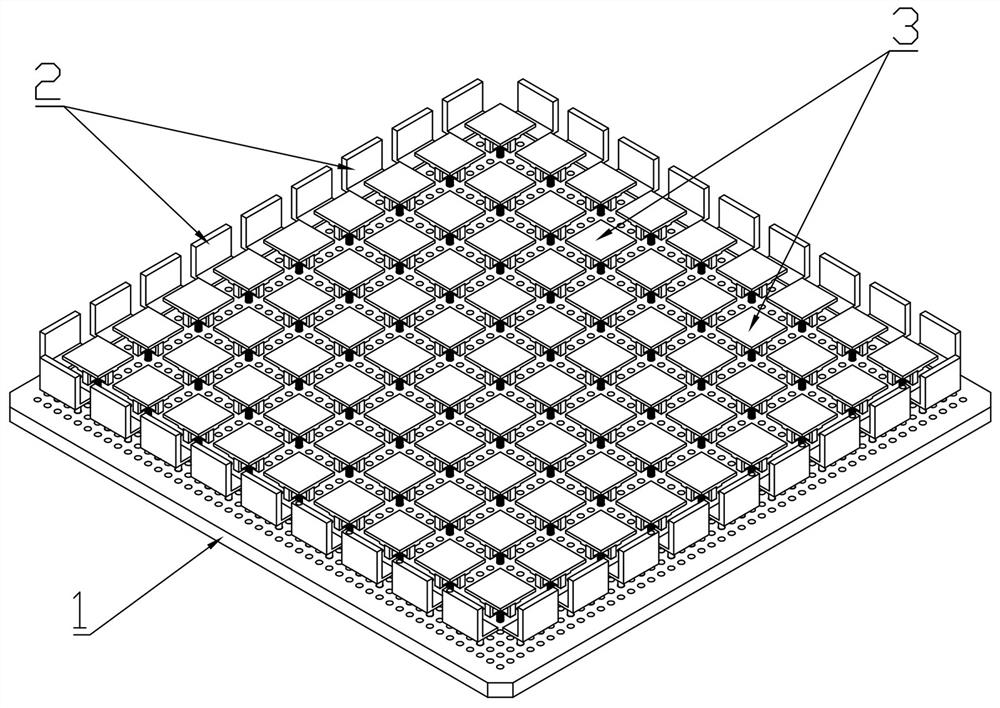

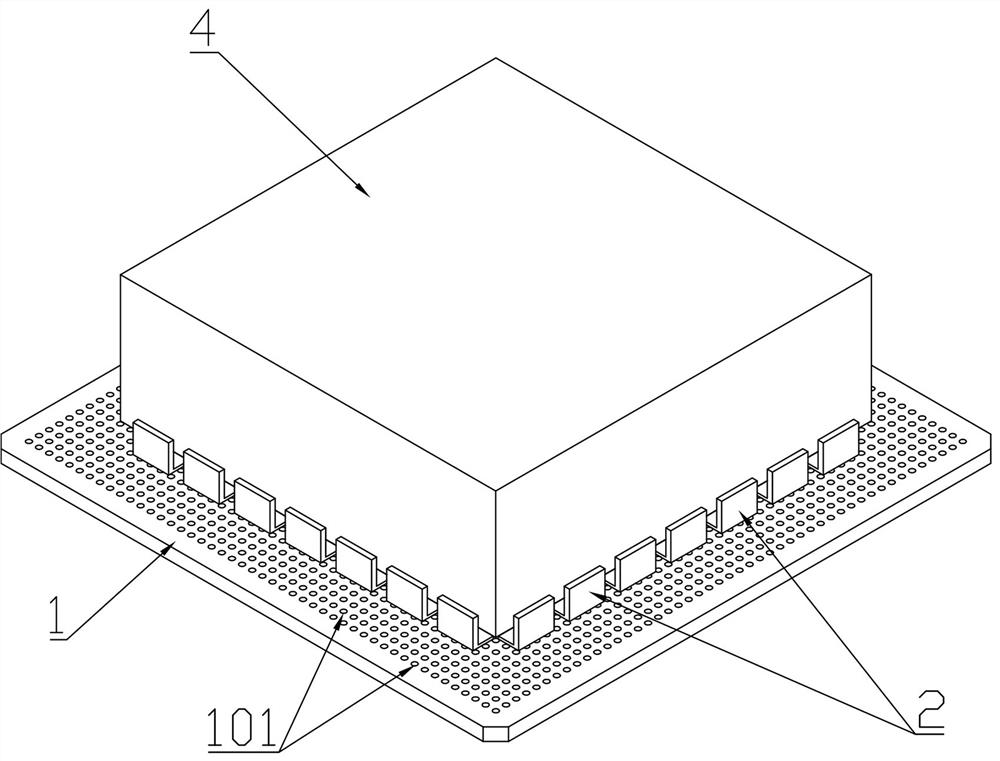

[0032] Implementation case 1: The single side length of a polysilicon block is 200mm, and the single processing quantity is 49 polysilicon blocks:

[0033] Step 1: Open installation holes 101 on the adjustment base plate 1, the distance between the installation holes 101 is set to 30mm, and the distance between the centers of the longitudinal holes and the centers of the transverse holes of the installation holes 101 is equal.

[0034] Step 2: In order to prevent the silicon powder generated during the subsequent cutting of the polysilicon ingot 4 from clogging the installation hole 101, a layer of plastic film should be laid on the surface of the adjustment base plate 1 after the opening of the hole is completed.

[0035] Step 3: According to the size of the polysilicon ingot 4 to be cut, take the installation hole 101 at the center of the adjustment base plate 1 as the symmetrical center, and arrange the crystal adjustment bases 3 in a matrix of 7*7 on the adjustment base pla...

Embodiment example 2

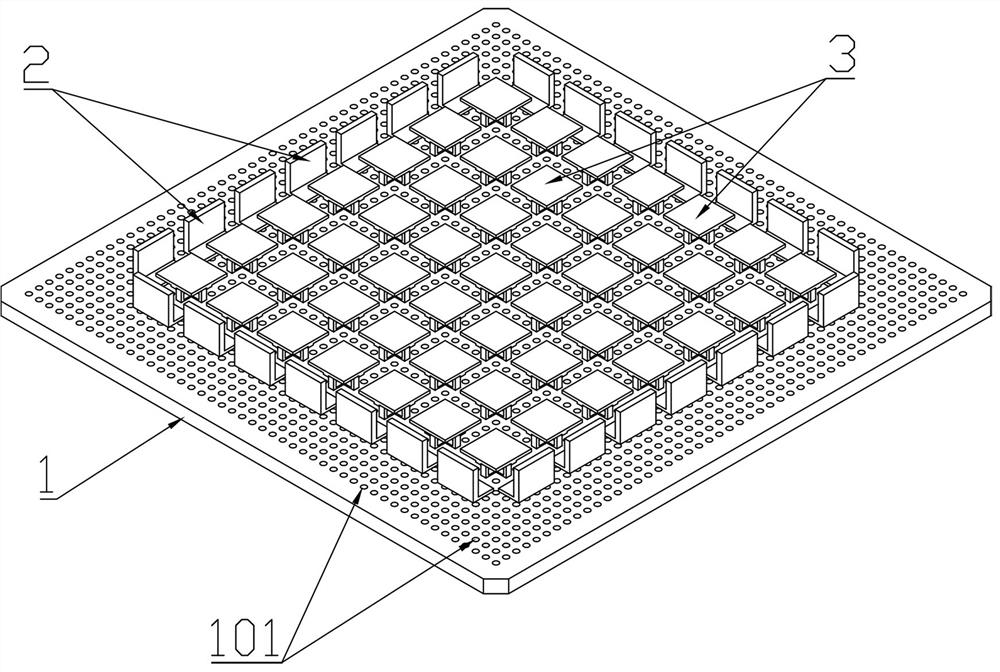

[0040] Implementation case 2: Production of polysilicon blocks with a single side length of 300 mm and a single processing quantity of 36 polysilicon blocks:

[0041] Step 1: Open installation holes 101 on the adjustment base plate 1, the distance between the installation holes 101 is set to 30mm, and the center distance between the longitudinal holes and the transverse holes of the installation holes 101 is equal.

[0042] Step 2: In order to prevent the silicon powder generated during the subsequent cutting of the polysilicon ingot 4 from clogging the installation hole 101, a layer of plastic film should be laid on the surface of the adjustment base plate 1 after the opening of the hole is completed.

[0043] Step 3: According to the size of the polysilicon ingot 4 to be cut, take the installation hole 101 at the center of the adjustment base plate 1 as the symmetrical center, and let the crystal adjustment base 3 be arranged in a matrix of 6*6 on the adjustment base plate 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com