Flexible composite film with high sensitivity and wide sensing range and application thereof

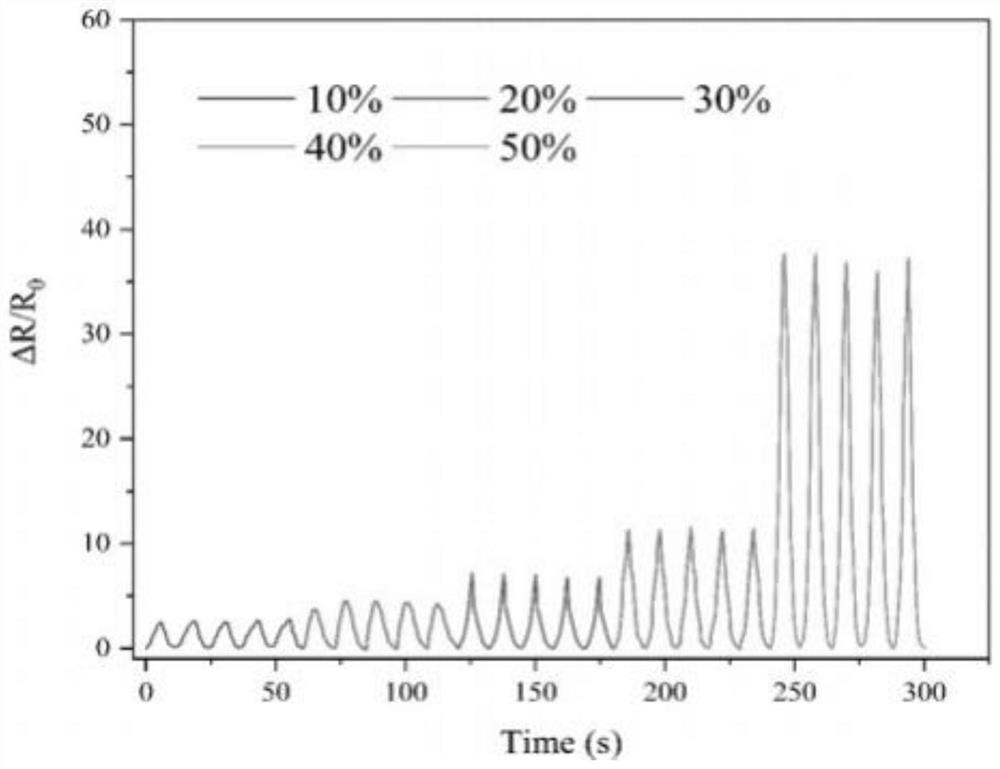

A composite film, high-sensitivity technology, applied in the field of application, can solve the problems of weak bonding force between flexible substrates and active materials, insufficient sensing range, and poor material durability, so as to maintain mechanical properties and short response time. , the effect of good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

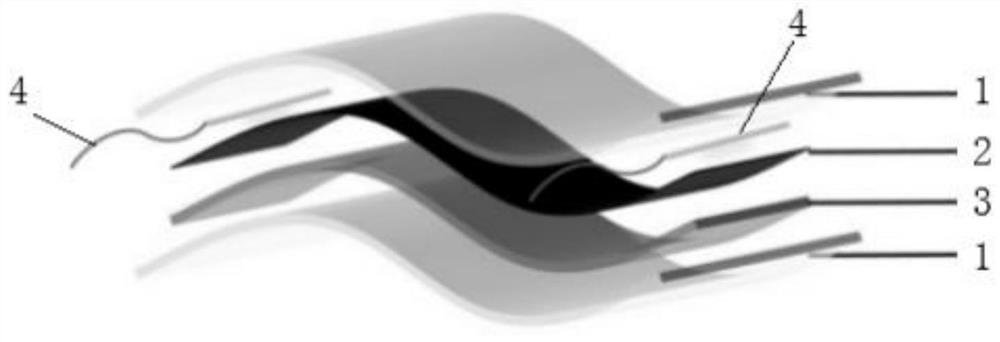

[0042] Example 1: The preparation method of the PDMS-MXene / TPU flexible stress sensor in this example is as follows:

[0043] Step 1, the flexible substrate is prepared by the film coating method. First, measure 5g of polyurethane (TPU) pellets, and 40ml of N,N-dimethylformamide (DMF) solution in the same amount, add them together to a three-necked bottle, and heat and stir At the same time, the water is condensed and refluxed, and the TPU glue is obtained in about one hour. Pour the glue solution into a beaker and vacuumize to remove air bubbles. The clear glass plate is then washed and dried. Take out the treated glue solution, pour the glue solution evenly on the glass plate, and place it on the automatic film coating machine to coat the film. After the film coating is completed, put the glass plate in a vacuum drying oven for drying, at 100°C After drying for 1 h, the TPU film was obtained after demoulding.

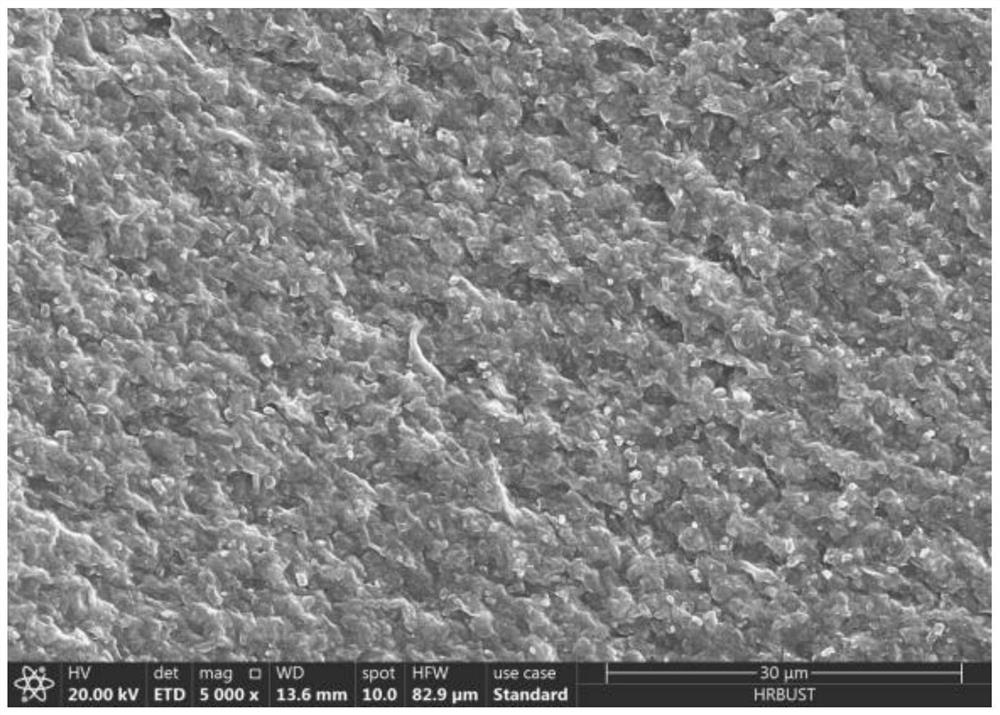

[0044] Step 2, the 2D Ti 3 C 2 MXene nanosheets were added ...

Embodiment 2

[0047] Embodiment 2: The preparation method of the PDMS-MXene / TPU flexible stress sensor in this embodiment is as follows:

[0048] Step 1, the flexible substrate is prepared by coating method. First, measure 4g of polyurethane (TPU) pellets and 30ml of N,N-dimethylformamide (DMF) solution, put them into a three-necked flask together, heat and stir while passing water to condense and reflux, and obtain in about one hour TPU glue. Pour the glue solution into a beaker and vacuumize to remove air bubbles. The clear glass plate is then washed and dried. Take out the processed glue solution, pour the glue solution evenly on the glass plate, and place it on the automatic film coating machine to coat the film. After the film coating is completed, put the glass plate in a vacuum drying oven for drying, at 80°C After drying for 2 hours, the TPU film was obtained after demoulding.

[0049] Step 2, the 2D Ti 3 C 2 MXene nanosheets were added to deionized water, and ultrasonically t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com